The Essential Guide to 1000 Diaphragm Plates in Industrial Filtration

Release time:

2025-05-30

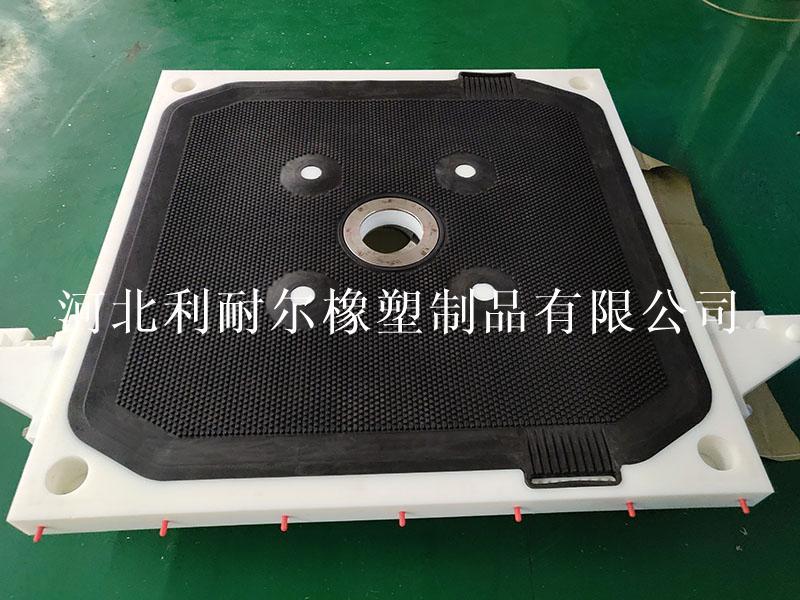

In the realm of industrial filtration, the 1000 diaphragm plate stands out as a crucial component. These plates are primarily designed to enhance the efficiency and effectiveness of various filtration systems. Understanding the role of diaphragm plates is essential for professionals seeking to optimize their filtration processes, ensuring high-quality output and operational reliability. The 1000 d

In the realm of industrial filtration, the 1000 diaphragm plate stands out as a crucial component. These plates are primarily designed to enhance the efficiency and effectiveness of various filtration systems. Understanding the role of diaphragm plates is essential for professionals seeking to optimize their filtration processes, ensuring high-quality output and operational reliability.

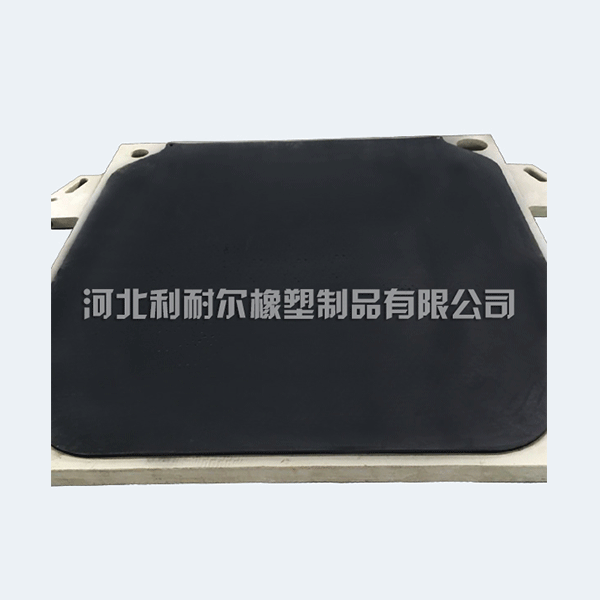

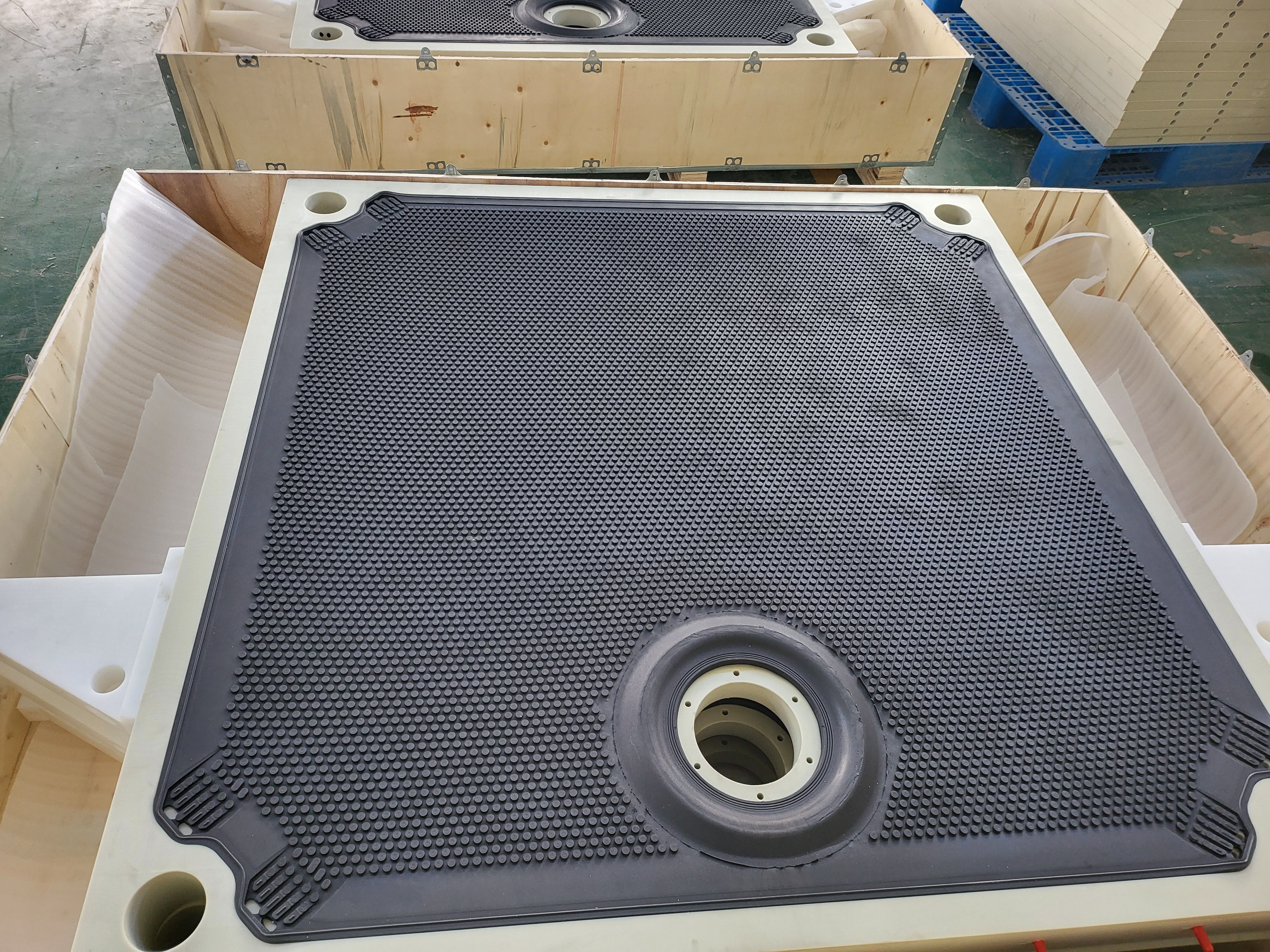

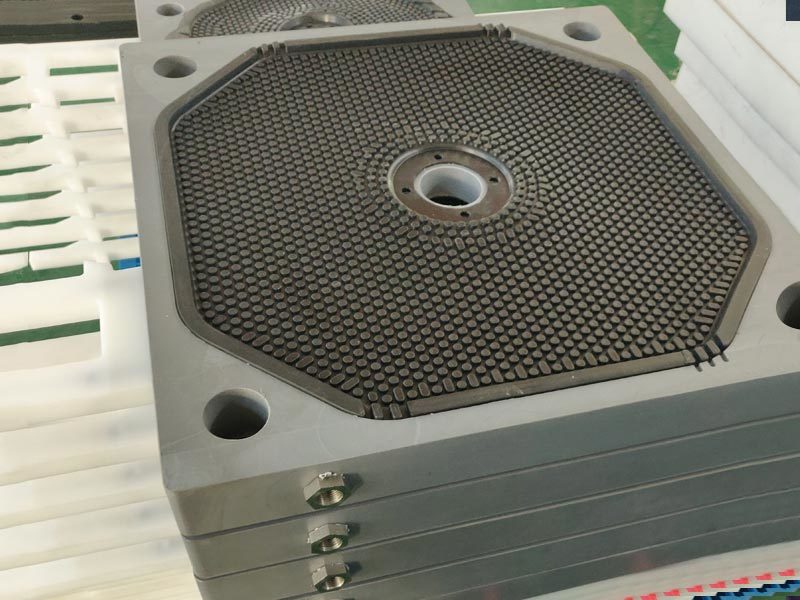

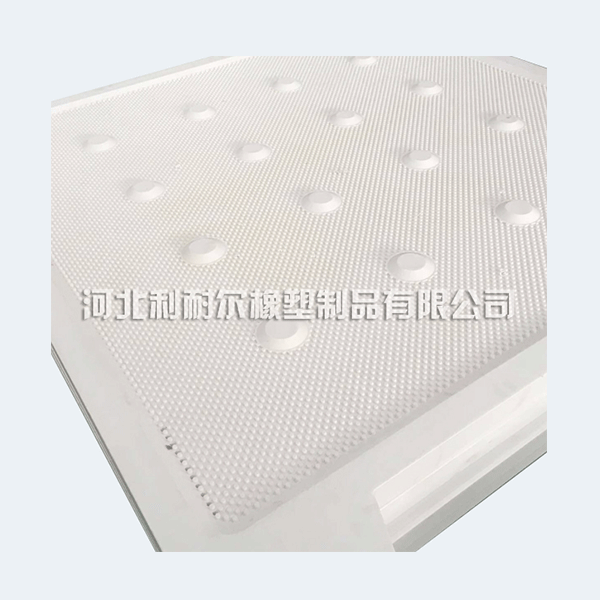

The 1000 diaphragm plate is typically utilized in applications requiring precise separation of solids from liquids or gases. Its unique design allows for excellent flexibility and durability, making it suitable for a range of industrial settings. These plates are often made from advanced materials that can withstand harsh conditions, including high temperatures and corrosive environments. This resilience is critical, especially in industries like pharmaceuticals, food processing, and chemical manufacturing, where contamination risks are high.

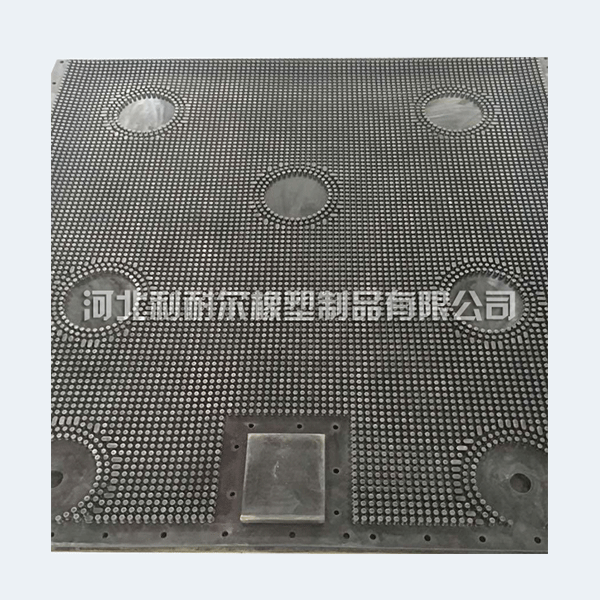

One of the primary advantages of using a diaphragm plate in filtration systems is its ability to maintain a consistent flow rate. This characteristic is especially beneficial in operations requiring continuous filtration. The design of the 1000 diaphragm plate facilitates uniform pressure distribution, which helps in minimizing wear and tear on the equipment. Consequently, this leads to reduced maintenance costs and extended lifespan of the filtration system.

Moreover, diaphragm plates are essential for achieving high levels of separation efficiency. They are engineered to optimize the filtration process by ensuring that only the desired particles pass through, while larger contaminants are effectively retained. This capability is crucial for industries that require stringent adherence to quality standards, such as water treatment facilities and petrochemical plants.

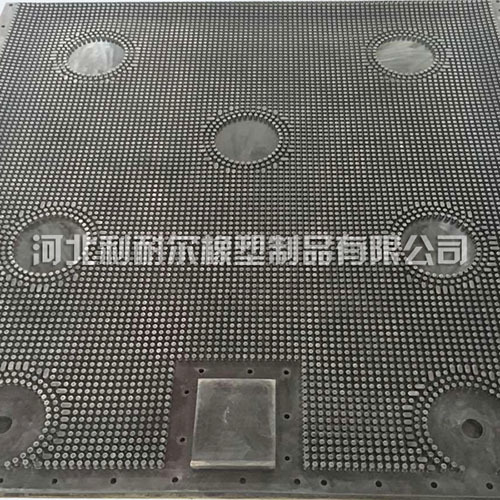

Another critical aspect of the 1000 diaphragm plate is its ease of installation and maintenance. Many designs feature user-friendly interfaces that allow for quick replacements and servicing. This not only saves time but also minimizes downtime in production processes. In industries where efficiency is paramount, having components that can be easily managed is a significant advantage.

It is also worth noting that advancements in technology have led to the development of diaphragm plates with enhanced functionalities. For instance, some modern plates are equipped with integrated sensors that monitor pressure and flow rates in real time. This innovation enables operators to make informed decisions, optimizing filtration processes and promptly addressing any issues that may arise.

In conclusion, the 1000 diaphragm plate plays a vital role in industrial filtration systems. Its durability, efficiency, and ease of maintenance make it an indispensable component for various applications. By understanding the benefits and functionalities of diaphragm plates, industry professionals can enhance their filtration processes and contribute to higher productivity and quality standards.

The 1000 diaphragm plate is typically utilized in applications requiring precise separation of solids from liquids or gases. Its unique design allows for excellent flexibility and durability, making it suitable for a range of industrial settings. These plates are often made from advanced materials that can withstand harsh conditions, including high temperatures and corrosive environments. This resilience is critical, especially in industries like pharmaceuticals, food processing, and chemical manufacturing, where contamination risks are high.

One of the primary advantages of using a diaphragm plate in filtration systems is its ability to maintain a consistent flow rate. This characteristic is especially beneficial in operations requiring continuous filtration. The design of the 1000 diaphragm plate facilitates uniform pressure distribution, which helps in minimizing wear and tear on the equipment. Consequently, this leads to reduced maintenance costs and extended lifespan of the filtration system.

Moreover, diaphragm plates are essential for achieving high levels of separation efficiency. They are engineered to optimize the filtration process by ensuring that only the desired particles pass through, while larger contaminants are effectively retained. This capability is crucial for industries that require stringent adherence to quality standards, such as water treatment facilities and petrochemical plants.

Another critical aspect of the 1000 diaphragm plate is its ease of installation and maintenance. Many designs feature user-friendly interfaces that allow for quick replacements and servicing. This not only saves time but also minimizes downtime in production processes. In industries where efficiency is paramount, having components that can be easily managed is a significant advantage.

It is also worth noting that advancements in technology have led to the development of diaphragm plates with enhanced functionalities. For instance, some modern plates are equipped with integrated sensors that monitor pressure and flow rates in real time. This innovation enables operators to make informed decisions, optimizing filtration processes and promptly addressing any issues that may arise.

In conclusion, the 1000 diaphragm plate plays a vital role in industrial filtration systems. Its durability, efficiency, and ease of maintenance make it an indispensable component for various applications. By understanding the benefits and functionalities of diaphragm plates, industry professionals can enhance their filtration processes and contribute to higher productivity and quality standards.

Related News