Maximizing Filtration Efficiency: The Importance of a 1200 Diaphragm Plate

Release time:

2025-05-18

Maximizing Filtration Efficiency: The Importance of a 1200 Diaphragm Plate Table of Contents Understanding Diaphragm Plates What is a 1200 Diaphragm Plate? The Role of Diaphragm Plates in Industrial Filtration Benefits of Using a 1200 Diaphragm Plate Key Features of the 1200 Diaphragm Plate Installation and Maintenance Best Practices Common Applications of 1200 Diaphra

Maximizing Filtration Efficiency: The Importance of a 1200 Diaphragm Plate

Table of Contents

- Understanding Diaphragm Plates

- What is a 1200 Diaphragm Plate?

- The Role of Diaphragm Plates in Industrial Filtration

- Benefits of Using a 1200 Diaphragm Plate

- Key Features of the 1200 Diaphragm Plate

- Installation and Maintenance Best Practices

- Common Applications of 1200 Diaphragm Plates

- Troubleshooting Common Issues

- Conclusion

- FAQs

Understanding Diaphragm Plates

Diaphragm plates are essential components in various filtration systems, primarily used in industries such as water treatment, chemical processing, and pharmaceuticals. Their primary role is to provide a barrier that separates solids from liquids while allowing for efficient flow. These plates are designed to withstand high pressures and are often made from robust materials that ensure longevity and durability.

What is a 1200 Diaphragm Plate?

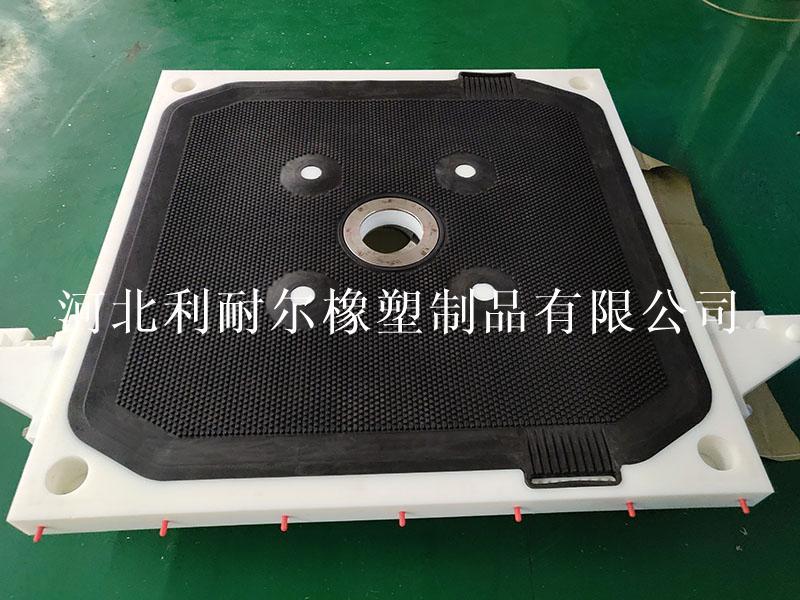

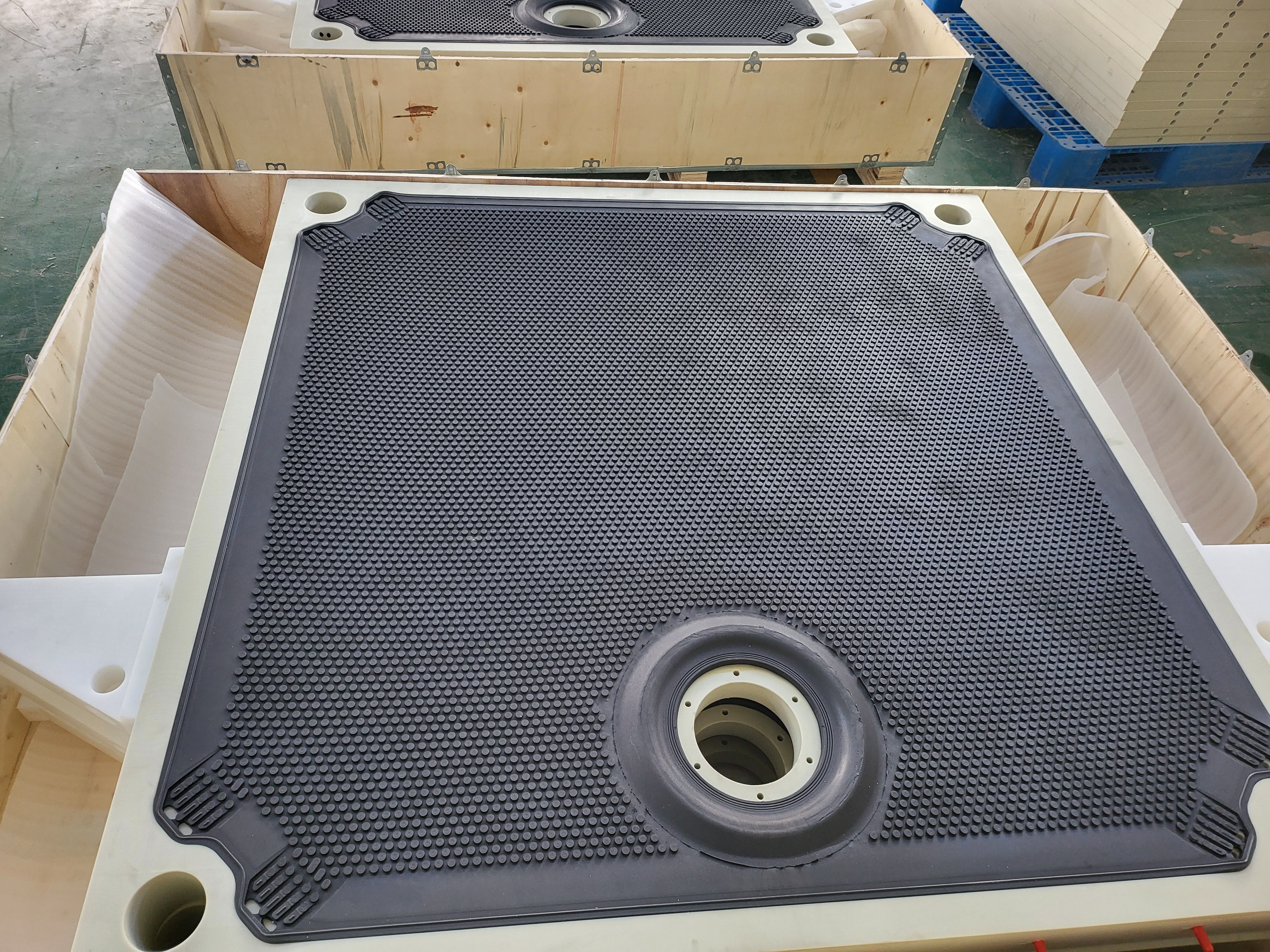

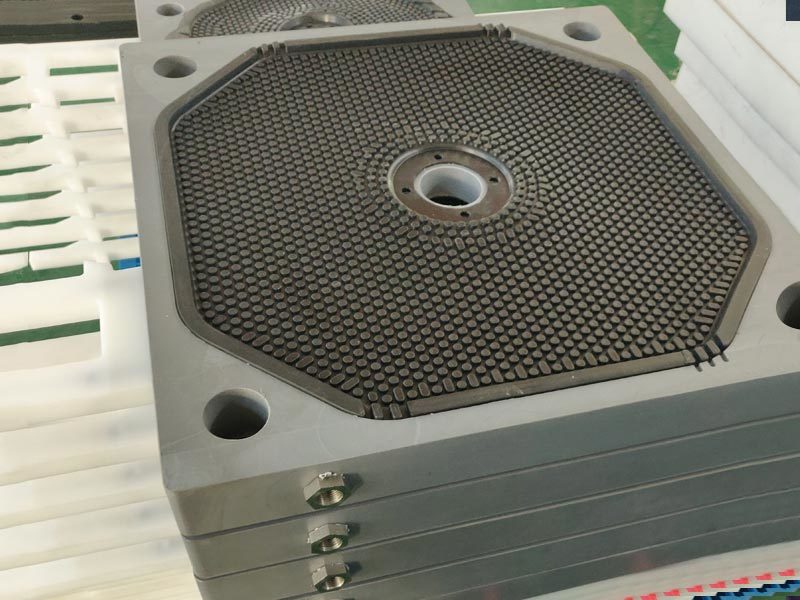

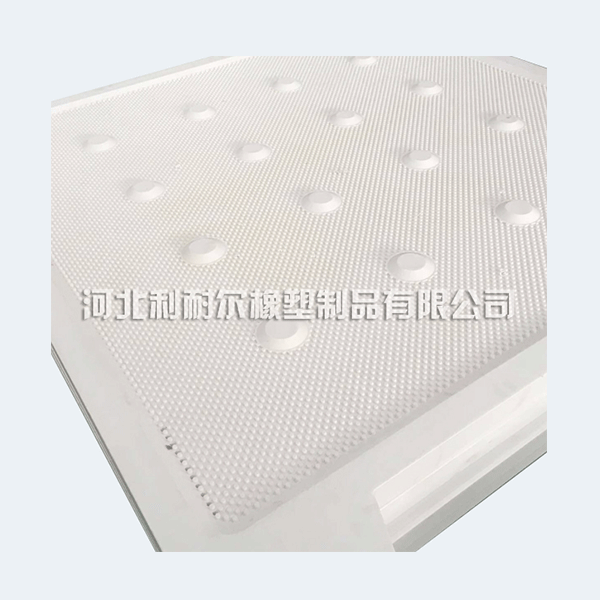

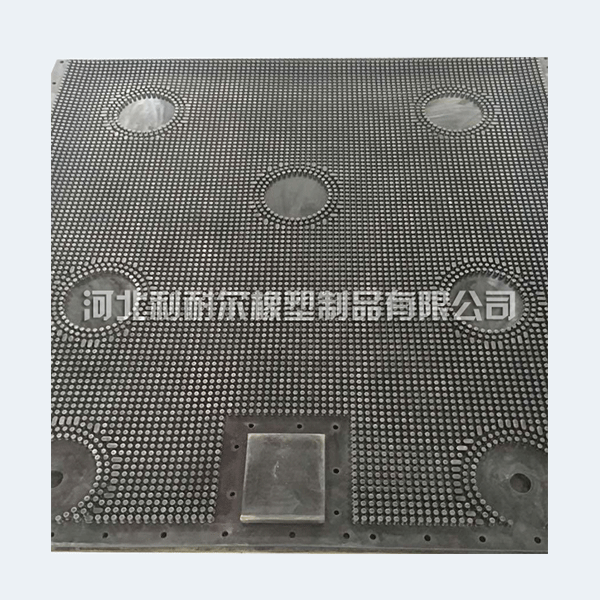

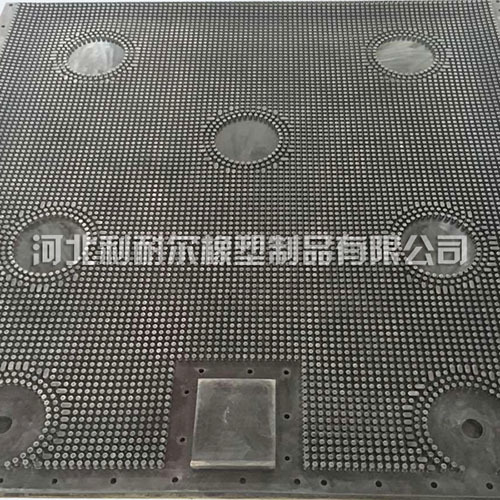

The 1200 diaphragm plate refers to a specific type of diaphragm plate that measures 1200 millimeters in diameter. This size is particularly advantageous for large-scale industrial applications where high filtration efficiency is a priority. The design of the 1200 diaphragm plate allows for optimal performance in separating solids from liquids, making it a preferred choice among manufacturers and operators.

The Role of Diaphragm Plates in Industrial Filtration

Diaphragm plates play a critical role in enhancing the overall filtration efficiency of industrial systems. They help to minimize the risk of clogging and ensure consistent performance, which is vital for maintaining product quality and compliance with industry regulations. The efficient separation of solids from liquids not only leads to cleaner products but also reduces waste and lowers operational costs.

Benefits of Using a 1200 Diaphragm Plate

When considering the implementation of a 1200 diaphragm plate, a range of benefits becomes evident:

1. Enhanced Filtration Efficiency

The 1200 diaphragm plate is designed to maximize filtration efficiency, allowing for superior separation of solids from liquids. This results in cleaner effluent and higher-quality end products.

2. Increased Throughput

Due to its larger diameter, the 1200 diaphragm plate can accommodate a higher volume of liquid, leading to increased throughput in industrial processes. This efficiency translates to faster production times and improved operational efficiency.

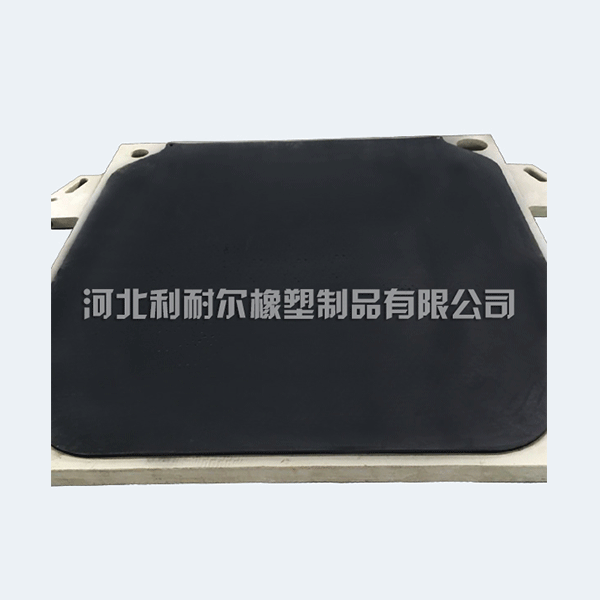

3. Durability and Longevity

Constructed from high-quality materials, the 1200 diaphragm plates are built to last. Their resistance to corrosion and wear ensures that they maintain performance over an extended period, reducing the need for frequent replacements.

4. Cost-Effectiveness

Investing in a 1200 diaphragm plate may lead to significant cost savings. By improving efficiency and reducing operational downtime, these plates can lower the overall cost of filtration processes.

Key Features of the 1200 Diaphragm Plate

Understanding the key features of the 1200 diaphragm plate can further highlight its benefits:

1. Compatibility with Various Liquids

The design and materials used in the construction of the 1200 diaphragm plate allow it to handle a wide range of liquids, including corrosive and abrasive substances.

2. Optimized Flow Design

The flow design of the 1200 diaphragm plate is engineered to minimize turbulence and maximize flow rates, enhancing the overall filtration process.

3. Easy Installation and Maintenance

With user-friendly installation procedures and minimal maintenance requirements, the 1200 diaphragm plate offers convenience and efficiency for operators.

Installation and Maintenance Best Practices

To ensure the longevity and effectiveness of the 1200 diaphragm plate, adhering to best practices for installation and maintenance is crucial.

1. Proper Alignment and Sealing

During installation, ensure that the diaphragm plate is properly aligned and sealed to prevent any leakage, which can compromise filtration efficiency.

2. Routine Inspections

Regularly inspect the diaphragm plate for signs of wear or damage. Early detection of issues can prevent larger problems down the line and reduce maintenance costs.

3. Cleaning Protocols

Establish a cleaning protocol that suits the specific applications of your filtration system. This ensures that the diaphragm plate operates at peak efficiency over its lifespan.

Common Applications of 1200 Diaphragm Plates

The versatility of the 1200 diaphragm plate allows it to be utilized in various industrial applications, including:

1. Wastewater Treatment

In wastewater treatment facilities, the 1200 diaphragm plate efficiently separates solids from effluent, ensuring compliance with environmental regulations.

2. Chemical Processing

The chemical industry benefits from the robust design of the 1200 diaphragm plate, as it can handle corrosive materials while maintaining high filtration performance.

3. Food and Beverage Industry

In the food and beverage sector, these diaphragm plates ensure that products meet quality standards by removing unwanted solids from liquids without compromising the integrity of the product.

Troubleshooting Common Issues

Even with the best designs, issues can arise. Here are some common problems associated with diaphragm plates and how to troubleshoot them:

1. Clogging

If clogging occurs, it may be due to inadequate cleaning or improper material selection. Regular maintenance and appropriate pre-filtration can mitigate this issue.

2. Leaks

Leaks can stem from poor installation or wear and tear. Regularly check seals and joints, and replace any damaged components promptly.

3. Reduced Flow Rate

A decrease in flow rate may indicate a blockage or damage to the diaphragm plate. Performing routine inspections can help identify and rectify issues early.

Conclusion

In conclusion, the **1200 diaphragm plate** is an invaluable component in maximizing filtration efficiency across various industrial applications. Its enhanced filtration capabilities, durability, and cost-effectiveness make it the ideal choice for operators looking to improve their processes. By understanding how to properly implement and maintain these plates, industries can ensure optimal performance and longevity, leading to cleaner products and reduced operational costs.

FAQs

1. What is the lifespan of a 1200 diaphragm plate?

The lifespan can vary depending on the materials used, the environment, and the frequency of maintenance. However, with proper care, these plates can last for several years.

2. Can a 1200 diaphragm plate be used with all types of liquids?

While the 1200 diaphragm plate is versatile, it's essential to choose materials compatible with the specific chemicals or substances you'll be filtering.

3. How often should I inspect my diaphragm plate?

Routine inspections should be conducted at regular intervals, ideally every few months, or more frequently if the system processes high volumes or abrasive materials.

4. What are the signs that my diaphragm plate needs replacing?

Look for signs of wear, corrosion, leaks, or significant performance drops in filtration efficiency. If any of these issues arise, it may be time for a replacement.

5. Are there any specific cleaning methods recommended for diaphragm plates?

Cleaning methods depend on the materials being filtered. Always refer to the manufacturer’s guidelines for the best cleaning practices to avoid damaging the plate.

Related News