Exploring the Benefits of Using 880 Filter Plates in Industrial Filtration

Release time:

2025-01-10

Exploring the Benefits of Using 880 Filter Plates in Industrial Filtration Table of Contents 1. Introduction to 880 Filter Plates 2. Design and Technology Behind 880 Filter Plates 3. Key Applications of 880 Filter Plates in Different Industries 4. Advantages of Using 880 Filter Plates in Industrial Filtration 5. Maintenance Tips for 880 Filter Plates 6. Comparing 880 Filte

Exploring the Benefits of Using 880 Filter Plates in Industrial Filtration

Table of Contents

- 1. Introduction to 880 Filter Plates

- 2. Design and Technology Behind 880 Filter Plates

- 3. Key Applications of 880 Filter Plates in Different Industries

- 4. Advantages of Using 880 Filter Plates in Industrial Filtration

- 5. Maintenance Tips for 880 Filter Plates

- 6. Comparing 880 Filter Plates with Other Filtration Solutions

- 7. Real-World Case Studies Using 880 Filter Plates

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to 880 Filter Plates

In the world of industrial filtration, **880 Filter Plates** stand out as an innovative solution designed to enhance efficiency and effectiveness across various applications. These plates are pivotal in separating solids from liquids, thereby improving the quality of the output in numerous industrial processes. Understanding the benefits and functionalities of **880 Filter Plates** is crucial for industries aiming to optimize their filtration systems.

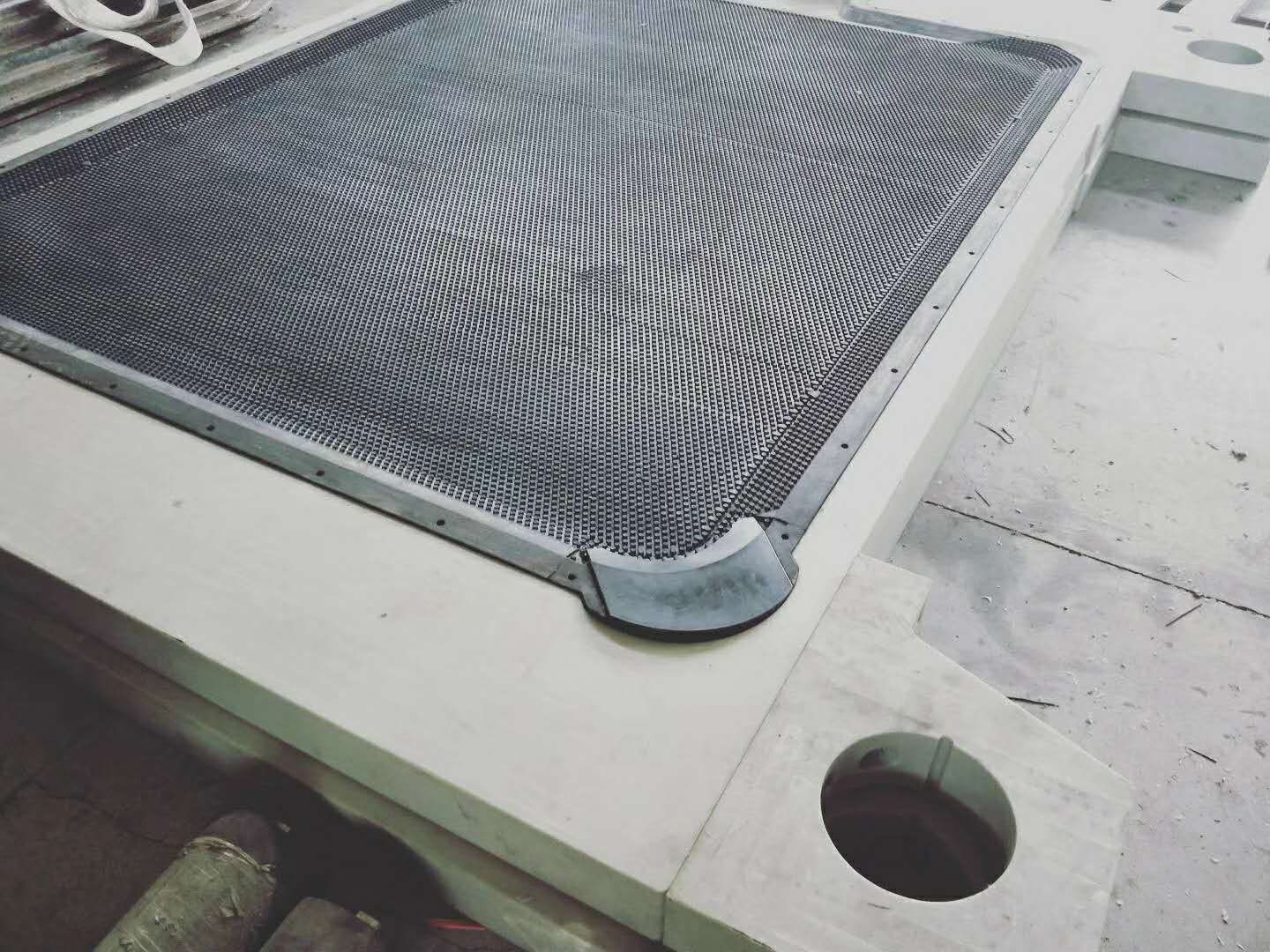

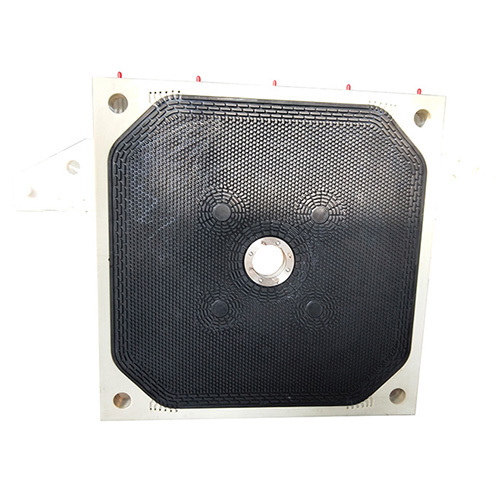

2. Design and Technology Behind 880 Filter Plates

The design of **880 Filter Plates** incorporates advanced engineering principles that maximize performance. Typically made from durable materials, these plates feature a unique configuration that allows for **improved flow rates** and **reduced pressure drops**. The geometry of the plates aids in the **efficient removal of contaminants**, which is vital for maintaining product quality.

The technology behind these filter plates includes innovative **surface treatments** that further enhance their effectiveness. The materials used are resistant to corrosion, ensuring longevity even in harsh operating environments. This durability is essential for industries that rely on continuous operation without frequent downtimes for maintenance.

3. Key Applications of 880 Filter Plates in Different Industries

**880 Filter Plates** find applications across various sectors, demonstrating their versatility. Here are some key industries utilizing these plates:

3.1 Pharmaceutical Industry

In the pharmaceutical sector, maintaining the purity of products is critical. **880 Filter Plates** are used to ensure that contaminants are effectively removed from liquid medications, thereby adhering to strict regulatory standards.

3.2 Food and Beverage Industry

The food and beverage sector relies on **880 Filter Plates** to maintain clarity and quality in beverages, oils, and other liquid products. Their ability to filter out particulates ensures that the end products are safe for consumption.

3.3 Chemical Manufacturing

In chemical manufacturing, these filter plates help in the separation of solids from liquids, which is essential in processes such as **reactor effluent filtration** and **product purification**.

3.4 Water Treatment Facilities

Water treatment facilities utilize **880 Filter Plates** to remove sediments and other impurities from water, ensuring that the final product meets health and safety standards.

4. Advantages of Using 880 Filter Plates in Industrial Filtration

The advantages of incorporating **880 Filter Plates** into industrial filtration systems are numerous:

4.1 Enhanced Filtration Efficiency

The unique design of these plates allows for superior filtration performance, capturing even the finest particles while maintaining high flow rates.

4.2 Cost-Effectiveness

Although the initial investment in **880 Filter Plates** may be higher than alternative solutions, their durability and efficiency lead to lower operational costs over time. Industries benefit from reduced downtime and maintenance expenses.

4.3 Environmental Benefits

By optimizing filtration processes, **880 Filter Plates** contribute to a cleaner environment. Efficient filtration reduces waste and minimizes the release of contaminants into the ecosystem.

4.4 Flexibility and Customization

**880 Filter Plates** can be tailored to meet the specific needs of different industries. This customization ensures that companies can achieve optimal performance based on their unique filtration requirements.

5. Maintenance Tips for 880 Filter Plates

Proper maintenance of **880 Filter Plates** is essential to ensure their longevity and performance. Here are some maintenance tips:

5.1 Regular Inspections

Conduct routine inspections to identify any signs of wear or damage. Early detection of issues can prevent larger problems down the line.

5.2 Cleaning Protocols

Establish a cleaning schedule to remove any accumulated solids on the filter plates. This will ensure that the plates remain effective and reduce the risk of clogging.

5.3 Replacement Schedule

Develop a replacement schedule based on the usage and conditions of the filtration system. Regular replacements will help maintain optimal performance.

6. Comparing 880 Filter Plates with Other Filtration Solutions

When considering filtration solutions, it is important to compare **880 Filter Plates** with alternatives:

6.1 Membrane Filters vs. 880 Filter Plates

Membrane filters offer fine filtration but may have higher operational costs and require more frequent replacements. In contrast, **880 Filter Plates** provide a balance of performance and cost-efficiency.

6.2 Bag Filters vs. 880 Filter Plates

While bag filters are simple and effective, they often need more frequent changing. **880 Filter Plates** can offer higher filtration efficiency and longevity.

7. Real-World Case Studies Using 880 Filter Plates

To understand the practical benefits of **880 Filter Plates**, we can look at several case studies:

7.1 Case Study: Pharmaceutical Filtration

A leading pharmaceutical company implemented **880 Filter Plates** in their production lines, resulting in a 30% reduction in contamination incidents. The enhanced filtration capability improved the overall quality of their products.

7.2 Case Study: Beverage Processing

A beverage manufacturer reported a significant increase in production efficiency after switching to **880 Filter Plates**. The plates allowed for faster processing times while maintaining the clarity and safety of their products.

8. Frequently Asked Questions

8.1 What materials are 880 Filter Plates made from?

**880 Filter Plates** are typically constructed from durable, corrosion-resistant materials, which ensures longevity and reliability in various industrial applications.

8.2 How do I choose the right size of 880 Filter Plates?

Choosing the right size depends on your specific filtration needs and the scale of your operation. Consulting with a filtration expert can help you make an informed decision.

8.3 How often do 880 Filter Plates need to be replaced?

The replacement frequency varies based on usage and the nature of the materials being filtered. Regular inspections can help determine the optimal replacement schedule.

8.4 Can 880 Filter Plates be customized for specific applications?

Yes, **880 Filter Plates** can be customized to meet specific filtration requirements, ensuring optimal performance for different industries.

8.5 What are the environmental benefits of using 880 Filter Plates?

Using **880 Filter Plates** can lead to reduced waste and lower emissions, contributing to a cleaner environment and sustainable industrial practices.

9. Conclusion

In the ever-evolving landscape of industrial filtration, **880 Filter Plates** offer a multitude of benefits that can significantly enhance operational efficiency and product quality. Their advanced design, versatility in application, and cost-effectiveness make them an invaluable asset for industries ranging from pharmaceuticals to water treatment. By understanding their functionalities and advantages, companies can make informed decisions that optimize their filtration processes, ultimately leading to improved productivity and sustainability. Embracing **880 Filter Plates** is not just a choice; it’s a strategic move towards achieving excellence in industrial filtration systems.

Related News