The Connection Between 800 Diaphragm Plates and Regulatory Compliance

The Connection Between 800 Diaphragm Plates and Regulatory Compliance Table of Contents 1. Introduction to 800 Diaphragm Plates 2. Understanding Regulatory Compliance in Industry 3. Importance of 800 Diaphragm Plates in Compliance 4. Design and Materials of 800 Diaphragm Plates 5. Applications of 800 Diaphragm Plates Across Various Industries 6. Key Compliance Standards fo

Understanding the Role of the 1500 Diaphragm Plate in Industrial Filtration Systems

The 1500 diaphragm plate is a pivotal element in the realm of industrial filtration systems, particularly within the category of filtering materials. Its design and functionality play a significant role in optimizing the filtration process, ensuring that contaminants are effectively removed from liquids and gases. Understanding the mechanics of the 1500 diaphragm plate can provide valuable insight

The Comprehensive Advantages of Implementing a 1200 Diaphragm Plate in Your Filtration System

The Comprehensive Advantages of Implementing a 1200 Diaphragm Plate in Your Filtration System In the realm of industrial filtration, the choice of components can significantly influence the performance and efficiency of the entire system. Among these components, the **1200 diaphragm plate** stands out for its unique advantages. This article explores the numerous benefits of using a 1200 diaphragm

Essential Filter Press Accessories for Enhanced Performance in Chemical Processing

In the chemical processing industry, filter presses play a crucial role in separating solids from liquids. However, to optimize their performance, it is essential to consider various filter press accessories. These accessories can significantly enhance operational efficiency, improve filter life, and reduce maintenance costs. Understanding the different types of accessories available can help prof

Critical Factors in Selecting a Filter Press Diaphragm for Your Application

Critical Factors in Selecting a Filter Press Diaphragm for Your Application Selecting the right **filter press diaphragm** for your specific application is a crucial decision that can significantly impact your operational efficiency and overall output. This article explores the vital factors to consider when making your selection, ensuring you choose a diaphragm that meets both your technical requ

Understanding Filter Press Plates: Key Components for Efficient Chemical Processing

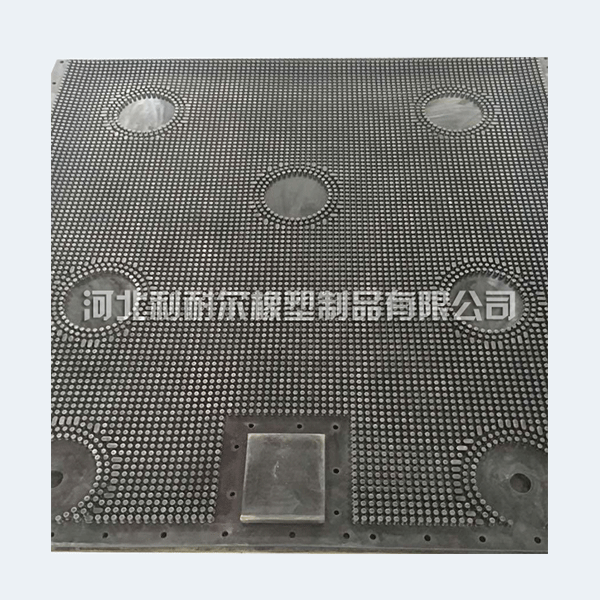

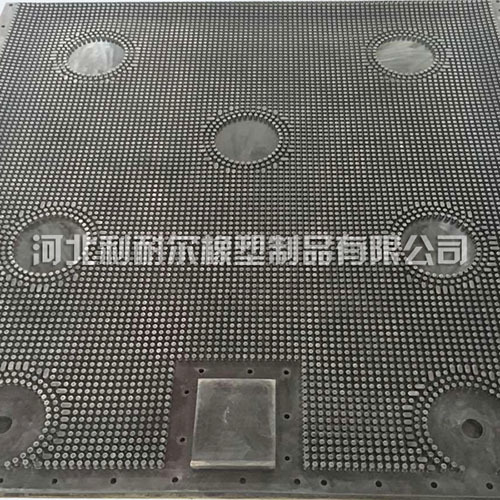

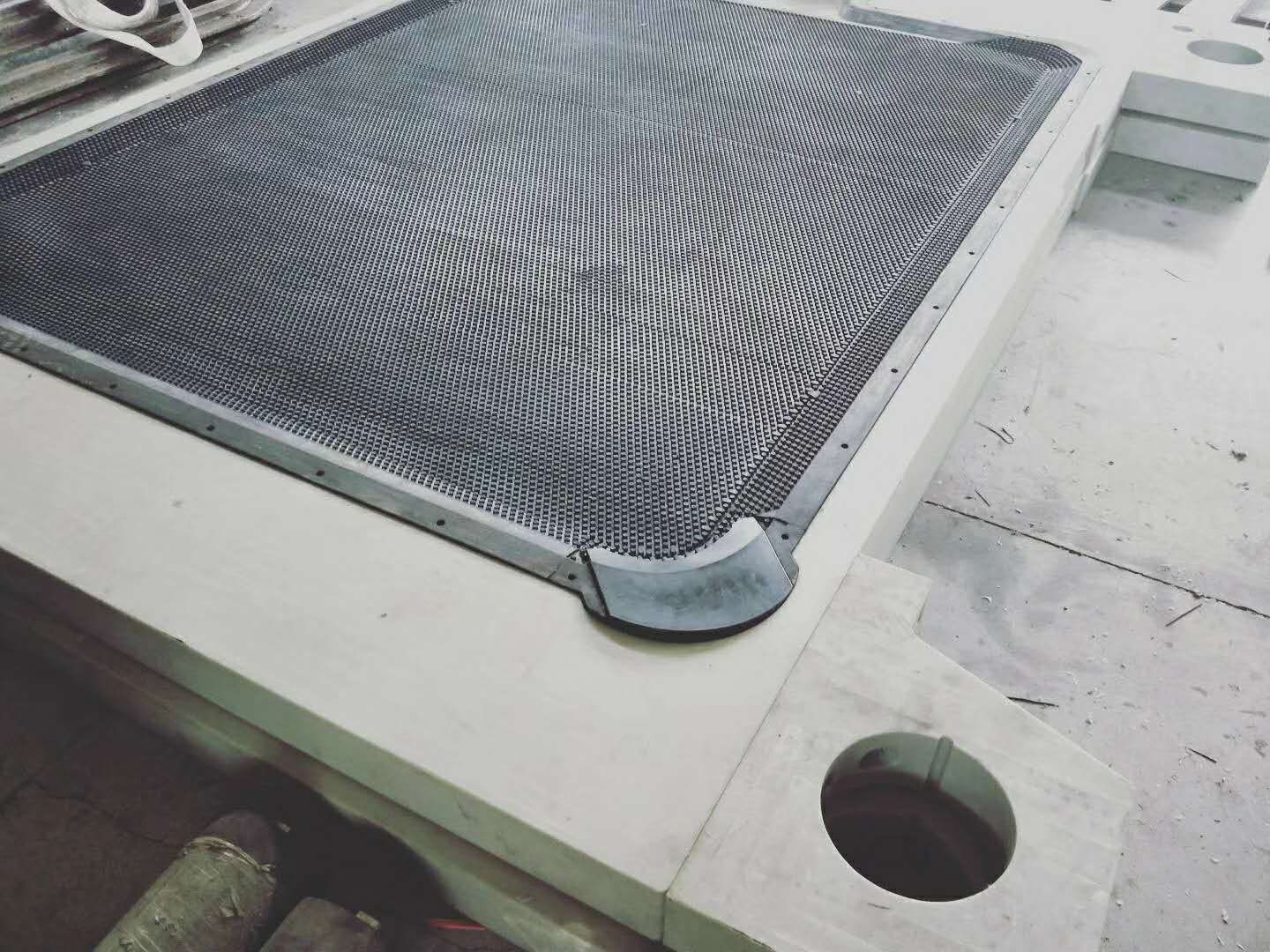

Filter press plates are integral components in various industrial filtration processes, particularly within the chemical and plastics sectors. They are designed to separate solids from liquids, making them crucial for operations such as wastewater treatment, slurry processing, and the production of certain plastic products. Understanding the functionality, types, and maintenance of filter press pl

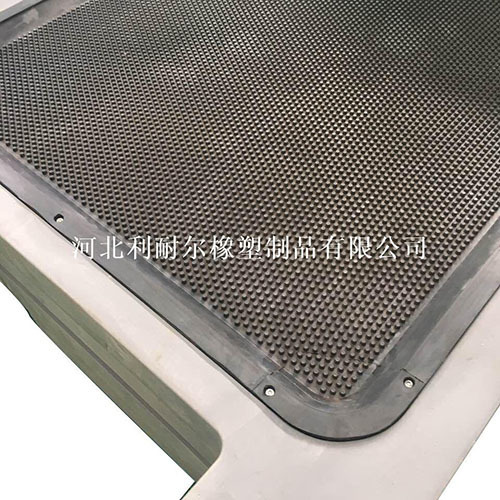

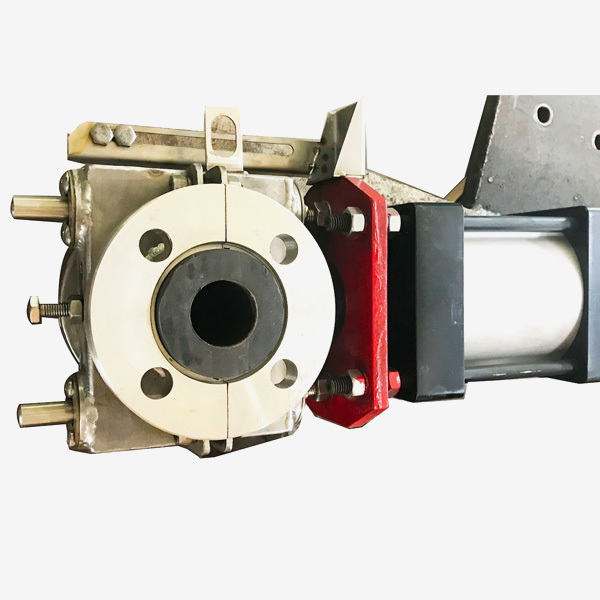

The Rubber Diaphragm provides flexible sealing, high pressure resistance, and reliable performance for hydraulic, pneumatic, and fluid control systems.

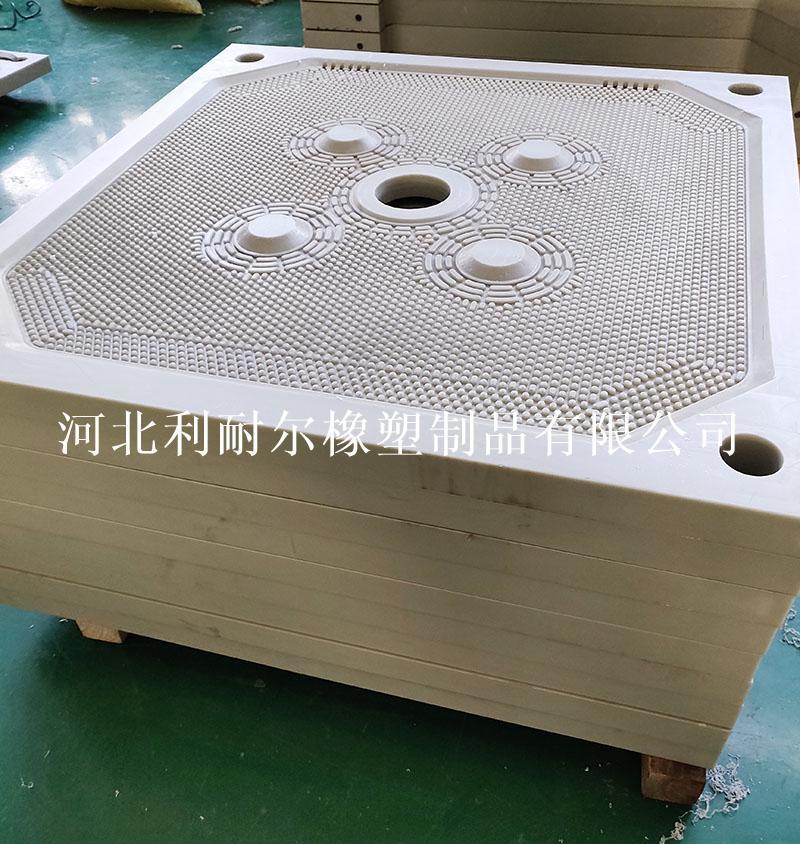

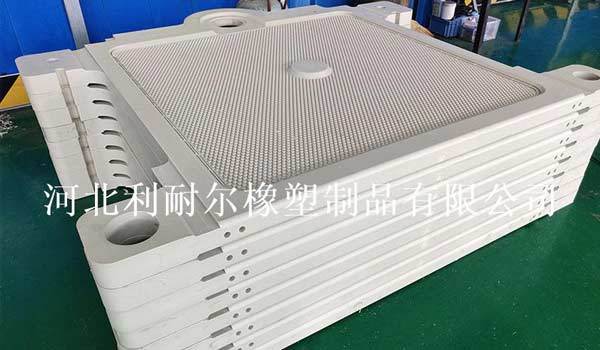

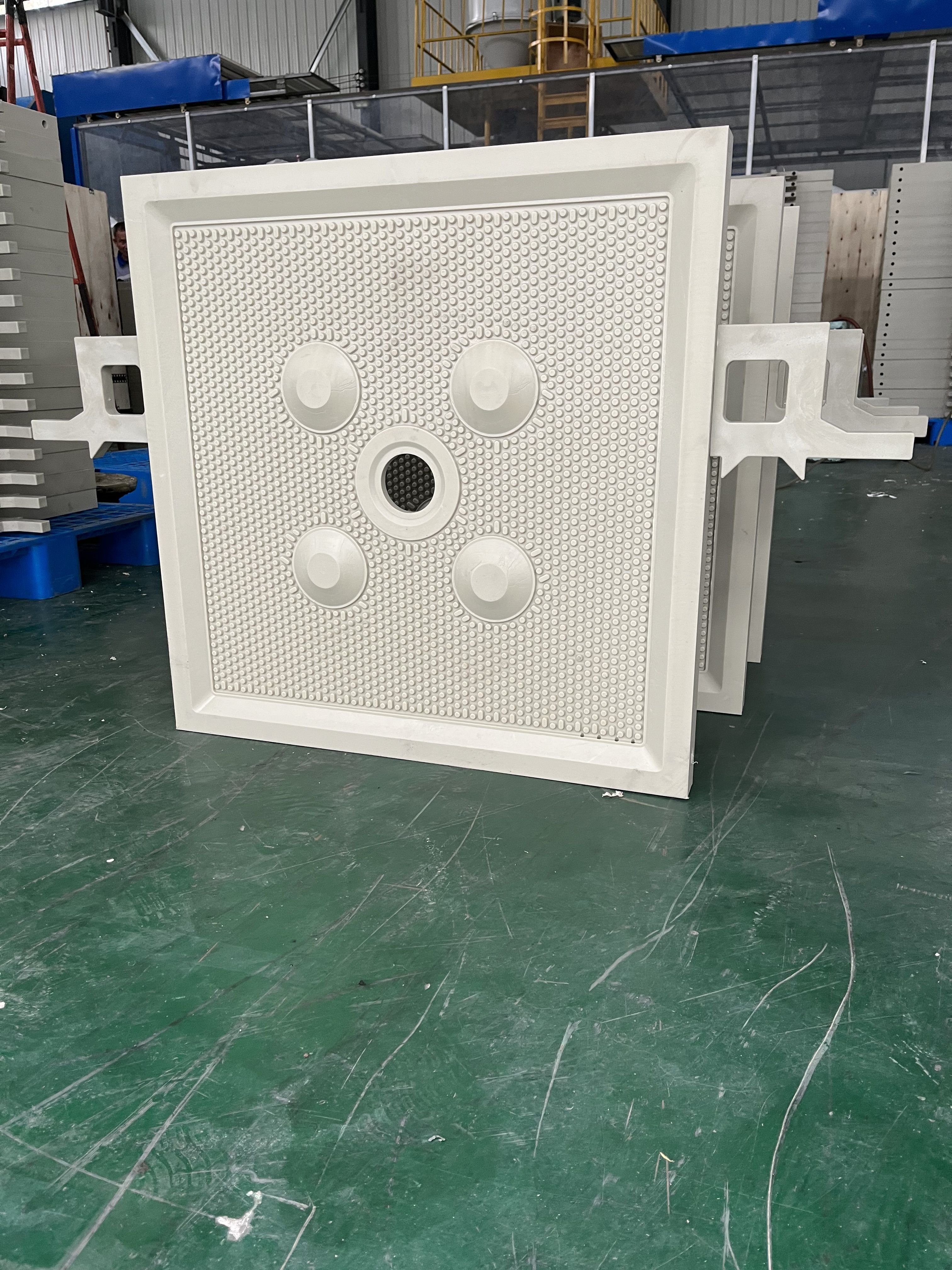

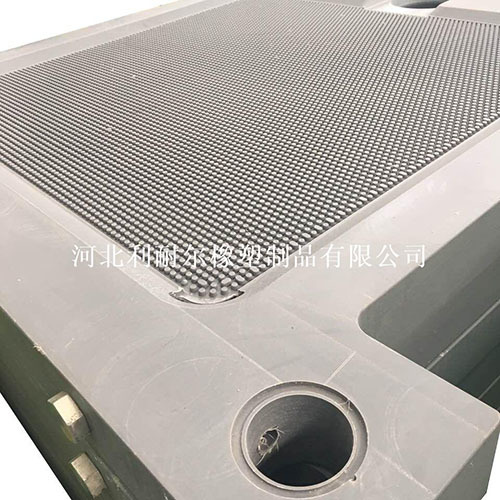

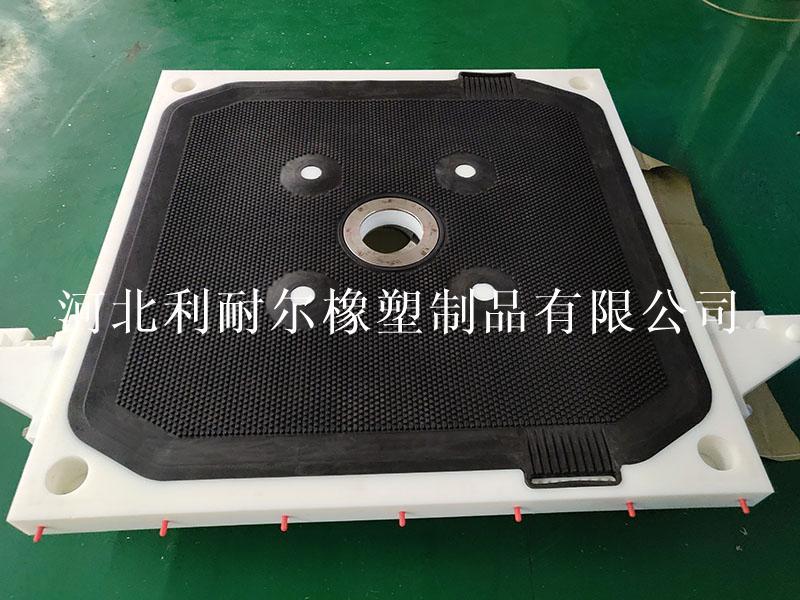

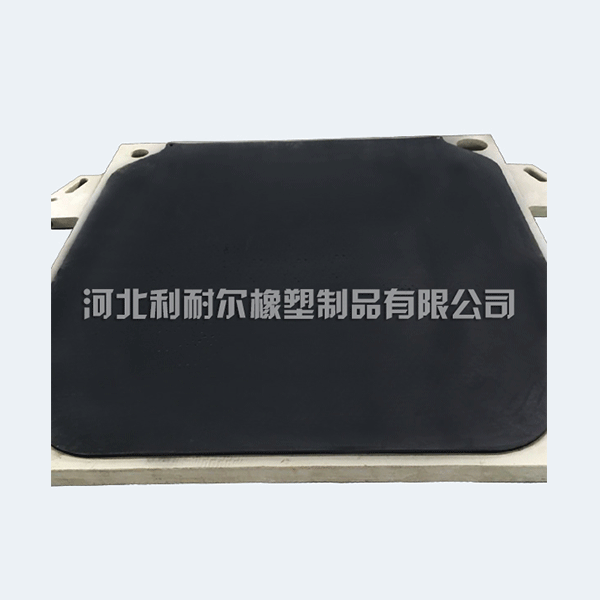

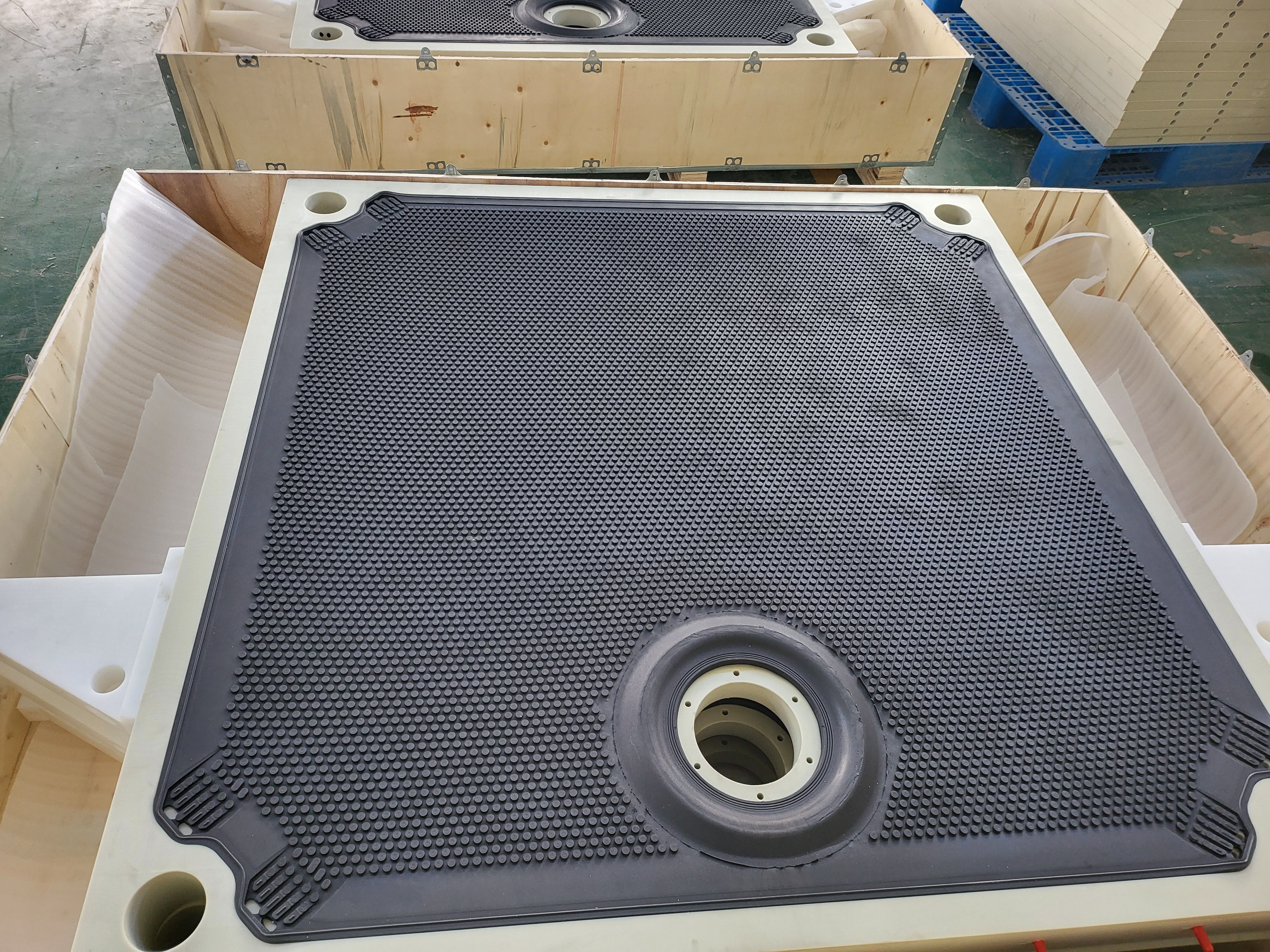

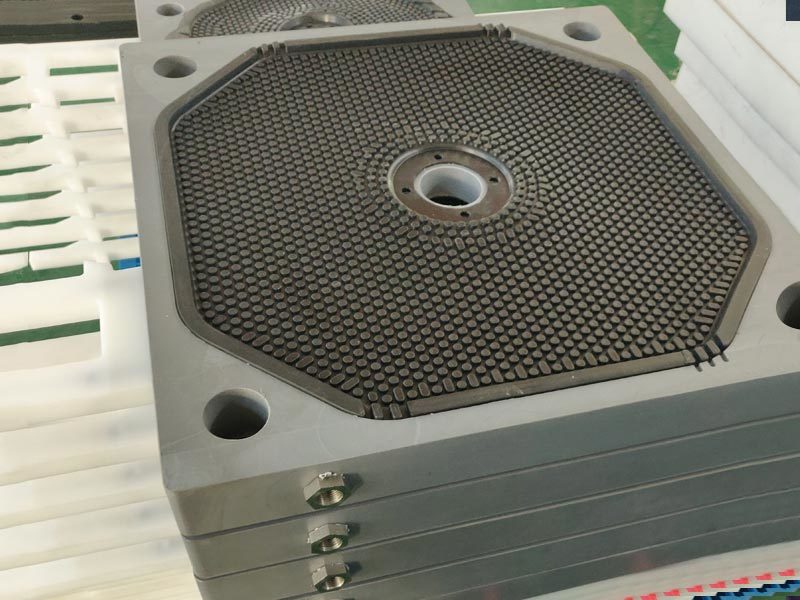

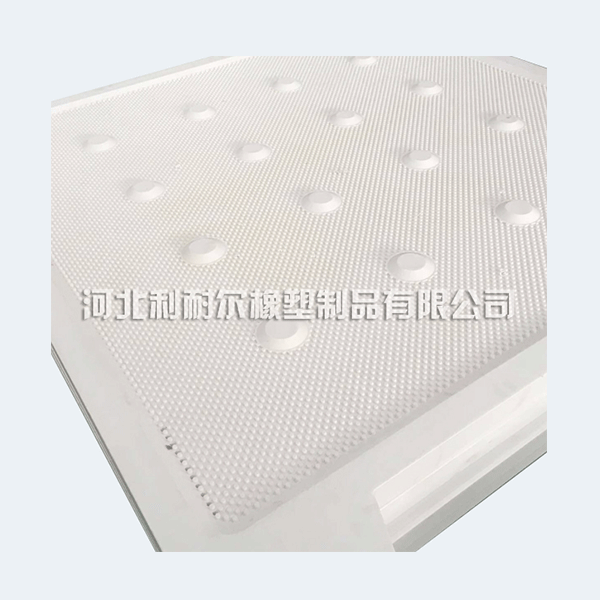

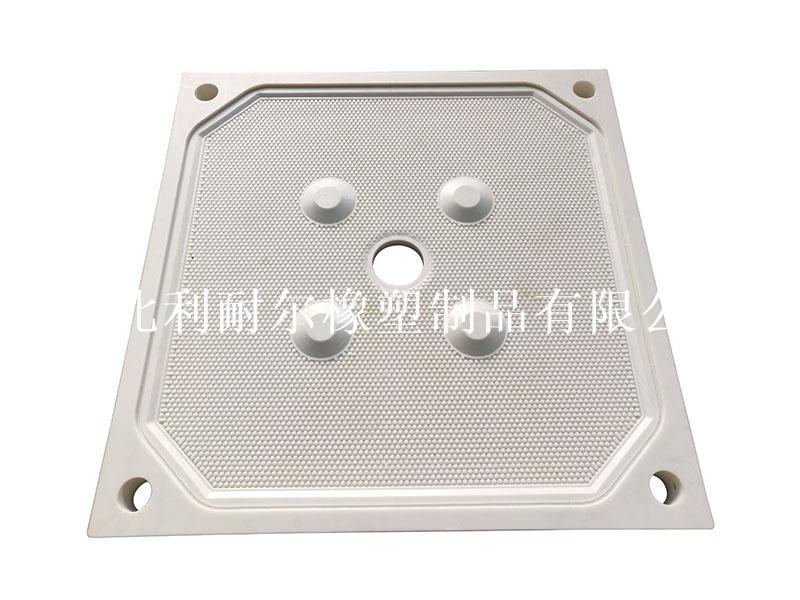

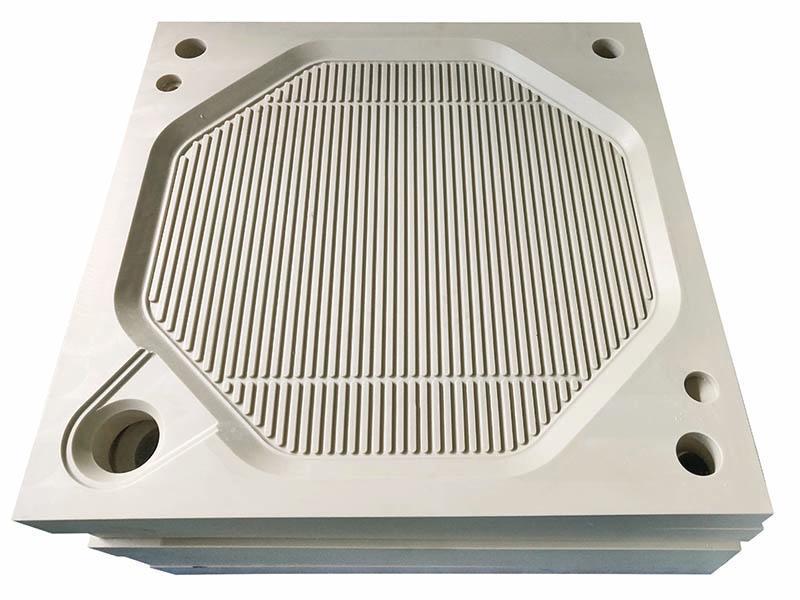

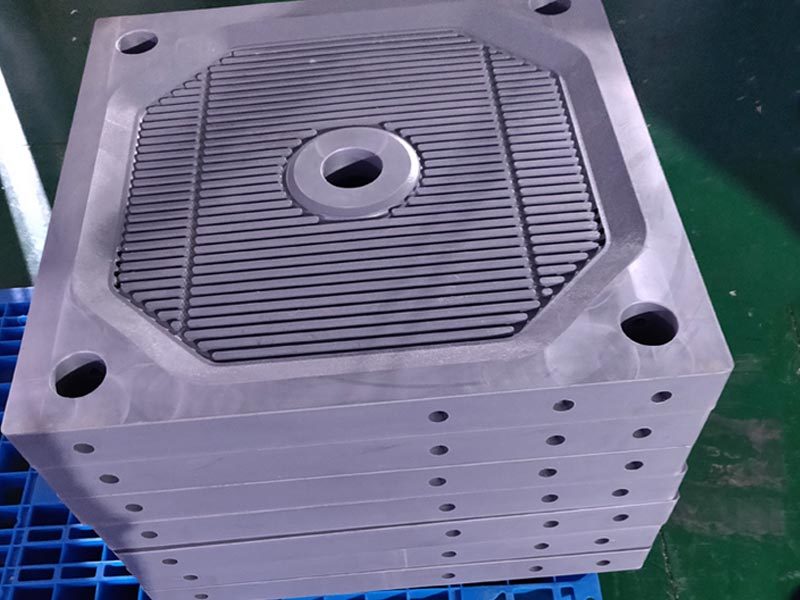

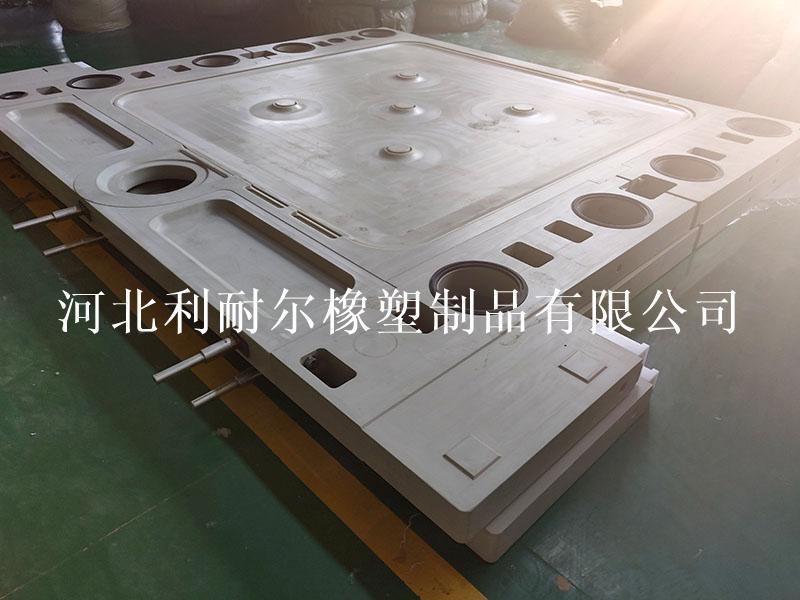

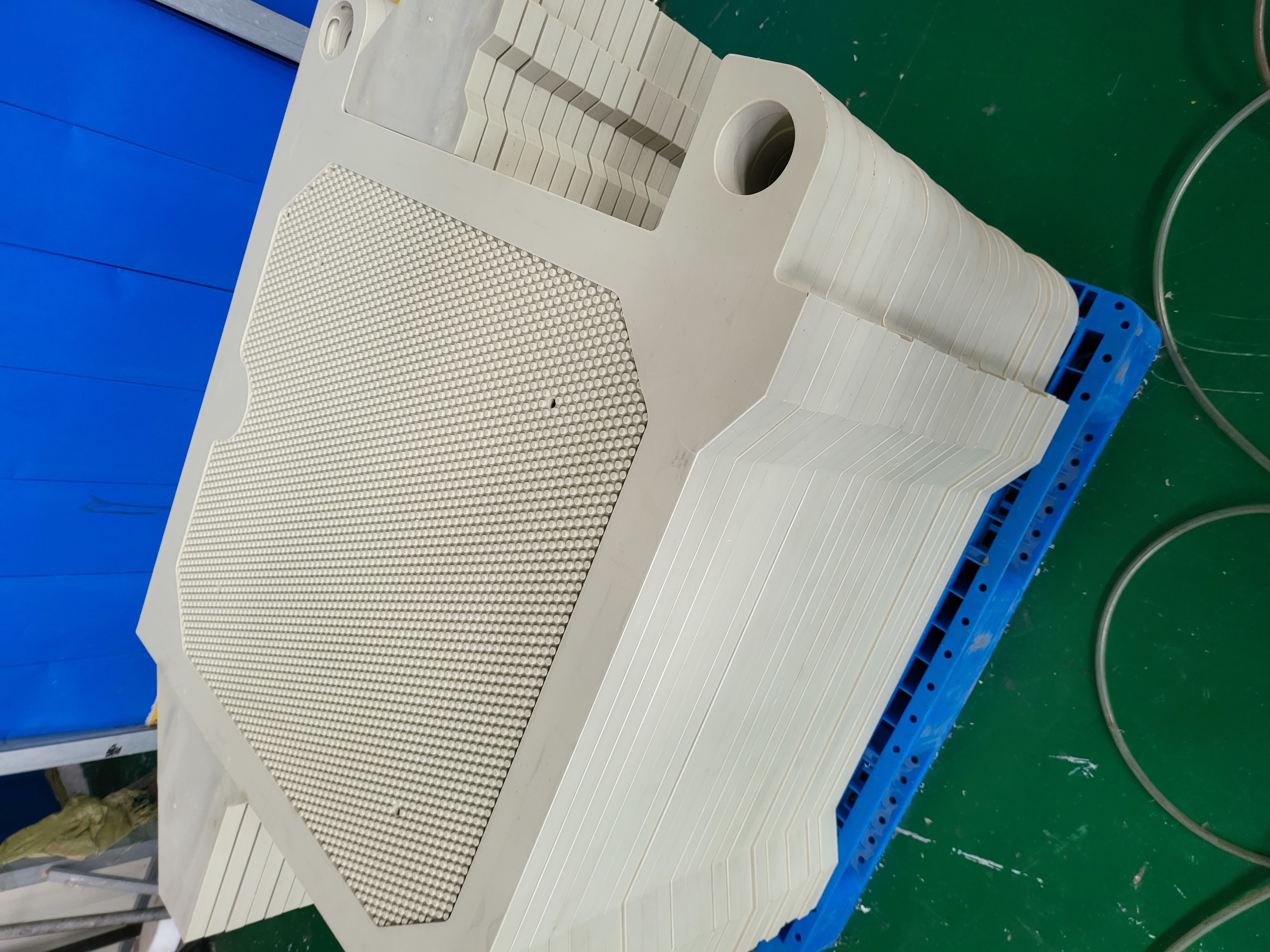

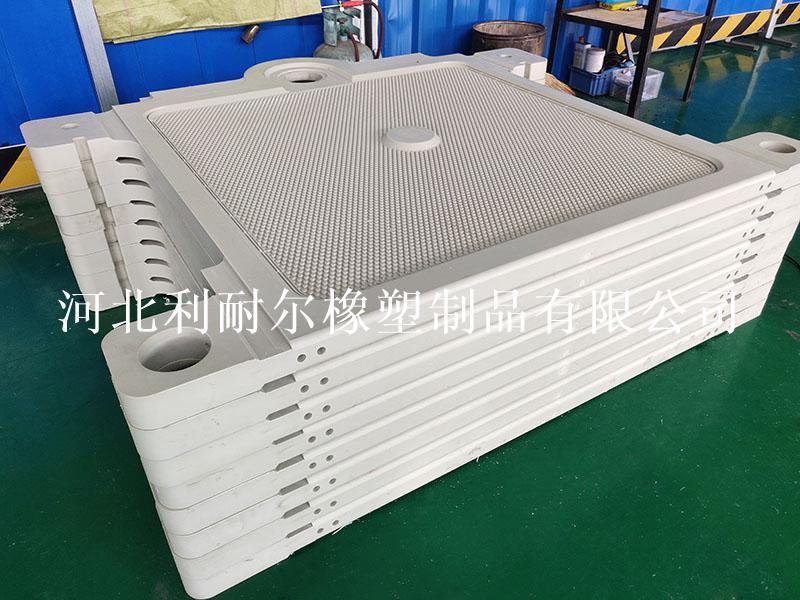

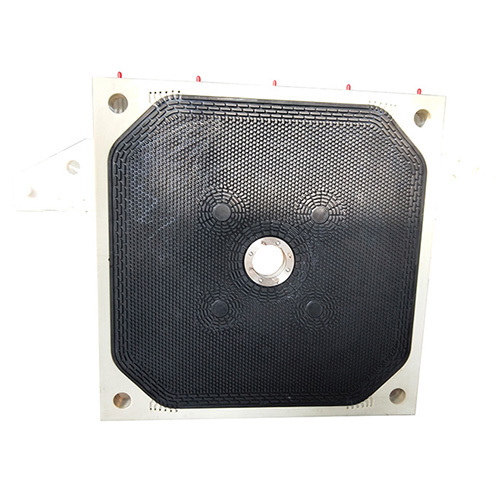

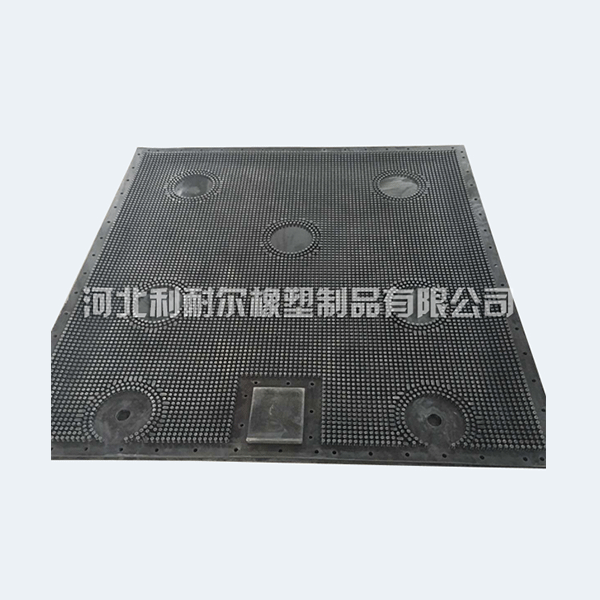

The Diaphragm Plate offers efficient dewatering, strong pressure resistance, and reliable performance for modern industrial filter press systems.

The Industrial Filter Press delivers efficient solid-liquid separation, high filtration accuracy, and reliable performance for various industrial processes.

Filter Press Grilles: Elevating Plastic Product Quality in Chemical Industries

Filter Press Grilles: Elevating Plastic Product Quality in Chemical Industries Table of Contents 1. Introduction to Filter Press Grilles 2. Understanding the Role of Filter Press Grilles in Chemical Processing 2.1 What Are Filter Press Grilles? 2.2 How Filter Press Grilles Work 3. The Importance of Quality in Plastic Products 3.1 Factors Affecting Plastic Quality 3.2 Quality Control in the Chemica

Understanding the Importance of Filter Press Sealing Strips in Industrial Applications

In industrial settings, filter presses are widely used for separating solids from liquids in a variety of applications, including wastewater treatment, food and beverage processing, and mineral processing. A critical component of the filter press is the sealing strip, which ensures that the system operates effectively without leaks. Proper sealing is essential for maintaining pressure, preventing

The Impact of a 1200 Filter Plate on Product Purity in Plastics

The Impact of a 1200 Filter Plate on Product Purity in Plastics Table of Contents 1. Introduction to Filter Plates in Plastics 2. The Importance of Product Purity in Plastics 3. Understanding Filter Plate Technology 4. Key Features of the 1200 Filter Plate 5. How a 1200 Filter Plate Works 6. The Impact of the 1200 Filter Plate on Product Purity 7. Benefits of Using a 1

Understanding the Importance of the 1100 Filter Plate in the Chemical and Plastics Industry

The 1100 filter plate is an essential component widely utilized in filtration processes within the chemical and plastics sector. It is designed to separate solid particles from liquids, ensuring that the final product meets the required purity standards. This is particularly important in the production of plastic materials, where contaminants can significantly affect the quality and performance of

The Role of 1000 Filter Plates in Wastewater Treatment Processes

The Role of 1000 Filter Plates in Wastewater Treatment Processes Introduction to Wastewater Treatment Wastewater treatment is an essential process that involves the removal of contaminants from wastewater, making it safe for discharge into the environment or for reuse. The importance of this process cannot be overstated, as it plays a critical role in protecting our water resources and public heal

Understanding the Significance of 800 Filter Plates in Chemical and Plastic Industries

In the chemical and plastic industries, the significance of filtration systems cannot be overstated, and one key component within these systems is the 800 filter plate. These filter plates are designed to effectively separate solid particles from liquids, ensuring that the end products meet the necessary quality standards. The 800 filter plate operates through a combination of physical barriers an

Transform Your Filtration Process with Advanced 630 Filter Plates: A Comprehensive Guide

Transform Your Filtration Process with Advanced 630 Filter Plates Table of Contents 1. Introduction to Advanced 630 Filter Plates 2. What Are Advanced 630 Filter Plates? 3. Key Features of Advanced 630 Filter Plates 4. Applications of Advanced 630 Filter Plates 5. Benefits of Using Advanced 630 Filter Plates 6. Comparison with Other Filter Plates 7. Installation and Ma

The Essential Guide to 400 Filter Plates: Enhancing Filtration Efficiency

In the realm of industrial filtration, the 400 filter plate stands out as an essential component for a variety of applications. These plates are designed to enhance the efficiency of liquid and gas filtration processes by providing a reliable barrier against contaminants, ensuring purity and operational efficiency. Understanding their functionality, advantages, and installation best practices can

Top Advantages of Implementing 880 Filter Plates in Your Operations

Top Advantages of Implementing 880 Filter Plates in Your Operations Table of Contents Introduction to 880 Filter Plates What Are 880 Filter Plates? Key Benefits of 880 Filter Plates Enhanced Efficiency in Filtration Processes Cost-Effectiveness and Long-Term Savings Improved Product Quality and Consistency Environmental Advantages of Using 880 Filter Plates

Maximize Efficiency with 800 x 800 Filter Plates: A Comprehensive Guide

In the realm of industrial filtration, the choice of equipment is crucial for maintaining efficiency and effectiveness in various applications. One component that plays a significant role in filtration systems is the filter plate, particularly the 800 x 800 size. These plates are designed to meet the demands of diverse industries, providing a reliable solution for separating solids from liquids an

How Filter Plates Enhance the Durability of Plastic Products

How Filter Plates Enhance the Durability of Plastic Products Table of Contents 1. Introduction to Filter Plates in Plastic Manufacturing 2. Understanding Filter Plates: Definition and Function 3. Why Durability Matters in Plastic Products 4. The Role of Filter Plates in Enhancing Durability 5. Types of Filter Plates Used in Plastic Production 6. Applications of Filter

Understanding Filter Plates: Essential Components in the Chemical and Plastics Industry

Filter plates are critical components used in various filtration processes within the chemical and plastics industries. Their primary function is to separate solids from liquids, effectively ensuring the purity and quality of the end product. By understanding the intricacies of filter plates, professionals in the field can enhance their operational efficiency and product performance. One of the mo

Exploring the Benefits of Using Diaphragm Plates in Industrial Applications

Exploring the Benefits of Using Diaphragm Plates in Industrial Applications Table of Contents 1. Introduction to Diaphragm Plates 2. What Are Diaphragm Plates? 3. Key Benefits of Using Diaphragm Plates 3.1 Enhanced Efficiency in Industrial Processes 3.2 Improved Durability and Longevity 3.3 Safety Features and Risk Reduction 4. Applications of Diaphragm Plates in Various Industr

Exploring the Versatility of the 1000 Diaphragm Plate in Industrial Filtration

In the realm of industrial filtration, the 1000 Diaphragm Plate stands out as a critical component. Designed for efficiency and durability, this plate is often utilized in various applications where precise filtration is paramount. Its primary function is to aid in the separation of particles from liquids, ensuring that the output meets the necessary quality standards for further processing or con

How to Conduct a Proper Inspection of Your 800 Diaphragm Plate: A Comprehensive Guide

How to Conduct a Proper Inspection of Your 800 Diaphragm Plate In the realm of industrial equipment and components, the 800 diaphragm plate plays a crucial role in various filtration processes. High efficiency and reliability are paramount in maintaining operational standards. Regular inspections of the diaphragm plate not only ensure optimal performance but also help identify potential issues bef

Understanding the 1500 Diaphragm Plate: Key Insights for Industrial Applications

The 1500 Diaphragm Plate is a vital element in the industrial filtration sector, particularly when it comes to optimizing the performance of filtration systems. This component plays a significant role in controlling fluid movement and enhancing the overall efficiency of filtration processes. Understanding its characteristics, applications, and maintenance can help professionals make informed decis

How to Choose the Right 1200 Diaphragm Plate for Your Industrial Needs

How to Choose the Right 1200 Diaphragm Plate for Your Industrial Needs Table of Contents Introduction to 1200 Diaphragm Plates Understanding Diaphragm Plates and Their Functionality Key Criteria for Selecting a 1200 Diaphragm Plate Material Considerations for Diaphragm Plates Understanding Size and Dimensions of 1200 Diaphragm Plates Performance Requirements for Your Diaph

Essential Insights into Filter Press Accessories for the Chemical Industry

In the chemical industry, particularly in the production of plastics and other related products, filter press accessories play a crucial role in ensuring effective filtration processes. These accessories, while often overlooked, are essential for maximizing the efficiency and lifespan of filter presses. Understanding the various components and their functions can significantly enhance operational

Enhancing Filtration Processes with Advanced Filter Press Diaphragms: A Comprehensive Guide

Enhancing Filtration Processes with Advanced Filter Press Diaphragms Table of Contents 1. Introduction to Filter Press Diaphragms 2. Understanding Filter Presses and Their Role in Filtration 3. Benefits of Advanced Filter Press Diaphragms 3.1 Improved Efficiency and Performance 3.2 Cost-Effectiveness and Reduced Downtime 3.3 Environmental I

Understanding Filter Press Plates: A Key Component in Chemical and Plastic Processing

Filter press plates are crucial components in the filtration process within the chemical and plastic manufacturing sectors. They serve as the backbone of filter presses, which are widely used to separate solids from liquids in various processes, including wastewater treatment and product purification. Understanding the features and functionality of filter press plates can greatly enhance operation

Exploring the Benefits of Advanced Filter Press Grille Technology: A Comprehensive Guide

Exploring the Benefits of Advanced Filter Press Grille Technology Table of Contents 1. Introduction to Filter Press Grille Technology 2. Understanding the Basics of Filter Press Operation 3. Key Advantages of Advanced Filter Press Grille Technology 4. Enhanced Operational Efficiency 4.1. Improved Filtration Process 4.2. Increased Throughput and Productivity 5. Cost-Effectiveness and Long-Term Savi

Understanding the Importance of Filter Press Sealing Strips in Industrial Applications

In the realm of industrial equipment and components, filter press sealing strips are essential for ensuring effective operation and longevity of filtration systems. These sealing strips are designed to provide a tight seal between the plates of a filter press, which is crucial for preventing leaks and maintaining the integrity of the filtration process. The primary function of a filter press seali

What Makes a 1200 Filter Plate Stand Out in Chemical Applications?

What Makes a 1200 Filter Plate Stand Out in Chemical Applications? Introduction to Filter Plates in the Chemical Industry In the chemical processing industry, the importance of filtration cannot be overstated. Filtration is fundamental for separating solids from liquids, ensuring product purity, and maintaining operational efficiency. Among the various types of filter plates available, the **1200

Understanding the Significance of the 1100 Filter Plate in Chemical and Plastics Industries

In the chemical and plastics industries, the functionality and efficiency of production processes are paramount. One critical component that has gained attention for its performance and reliability is the 1100 filter plate. Understanding the characteristics and applications of the 1100 filter plate can significantly aid in optimizing your operations. The 1100 filter plate is specifically designed

Top Features to Consider When Choosing 1000 Filter Plates

Introduction to Filter Plates in Industrial Applications In the world of industrial filtration, **filter plates** play a crucial role in ensuring the efficiency and effectiveness of various processes. Whether used in chemical processing, wastewater treatment, or food and beverage production, selecting the right filter plates is vital. This article delves into the **top features to consider when ch

Understanding the Importance of the 800 Filter Plate in Chemical Processing

In the chemical industry, efficiency and purity in processing are paramount. One component that plays a vital role in achieving these objectives is the 800 filter plate. Often utilized in various filtration systems, the 800 filter plate is designed to enhance the separation of solids from liquids in diverse chemical applications. Its primary function is to ensure that the final products maintain h

Maximizing Filtration: Why Every Industry Needs a Reliable 630 Filter Plate

Maximizing Filtration: Why Every Industry Needs a Reliable 630 Filter Plate Table of Contents Introduction to the 630 Filter Plate What is a 630 Filter Plate? The Importance of Efficient Filtration in Industries Advantages of Using 630 Filter Plates Applications of 630 Filter Plates Across Industries Choosing the Right Filter Plate for Your Needs Maintenance and Care f

Understanding Scraper Technology in the Rubber Industry

In the rubber and its products sector, particularly in the realm of unconventional rubber products, the term "scraper" refers to specialized equipment designed to optimize the manufacturing process. This technology plays a crucial role in ensuring product quality and enhancing operational efficiency. Scrapers are mechanical devices used to remove or manage materials during various stages of produc

Understanding the Different Types of O-Ring Materials for Sealing Components

Understanding the Different Types of O-Ring Materials for Sealing Components When it comes to industrial applications, the selection of appropriate sealing materials plays a critical role in the reliability and efficiency of machinery. Among these materials, **O-rings** stand out due to their versatility and effectiveness in preventing leaks. This article will explore the various types of O-ring m

Understanding the Importance and Applications of 400 Filter Plates in Industrial Filtration

In industrial settings, the efficiency of filtration processes can significantly impact overall productivity and product quality. One integral component in many filtration systems is the 400 filter plate. These plates serve as a crucial part of the filtration process, providing a reliable method to separate solids from liquids or gases. Understanding the characteristics and applications of 400 fil

Understanding the Functionality and Benefits of Pinch Valves in Industrial Applications

Pinch valves are specialized devices used to regulate the flow of fluids, particularly in industrial applications. They are known for their simple yet effective design, which allows for the smooth control of the flow and pressure of various substances. The core mechanism of a pinch valve involves a flexible tube or sleeve that can be pinched closed or opened, thus controlling the flow of the mediu

Understanding the Role of 880 Filter Plates in Modern Industrial Applications

Understanding the Role of 880 Filter Plates in Modern Industrial Applications Table of Contents Introduction to 880 Filter Plates Construction and Design of 880 Filter Plates How 880 Filter Plates Function in Filtration Systems Applications of 880 Filter Plates Across Industries Advantages of Using 880 Filter Plates Maintenance Best Practices for 880 Filter Plates Case Studies: Succ

Enhance the Efficiency of Your Filter Press with Cylinder Seals: A Comprehensive Guide

Enhance the Efficiency of Your Filter Press with Cylinder Seals In the realm of industrial filtration, the **filter press** stands as a pivotal piece of equipment, crucial for separating solids from liquids. While numerous factors contribute to the operational efficacy of a filter press, one component often overlooked is the **cylinder seal**. This article delves into how cylinder seals can signif

Protecting Workers: Quality Seals for Coal Mines

Protecting Workers: Quality Seals for Coal Mines Introduction to Seals in Coal Mining In the coal mining industry, safety is paramount. With challenging environments and numerous hazards, ensuring the protection of workers is a top priority. One critical component that often goes unnoticed yet plays an essential role in maintaining workplace safety is the seal. Quality seals are vital for preven

In the industrial filtration landscape, the role of filter plates cannot be overstated, especially the 800 x 800 filter plates. These components are crucial for effective filtration in various processes, ensuring that contaminants and particulates are removed efficiently. Understanding the specifications and applications of these filter plates can significantly enhance operational performance acro

Choosing the Right Skeleton Oil Seal for Your Industrial Needs

Choosing the Right Skeleton Oil Seal for Your Industrial Needs Table of Contents Introduction to Skeleton Oil Seals What is a Skeleton Oil Seal? Types of Skeleton Oil Seals Nitrile Rubber Seals Fluoroelastomer Seals Silicone Seals Applications of Skeleton Oil Seals in Industry Key Factors to Consider When Choosing Skeleton

Maximizing Piston Lifespan with Combination Seals: A Comprehensive Guide

Maximizing Piston Lifespan with Combination Seals In the world of industrial machinery, the efficiency and longevity of components are paramount. One critical aspect that impacts performance is the sealing systems used in pistons. **Combination seals** have emerged as a leading solution for maximizing piston lifespan. This article delves into the various aspects of combination seals, their benefit

Understanding the Importance of Quality Filter Plates in Industrial Applications

Understanding the Importance of Quality Filter Plates in Industrial Applications Table of Contents 1. Introduction to Filter Plates in Industry 2. What Are Filter Plates? 3. Types of Filter Plates Used in Industrial Applications 4. Materials Used in Manufacturing Filter Plates 5. Benefits of Using Quality Filter Plates 6. Maintenance and Care for Filter Plates 7. Commo

Enhance Engine Performance and Minimize Leaks with State-of-the-Art Cylinder Seals

Enhance Engine Performance and Minimize Leaks with State-of-the-Art Cylinder Seals Table of Contents 1. Introduction to Cylinder Seals and Engine Performance 2. The Importance of Cylinder Seals in Engine Functionality 3. Types of Cylinder Seals: A Comprehensive Overview - 3.1 Rubber Seals: Versatile and Cost-Effective - 3.2 Metal Seals: Durability in Extreme Conditions - 3.3 Com

Understanding Filter Plates: Essential Components in Chemical and Plastic Industries

Filter plates play a critical role in various industrial processes, particularly within the chemical and plastic manufacturing industries. These components are primarily utilized in filtration systems, where they act as a barrier to separate solid particles from liquids or gases, ensuring that the final product meets the desired quality standards. Understanding the functions and applications of fi

The Pros and Cons of Using FAFAIFI Cloth in Industrial Applications

The Pros and Cons of Using FAFAIFI Cloth in Industrial Applications Introduction to FAFAIFI Cloth FAFAIFI cloth is rapidly gaining traction in various industrial applications due to its unique properties and versatility. As industries look for innovative materials that can enhance productivity and performance, FAFAIFI cloth has emerged as a promising option. In this article, we will delve into the

Extend the Lifespan of Your Filter Press with Quality Seals: A Comprehensive Guide

Extend the Lifespan of Your Filter Press with Quality Seals In industrial applications, the filter press is a vital piece of equipment, playing a crucial role in the separation of liquids and solids. However, the longevity and efficiency of your filter press heavily rely on the quality of seals used in its operation. In this article, we will explore how investing in quality seals can extend the li

The Role of Diaphragm Plates in Modern Manufacturing Processes Manufacturing processes today are more sophisticated than ever, driven by technological advancements and the demand for efficiency. One of the key components that contribute significantly to these processes is the diaphragm plate. While often overlooked, diaphragm plates play a pivotal role in various applications, from fluid control t

Effortless Control and Reliable Performance: Pneumatic Pinch Valves

Effortless Control and Reliable Performance: Pneumatic Pinch Valves Table of Contents Introduction to Pneumatic Pinch Valves How Pneumatic Pinch Valves Work Key Components of Pneumatic Pinch Valves Benefits of Using Pneumatic Pinch Valves Applications of Pneumatic Pinch Valves Maintenance Tips for Pneumatic Pinch Valves Troubleshooting Common

The Essential Guide to 1000 Diaphragm Plates in Industrial Filtration

In the realm of industrial filtration, the 1000 diaphragm plate stands out as a crucial component. These plates are primarily designed to enhance the efficiency and effectiveness of various filtration systems. Understanding the role of diaphragm plates is essential for professionals seeking to optimize their filtration processes, ensuring high-quality output and operational reliability. The 1000 d

The Critical Importance of VPA20 Diaphragm Plate in Enhancing Industrial Equipment Efficiency

The Critical Importance of VPA20 Diaphragm Plate in Enhancing Industrial Equipment Efficiency Table of Contents 1. Introduction to the VPA20 Diaphragm Plate 2. Understanding the Functionality of Diaphragm Plates 2.1 What is a Diaphragm Plate? 2.2 How VPA20 Differs from Other Diaphragm Plates 3. Key Benefits of VPA20 Diaphragm Plates in Industrial Equipment 3.1 Enhanced Efficiency in Operations 3.2

Enhancing Filtration Performance with Advanced Filtrate Collectors: A Comprehensive Guide

Enhancing Filtration Performance with Advanced Filtrate Collectors Table of Contents 1. Introduction to Filtration Technology 2. Importance of Filtration in Industrial Applications 3. What Are Advanced Filtrate Collectors? 4. Types of Advanced Filtrate Collectors 5. Benefits of Using Advanced Filtrate Collectors 6. Applications of Advanced Filtrate Collectors 7. Best Practices for E

The Critical Role of Quality Control in 800 Diaphragm Plate Production Understanding 800 Diaphragm Plates In the world of industrial equipment, **800 diaphragm plates** play a crucial role in various applications, including filtration, separation, and pressure regulation. These plates are primarily used in systems that require precise control over fluid dynamics and pressure levels. Understanding

Choosing the Right Horizontal Diaphragm Filter Press for Your Industrial Equipment Needs

Choosing the Right Horizontal Diaphragm Filter Press for Your Industrial Equipment Needs Table of Contents 1. Introduction to Horizontal Diaphragm Filter Presses 2. What is a Horizontal Diaphragm Filter Press? 3. Benefits of Using Horizontal Diaphragm Filter Presses 4. Industrial Applications of Horizontal Diaphragm Filter Presses 5. Key Features to Consider When Choosing

Understanding the Importance of the 1500 Diaphragm Plate in Industrial Filtration

The 1500 Diaphragm Plate is a specialized filtration material widely used in industrial applications. Its design and functionality play a vital role in improving the effectiveness of filtration processes across different sectors. One of the primary advantages of the 1500 Diaphragm Plate is its ability to withstand high pressures and temperatures, making it suitable for demanding environments. In i

Unlocking Efficiency: How Horizontal Filter Boards Enhance Manufacturing Productivity

How Horizontal Filter Boards Improve Productivity in Manufacturing Understanding Horizontal Filter Boards Horizontal filter boards are essential components in various manufacturing sectors, particularly in filtration processes. These boards are designed to separate solids from liquids efficiently, ensuring that the final product meets stringent quality standards. By utilizing a series of porous ma