Essential Guide to Filter Press Accessories in the Chemical and Plastics Industry

Release time:

2025-02-23

In the chemical and plastics industry, filter presses play a vital role in separating solids from liquids, ensuring product purity and process efficiency. To maximize the performance of these machines, it is important to consider the various filter press accessories that can enhance their functionality. These accessories not only improve filtration efficiency but also contribute to overall operati

In the chemical and plastics industry, filter presses play a vital role in separating solids from liquids, ensuring product purity and process efficiency. To maximize the performance of these machines, it is important to consider the various filter press accessories that can enhance their functionality. These accessories not only improve filtration efficiency but also contribute to overall operational effectiveness.

One of the most common accessories for filter presses is the filter cloth. The choice of filter cloth depends on the specific application and the nature of the slurry being processed. Different materials, weaves, and coatings are available, allowing for optimized filtration rates and cake release. Utilizing the right filter cloth can significantly reduce downtime and improve the quality of the final product.

Another critical accessory is the hydraulic system, which is responsible for the operation of the filter press. A reliable hydraulic unit ensures consistent pressure during the filtration process, which is essential for achieving the desired results. Regular maintenance of the hydraulic components is necessary to prevent leaks and ensure smooth operation. Investing in a high-quality hydraulic system can lead to enhanced performance and longevity of the filter press.

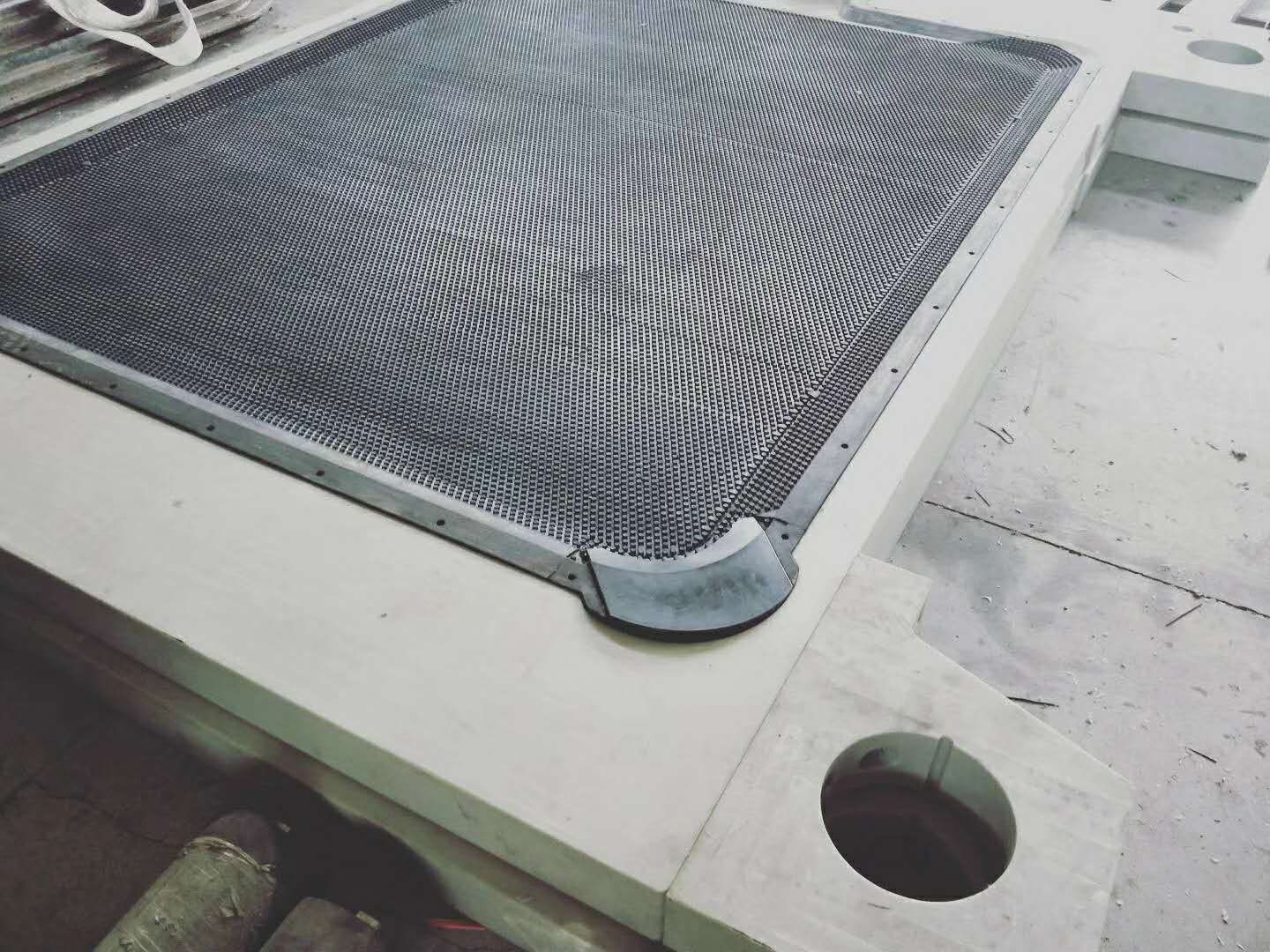

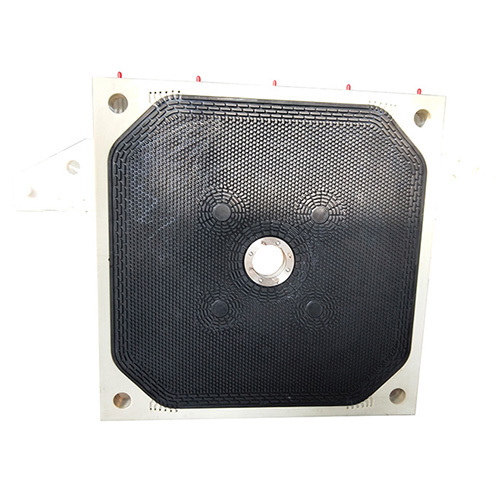

In addition to these components, filter press frames and plates are essential accessories that should not be overlooked. The design and material of the plates can influence the amount of cake produced and the ease of cleaning. Choosing corrosion-resistant materials is particularly important in chemical applications, where exposure to harsh substances is common. Additionally, the configuration of the frame can facilitate easier handling and maintenance.

Chemical dosing systems are also valuable accessories that aid in optimizing the filtration process. These systems allow for the precise addition of flocculants or coagulants, which help in agglomerating particles for more efficient solid-liquid separation. By automating the dosing process, you can achieve better consistency and accuracy, ultimately improving the overall efficiency of the filter press operation.

Finally, monitoring and control systems are essential for modern filter presses. These systems provide real-time data on pressure, flow rates, and cake thickness, enabling operators to make informed decisions and adjustments during the filtration process. By implementing advanced monitoring technology, companies can enhance operational efficiency and minimize the risk of equipment failure.

In conclusion, investing in the right filter press accessories is crucial for optimizing filtration processes in the chemical and plastics industry. From selecting the appropriate filter cloth to incorporating advanced monitoring systems, each accessory plays a significant role in achieving operational excellence. Understanding these components will not only improve filtration efficiency but also enhance product quality, making it a worthwhile focus for businesses looking to advance their filtration capabilities.

One of the most common accessories for filter presses is the filter cloth. The choice of filter cloth depends on the specific application and the nature of the slurry being processed. Different materials, weaves, and coatings are available, allowing for optimized filtration rates and cake release. Utilizing the right filter cloth can significantly reduce downtime and improve the quality of the final product.

Another critical accessory is the hydraulic system, which is responsible for the operation of the filter press. A reliable hydraulic unit ensures consistent pressure during the filtration process, which is essential for achieving the desired results. Regular maintenance of the hydraulic components is necessary to prevent leaks and ensure smooth operation. Investing in a high-quality hydraulic system can lead to enhanced performance and longevity of the filter press.

In addition to these components, filter press frames and plates are essential accessories that should not be overlooked. The design and material of the plates can influence the amount of cake produced and the ease of cleaning. Choosing corrosion-resistant materials is particularly important in chemical applications, where exposure to harsh substances is common. Additionally, the configuration of the frame can facilitate easier handling and maintenance.

Chemical dosing systems are also valuable accessories that aid in optimizing the filtration process. These systems allow for the precise addition of flocculants or coagulants, which help in agglomerating particles for more efficient solid-liquid separation. By automating the dosing process, you can achieve better consistency and accuracy, ultimately improving the overall efficiency of the filter press operation.

Finally, monitoring and control systems are essential for modern filter presses. These systems provide real-time data on pressure, flow rates, and cake thickness, enabling operators to make informed decisions and adjustments during the filtration process. By implementing advanced monitoring technology, companies can enhance operational efficiency and minimize the risk of equipment failure.

In conclusion, investing in the right filter press accessories is crucial for optimizing filtration processes in the chemical and plastics industry. From selecting the appropriate filter cloth to incorporating advanced monitoring systems, each accessory plays a significant role in achieving operational excellence. Understanding these components will not only improve filtration efficiency but also enhance product quality, making it a worthwhile focus for businesses looking to advance their filtration capabilities.

Related News