Understanding the Importance of the 1500 Diaphragm Plate in Industrial Filtration

Release time:

2025-05-22

The 1500 Diaphragm Plate is a specialized filtration material widely used in industrial applications. Its design and functionality play a vital role in improving the effectiveness of filtration processes across different sectors. One of the primary advantages of the 1500 Diaphragm Plate is its ability to withstand high pressures and temperatures, making it suitable for demanding environments. In i

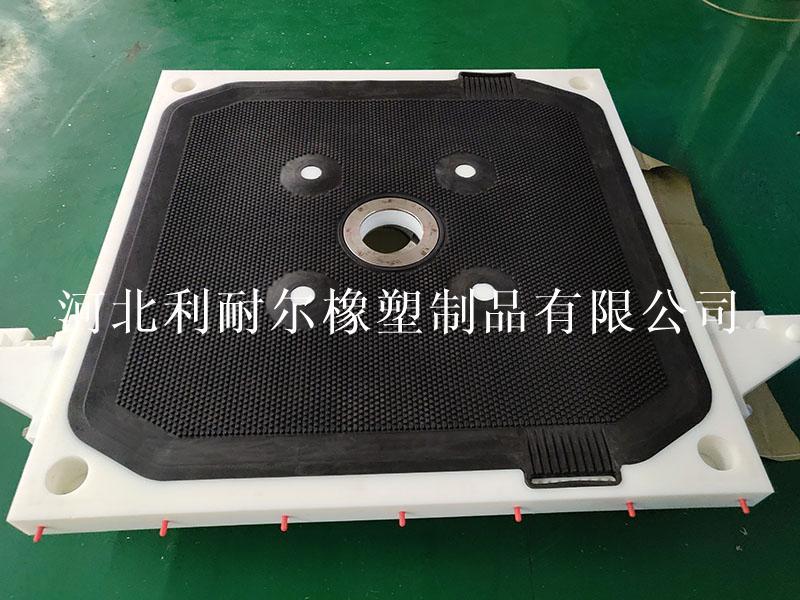

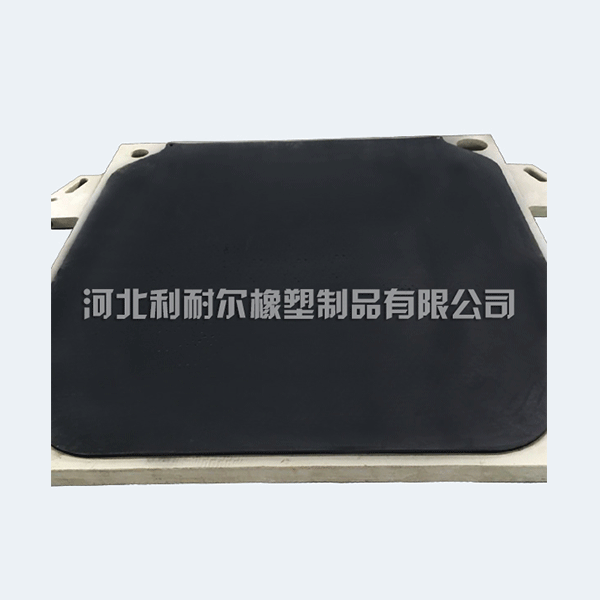

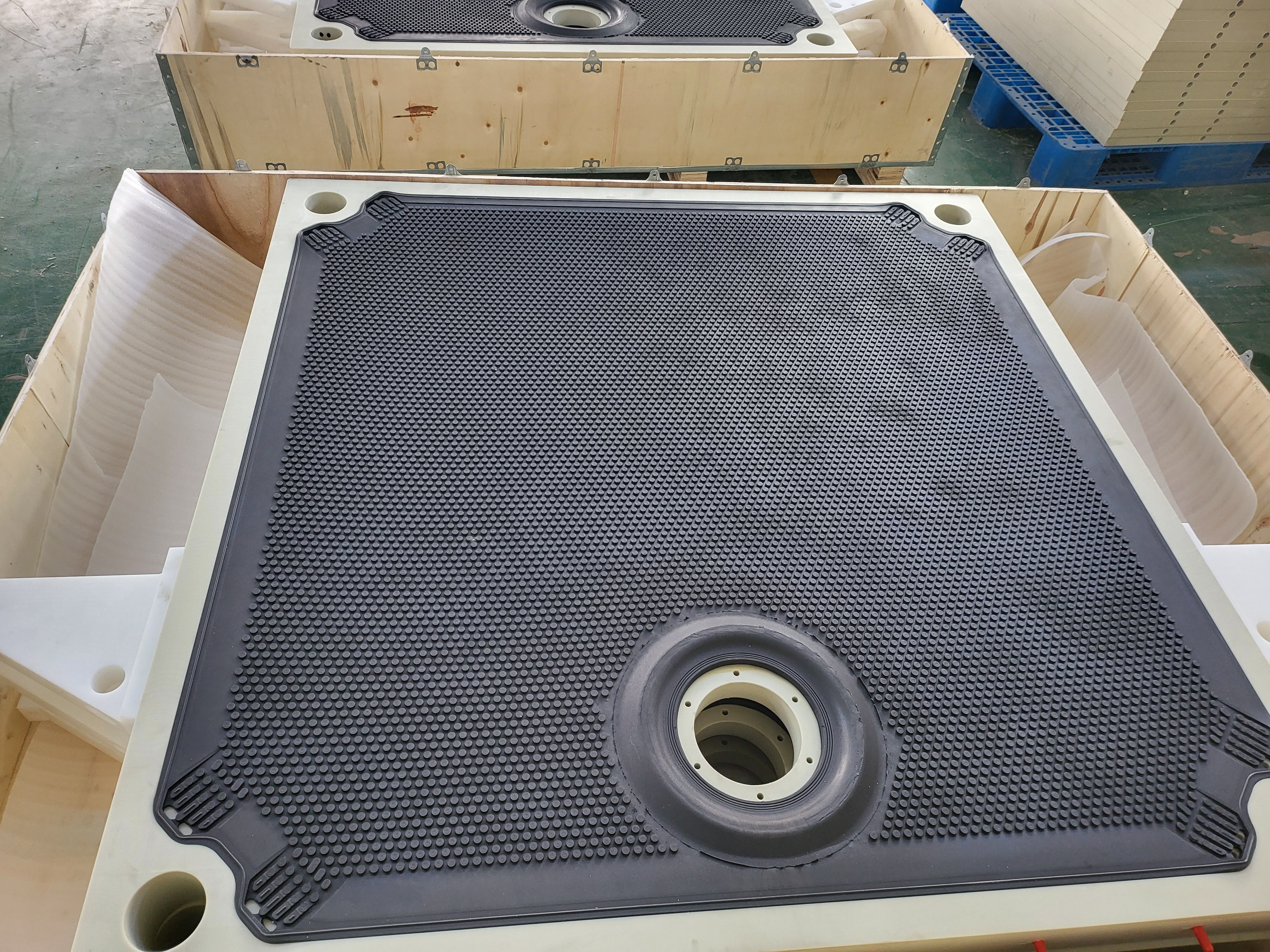

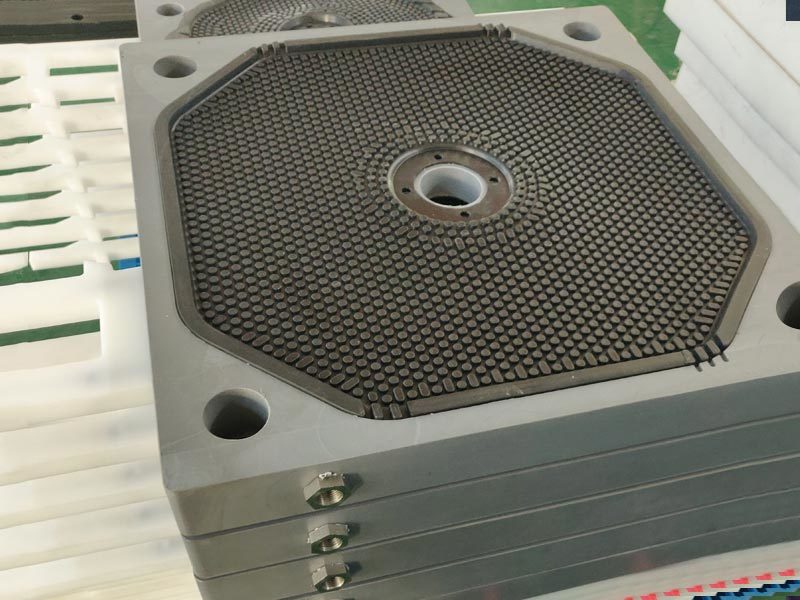

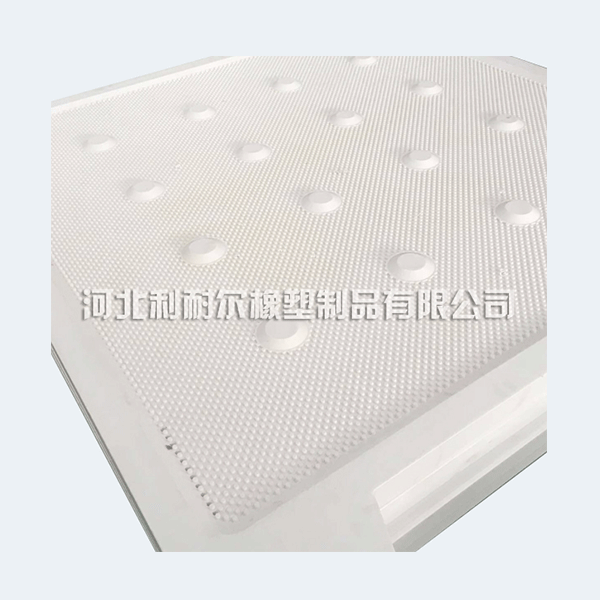

The 1500 Diaphragm Plate is a specialized filtration material widely used in industrial applications. Its design and functionality play a vital role in improving the effectiveness of filtration processes across different sectors. One of the primary advantages of the 1500 Diaphragm Plate is its ability to withstand high pressures and temperatures, making it suitable for demanding environments.

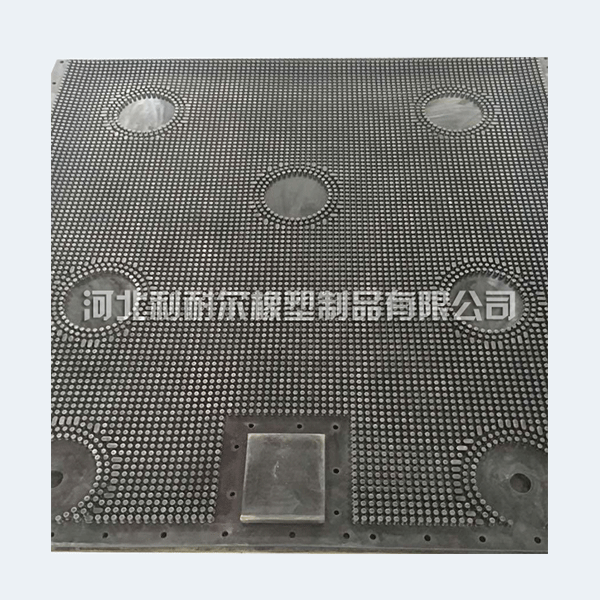

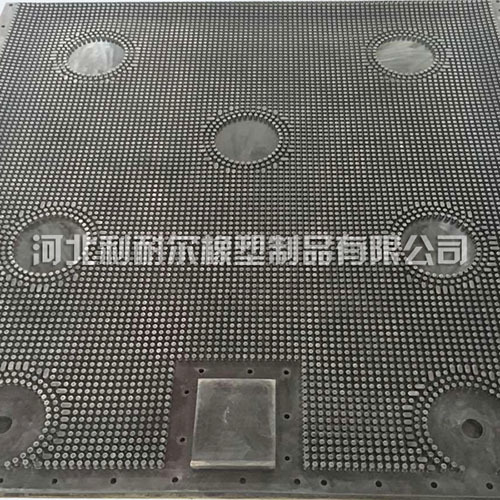

In industrial filtration, diaphragm plates serve as a barrier that separates contaminants from the desired product. The 1500 Diaphragm Plate is engineered to provide superior filtration performance, ensuring that even the smallest particles are effectively captured. This is crucial in maintaining product quality and preventing contamination, which can lead to costly downtime and maintenance.

The material composition of the 1500 Diaphragm Plate is another factor that contributes to its effectiveness. Typically made from durable synthetic materials, it offers resistance to chemicals and mechanical wear. This durability means that the diaphragm plate can perform consistently over a long period, reducing the need for frequent replacements and thereby optimizing operational efficiency.

Applications of the 1500 Diaphragm Plate are prevalent in various industrial settings, including petrochemical, water treatment, and food processing industries. In these sectors, the diaphragm plate is often employed in systems such as pressure filters, membrane filtration units, and other advanced filtration assemblies. By utilizing the 1500 Diaphragm Plate in these systems, businesses can achieve higher purity levels and improve overall process efficiency.

Moreover, the 1500 Diaphragm Plate's design facilitates easy installation and maintenance. This user-friendly feature is essential for minimizing downtime during maintenance procedures, allowing operations to continue smoothly. Additionally, understanding the specific requirements of your filtration system can help in selecting the right diaphragm plate that fits your needs.

In conclusion, the 1500 Diaphragm Plate is an indispensable component in the realm of industrial filtration. Its ability to enhance filtration effectiveness, coupled with its robust material characteristics, makes it a preferred choice for many industries. By integrating the 1500 Diaphragm Plate into your filtration systems, you can ensure optimal performance and extend the lifespan of your equipment. Whether you are in the petrochemical industry or involved in water treatment processes, the right diaphragm plate can significantly impact your operational success.

In industrial filtration, diaphragm plates serve as a barrier that separates contaminants from the desired product. The 1500 Diaphragm Plate is engineered to provide superior filtration performance, ensuring that even the smallest particles are effectively captured. This is crucial in maintaining product quality and preventing contamination, which can lead to costly downtime and maintenance.

The material composition of the 1500 Diaphragm Plate is another factor that contributes to its effectiveness. Typically made from durable synthetic materials, it offers resistance to chemicals and mechanical wear. This durability means that the diaphragm plate can perform consistently over a long period, reducing the need for frequent replacements and thereby optimizing operational efficiency.

Applications of the 1500 Diaphragm Plate are prevalent in various industrial settings, including petrochemical, water treatment, and food processing industries. In these sectors, the diaphragm plate is often employed in systems such as pressure filters, membrane filtration units, and other advanced filtration assemblies. By utilizing the 1500 Diaphragm Plate in these systems, businesses can achieve higher purity levels and improve overall process efficiency.

Moreover, the 1500 Diaphragm Plate's design facilitates easy installation and maintenance. This user-friendly feature is essential for minimizing downtime during maintenance procedures, allowing operations to continue smoothly. Additionally, understanding the specific requirements of your filtration system can help in selecting the right diaphragm plate that fits your needs.

In conclusion, the 1500 Diaphragm Plate is an indispensable component in the realm of industrial filtration. Its ability to enhance filtration effectiveness, coupled with its robust material characteristics, makes it a preferred choice for many industries. By integrating the 1500 Diaphragm Plate into your filtration systems, you can ensure optimal performance and extend the lifespan of your equipment. Whether you are in the petrochemical industry or involved in water treatment processes, the right diaphragm plate can significantly impact your operational success.

Related News