Release time:

2025-05-26

The Critical Role of Quality Control in 800 Diaphragm Plate Production Understanding 800 Diaphragm Plates In the world of industrial equipment, **800 diaphragm plates** play a crucial role in various applications, including filtration, separation, and pressure regulation. These plates are primarily used in systems that require precise control over fluid dynamics and pressure levels. Understanding

The Critical Role of Quality Control in 800 Diaphragm Plate Production

Understanding 800 Diaphragm Plates

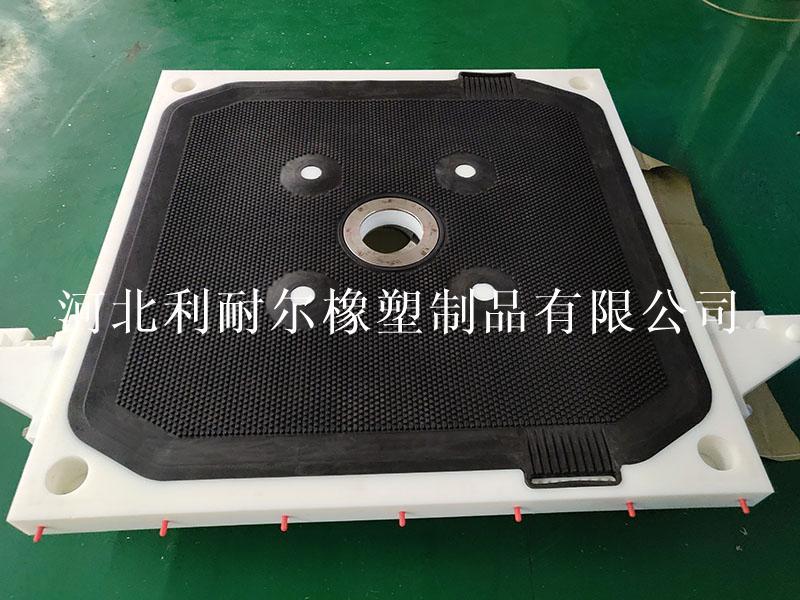

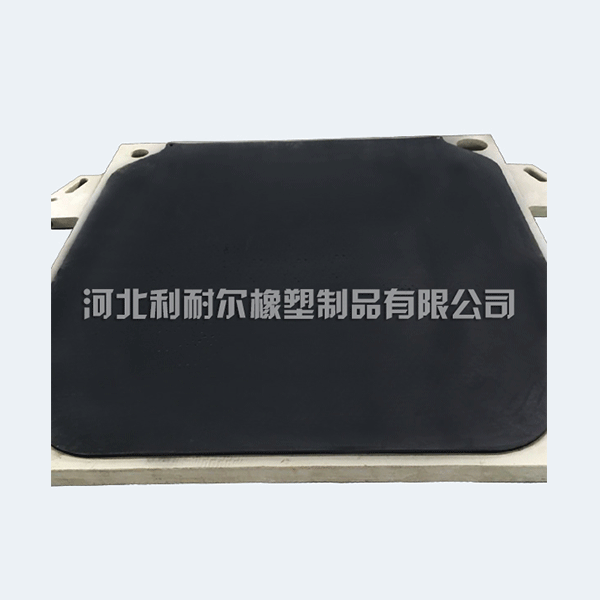

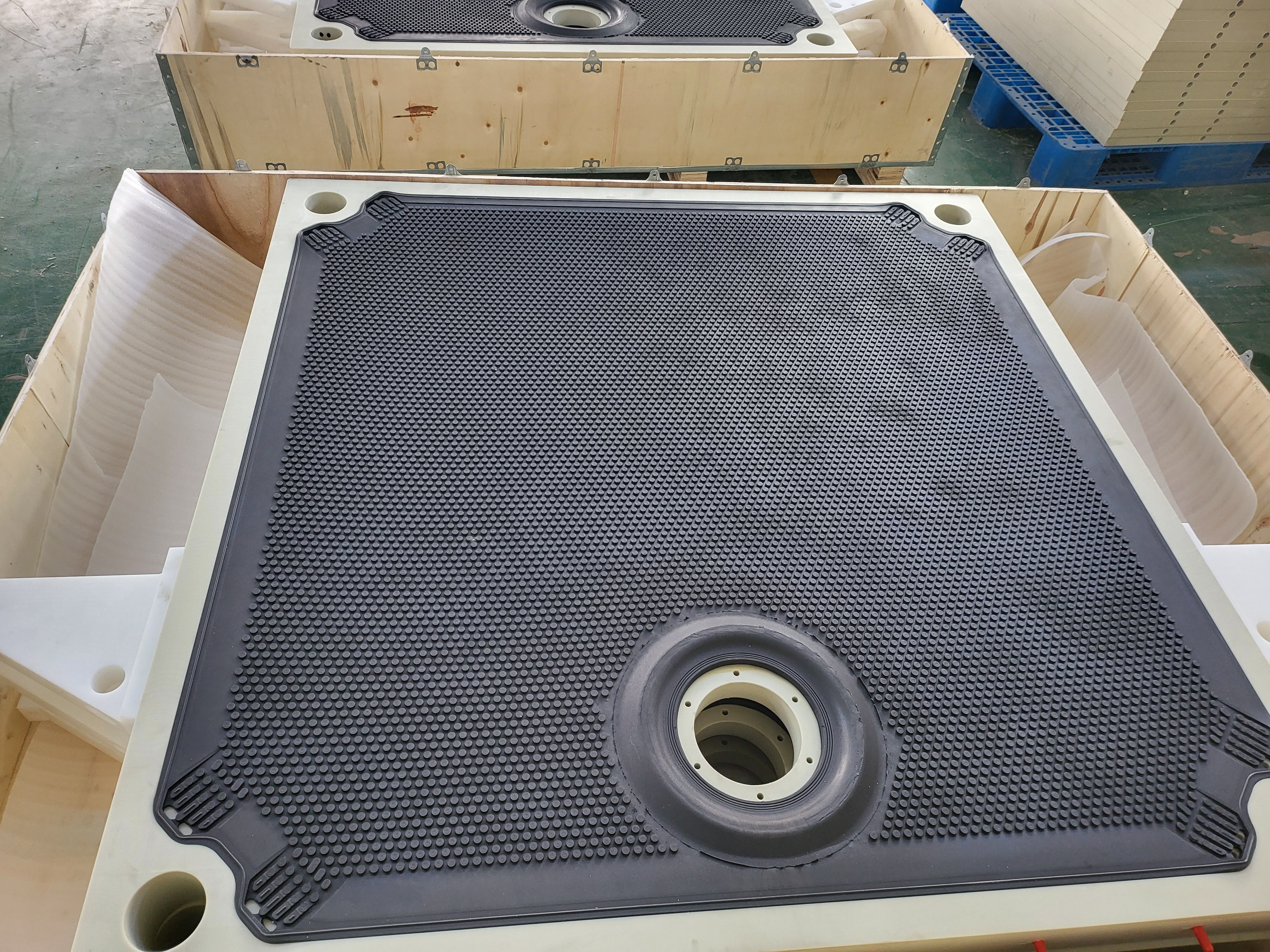

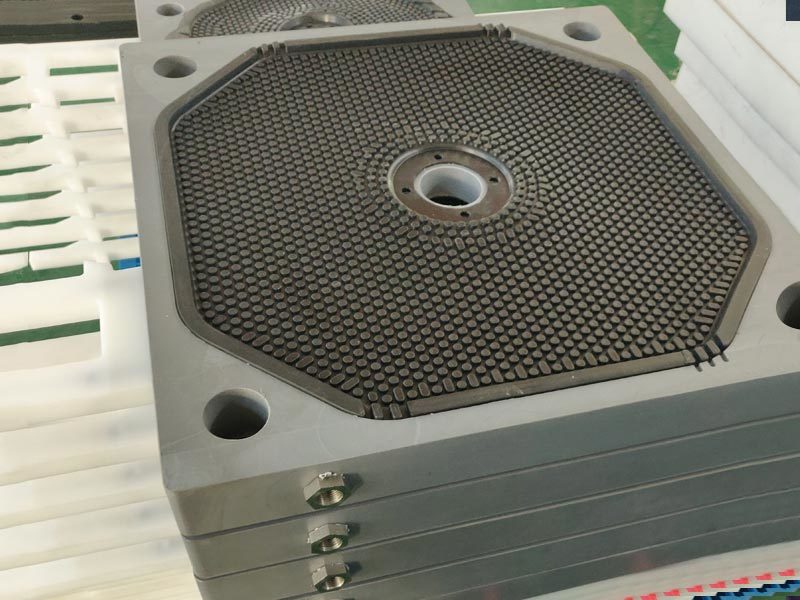

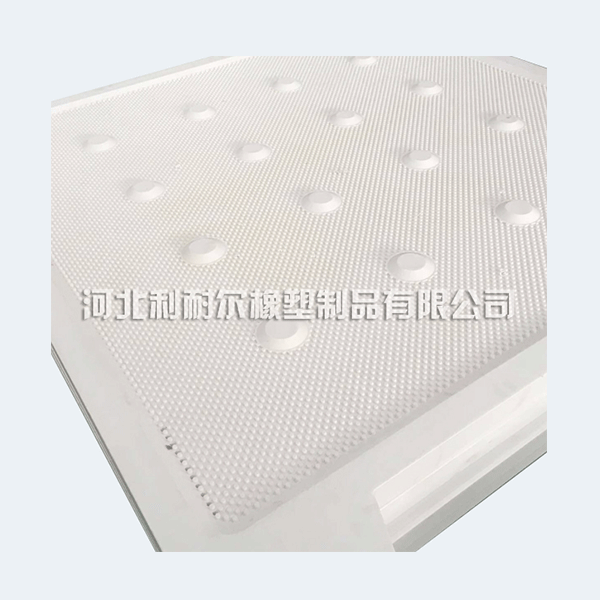

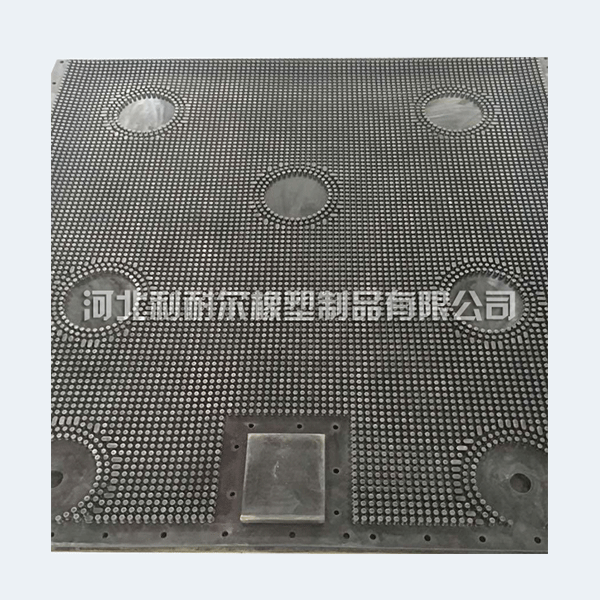

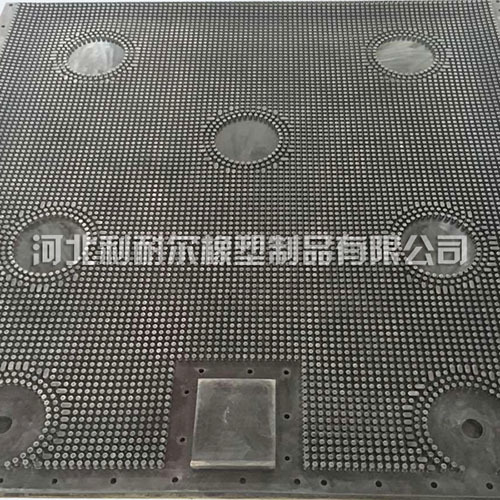

In the world of industrial equipment, **800 diaphragm plates** play a crucial role in various applications, including filtration, separation, and pressure regulation. These plates are primarily used in systems that require precise control over fluid dynamics and pressure levels. Understanding the functionality of these plates is essential to grasp the importance of quality control in their production.

What Exactly is a Diaphragm Plate?

A diaphragm plate is a flexible membrane that separates two sides of a mechanical system. In the context of filtration and industrial applications, these plates help maintain the integrity of fluid systems while allowing controlled flow. The **800 diaphragm plate** designation often indicates specific dimensions and material properties that meet particular industrial standards.

The Manufacturing Process of 800 Diaphragm Plates

The production of 800 diaphragm plates involves several stages, each requiring strict adherence to quality standards. From material selection to final testing, every step must be executed with precision to ensure the end product meets the necessary specifications. Common materials used include elastomers, metals, and engineered polymers, each requiring different handling and processing techniques.

The Importance of Quality Control in Production

Quality control (QC) is not merely an optional part of the production process; it is integral to the success and reliability of diaphragm plates. Implementing effective QC measures helps prevent defects and ensures that every plate produced meets industry specifications.

Why Quality Control Matters

The implications of inadequate quality control can be significant. Defective diaphragm plates can lead to system failures, increased downtime, and eventual financial losses. Furthermore, the reputation of a manufacturer can be severely damaged if quality issues arise in high-stakes applications. Therefore, ensuring the highest quality in production is paramount.

Key Elements of Quality Control in Diaphragm Plate Production

Quality control in the production of 800 diaphragm plates encompasses several key elements:

- Raw Material Inspection: The first step in quality control, ensuring that materials meet required specifications.

- Process Monitoring: Continuously monitoring production processes to identify deviations and rectify them promptly.

- Dimensional and Visual Inspection: Rigorously checking the dimensions and visual aspects of plates to ensure they meet design specifications.

- Functional Testing: Conducting functional tests to ensure that the diaphragm plates perform as expected under operational conditions.

- Documentation and Traceability: Keeping precise records of production batches to ensure traceability and accountability.

Implementing Effective Quality Control Measures

Successful implementation of quality control measures involves various strategies and techniques tailored to the unique requirements of diaphragm plate production.

Developing a Quality Control Plan

A robust quality control plan outlines the procedures and standards that must be followed throughout the production process. This plan serves as a guideline for all employees involved in the manufacturing of diaphragm plates.

Components of a Quality Control Plan

- Standards and Specifications: Clearly defined standards that all products must meet.

- QC Team Responsibilities: Assigning specific roles to team members to ensure accountability.

- Testing Protocols: Detailed procedures for testing and inspection at various stages of production.

- Feedback Mechanisms: Systems for collecting and analyzing feedback for continuous improvement.

Utilizing Advanced Technologies

Incorporating advanced technologies can significantly enhance the quality control process. Automated systems and AI-driven quality assessment tools can provide real-time insights into production quality, allowing for immediate adjustments when discrepancies are detected.

Challenges in Quality Control for Diaphragm Plates

While quality control is essential, it does come with its challenges. Understanding these challenges can help manufacturers devise strategies to overcome them.

Common Challenges Faced by Manufacturers

- Variability in Raw Materials: Fluctuations in raw material quality can lead to inconsistencies in final products.

- Human Error: Manual inspections and tests can be prone to errors, affecting overall quality.

- Compliance with Evolving Standards: Staying updated with industry standards can be challenging.

- Cost Constraints: Implementing rigorous quality control processes can be financially demanding.

Strategies to Mitigate Challenges

To combat these challenges, manufacturers should focus on:

- Regular Training: Providing continuous training for quality control staff to minimize human errors.

- Supplier Relationships: Building strong relationships with suppliers to ensure consistent material quality.

- Investing in Technology: Utilizing automated quality control systems to enhance accuracy and efficiency.

The Impact of Quality Control on Performance and Reliability

Quality control directly impacts the performance and reliability of 800 diaphragm plates. Ensuring that each plate meets or exceeds quality standards leads to improved efficiency, reduced maintenance costs, and enhanced customer satisfaction.

Benefits of High-Quality Diaphragm Plates

- Enhanced Durability: Quality-controlled plates are less likely to fail under pressure, extending their lifespan.

- Improved Performance: Consistent quality ensures optimal performance in various applications.

- Cost Savings: Reduced need for replacements and repairs saves money in the long run.

- Customer Trust: High-quality products build trust and loyalty among customers, promoting repeat business.

Case Studies: Quality Control in Action

Real-world examples illustrate the crucial role of quality control in diaphragm plate production. Analyzing successful case studies can provide insights into effective practices.

Case Study 1: A Leading Manufacturer's Approach

A prominent diaphragm plate manufacturer implemented a comprehensive quality control system that integrated advanced technology with traditional inspection methods. This dual approach allowed for better monitoring and reduced defects by 30% within the first year.

Case Study 2: Overcoming Challenges through Innovation

Another manufacturer faced significant challenges due to variability in raw materials. By investing in stronger supplier relationships and technology for real-time monitoring, they improved their quality control processes, leading to a 25% reduction in production costs and an increase in product reliability.

Future Trends in Quality Control for Diaphragm Plate Production

The future of quality control in diaphragm plate production is evolving with technological advancements. Emerging trends include:

Increased Automation

Automation will continue to streamline quality control processes, reducing human error and enhancing efficiency in inspections and tests.

Data Analytics and Machine Learning

Data analytics and machine learning can provide predictive insights, helping manufacturers identify potential quality issues before they arise.

Collaboration and Supply Chain Integration

Greater collaboration among suppliers, manufacturers, and customers will ensure that quality is maintained throughout the production process, from raw materials to final products.

Frequently Asked Questions (FAQs)

1. What is the significance of quality control in diaphragm plate production?

Quality control is critical to ensure that diaphragm plates meet industry specifications and perform reliably in their applications, preventing defects and enhancing customer satisfaction.

2. What are the key elements of an effective quality control plan?

An effective QC plan includes standards and specifications, responsibilities, testing protocols, and feedback mechanisms for continuous improvement.

3. How can technology improve quality control measures?

Advanced technologies, such as automated inspection systems and AI-driven analytics, enhance the accuracy and efficiency of quality control processes, enabling real-time monitoring of production quality.

4. What challenges do manufacturers face in maintaining quality control?

Common challenges include variability in raw materials, human error, compliance with evolving standards, and cost constraints.

5. How does quality control impact product performance?

Effective quality control ensures that diaphragm plates are durable and reliable, leading to improved performance, cost savings, and increased customer trust.

Conclusion

Quality control is not just a step in the production process; it is a vital component that determines the success of 800 diaphragm plate manufacturing. By implementing robust quality control measures, manufacturers can ensure that their products meet the highest standards of quality and reliability. This not only enhances customer satisfaction but also positions manufacturers for long-term success in a highly competitive industry. As technology evolves and challenges arise, continuous improvement in quality control practices will be essential for sustaining excellence in diaphragm plate production.

Related News