Essential Insights into Filter Press Accessories in the Chemical and Plastics Industry

Release time:

2025-05-14

Filter presses are vital in the chemical and plastics industry for solid-liquid separation processes. While the main component is the filter press itself, the accessories accompanying it play a crucial role in optimizing performance, enhancing functionality, and ensuring operational efficiency. Understanding filter press accessories is essential for industry professionals aiming to maximize their

Filter presses are vital in the chemical and plastics industry for solid-liquid separation processes. While the main component is the filter press itself, the accessories accompanying it play a crucial role in optimizing performance, enhancing functionality, and ensuring operational efficiency. Understanding filter press accessories is essential for industry professionals aiming to maximize their systems.

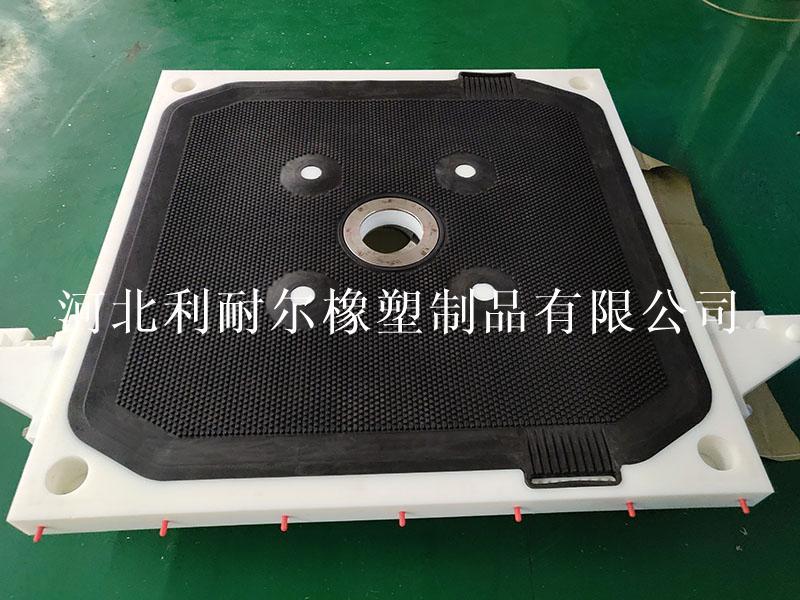

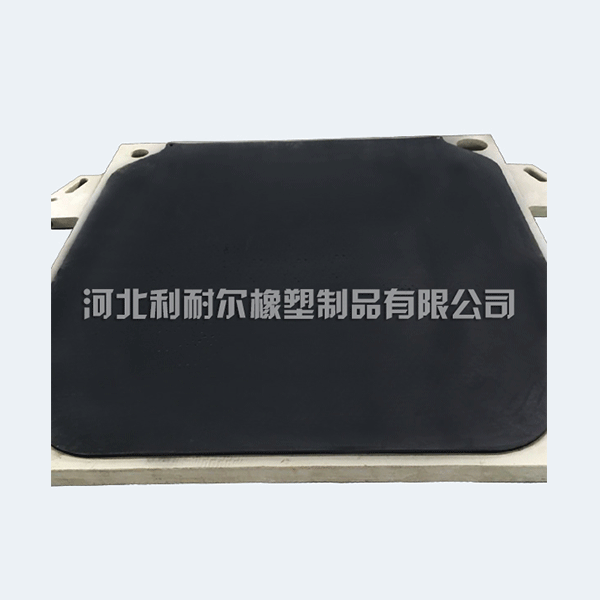

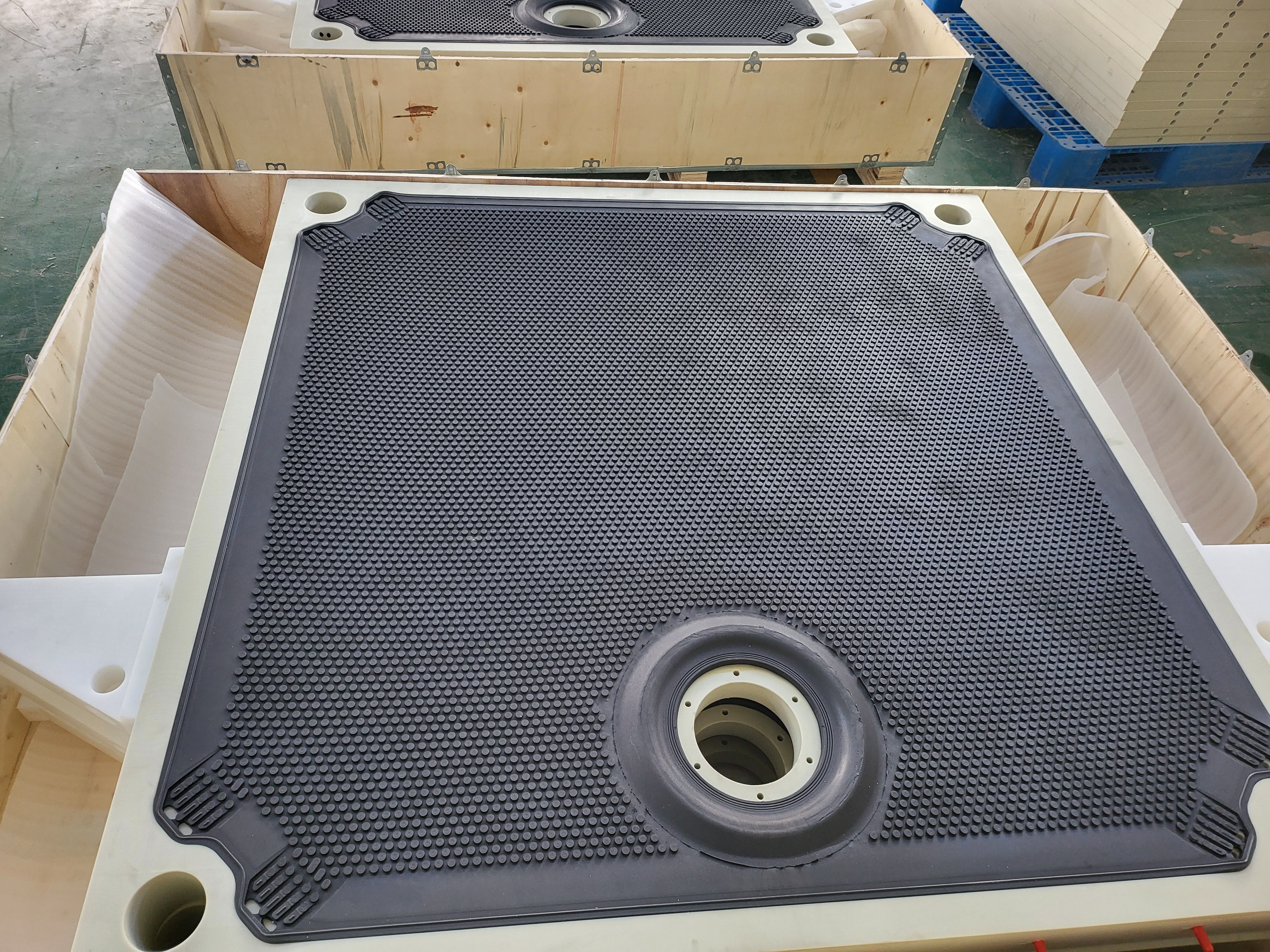

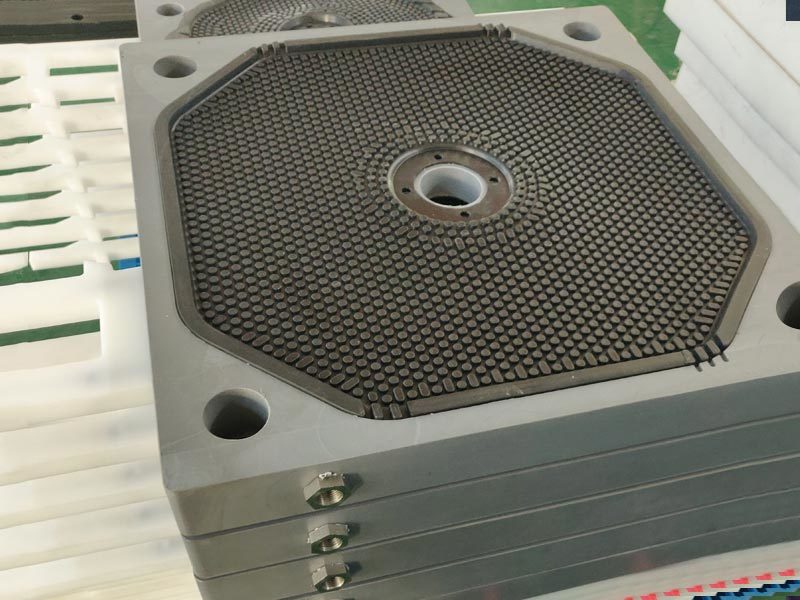

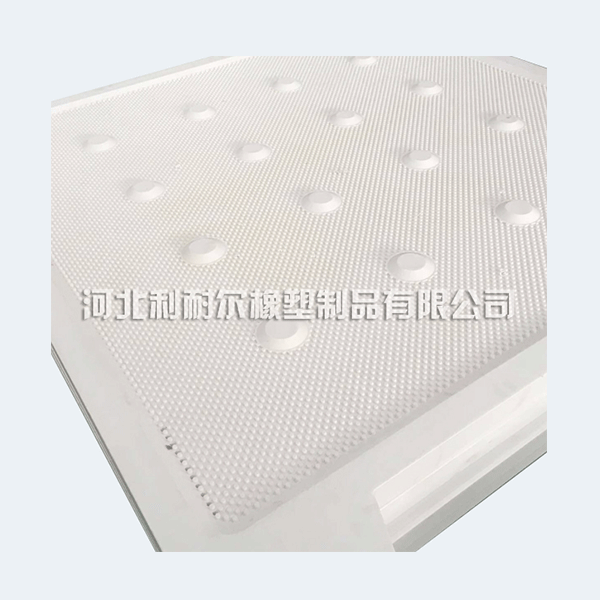

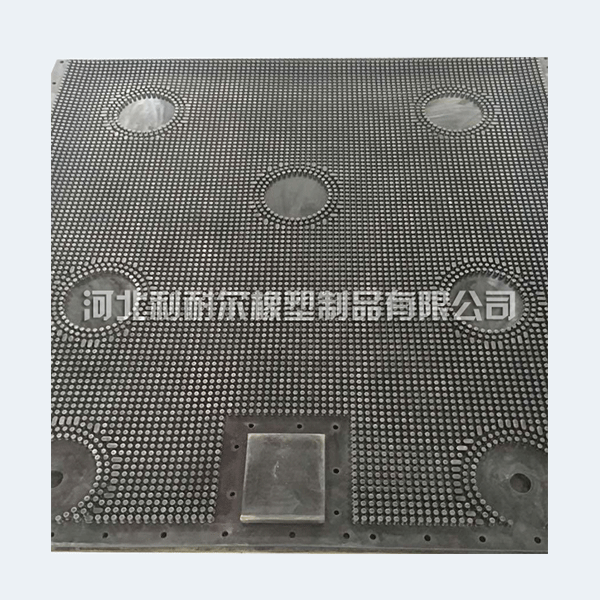

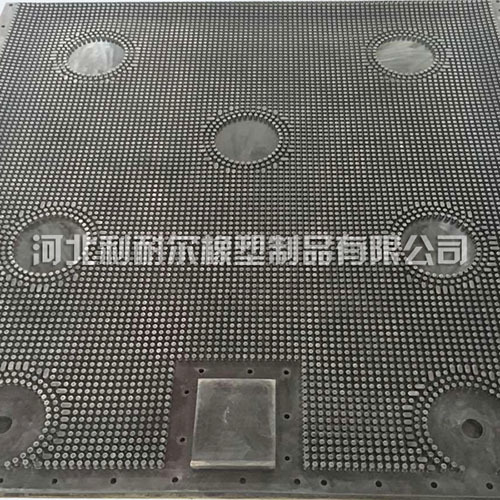

One of the primary accessories is the filter cloth. It acts as a barrier, allowing liquid to pass while retaining solid particles. The choice of filter cloth material, thickness, and weave pattern can significantly influence the clarity of the filtrate and the overall efficiency of the separation process. Professionals should consider the nature of the materials being filtered, temperature resistance, and chemical compatibility when selecting filter cloths.

Another vital accessory is the hydraulic system. Filter presses operate under pressure, and a reliable hydraulic system ensures that the plates are correctly compressed to achieve optimal filtration. Moreover, it allows for automatic plate shifting, enhancing the automation of the process. Regular maintenance of this system is crucial for preventing leaks and ensuring consistent operation.

Additionally, the discharge system, which includes pumps and valves, is essential for the effective removal of the filtrate and the cake formed during the filtration process. A well-designed discharge system can reduce downtime and enhance productivity. For instance, pneumatic or diaphragm pumps can be utilized to facilitate the transfer of slurry and ensure that the process remains uninterrupted.

Monitoring devices, including pressure gauges and flow meters, are also critical accessories. These devices provide real-time data on the operation of the filter press, allowing operators to identify potential issues before they escalate. Implementing a routine maintenance schedule for these monitoring systems can significantly improve the reliability of the entire filtration system.

Another important aspect of filter press accessories is the filter cake handling equipment. This includes conveyors and hoppers designed for the efficient transportation and disposal of the solid cake formed after filtration. Proper handling of the filter cake is essential, not only for operational efficiency but also for compliance with environmental regulations.

In summary, filter press accessories play an integral role in enhancing the efficiency and effectiveness of separation processes within the chemical and plastics industry. By paying close attention to the selection and maintenance of these accessories, industry professionals can significantly improve their filtration operations, reduce costs, and ensure a smoother workflow. Understanding the importance of each accessory can lead to more informed decisions, resulting in better performance and outcomes in various applications.

One of the primary accessories is the filter cloth. It acts as a barrier, allowing liquid to pass while retaining solid particles. The choice of filter cloth material, thickness, and weave pattern can significantly influence the clarity of the filtrate and the overall efficiency of the separation process. Professionals should consider the nature of the materials being filtered, temperature resistance, and chemical compatibility when selecting filter cloths.

Another vital accessory is the hydraulic system. Filter presses operate under pressure, and a reliable hydraulic system ensures that the plates are correctly compressed to achieve optimal filtration. Moreover, it allows for automatic plate shifting, enhancing the automation of the process. Regular maintenance of this system is crucial for preventing leaks and ensuring consistent operation.

Additionally, the discharge system, which includes pumps and valves, is essential for the effective removal of the filtrate and the cake formed during the filtration process. A well-designed discharge system can reduce downtime and enhance productivity. For instance, pneumatic or diaphragm pumps can be utilized to facilitate the transfer of slurry and ensure that the process remains uninterrupted.

Monitoring devices, including pressure gauges and flow meters, are also critical accessories. These devices provide real-time data on the operation of the filter press, allowing operators to identify potential issues before they escalate. Implementing a routine maintenance schedule for these monitoring systems can significantly improve the reliability of the entire filtration system.

Another important aspect of filter press accessories is the filter cake handling equipment. This includes conveyors and hoppers designed for the efficient transportation and disposal of the solid cake formed after filtration. Proper handling of the filter cake is essential, not only for operational efficiency but also for compliance with environmental regulations.

In summary, filter press accessories play an integral role in enhancing the efficiency and effectiveness of separation processes within the chemical and plastics industry. By paying close attention to the selection and maintenance of these accessories, industry professionals can significantly improve their filtration operations, reduce costs, and ensure a smoother workflow. Understanding the importance of each accessory can lead to more informed decisions, resulting in better performance and outcomes in various applications.

Related News