Why Your Industry Needs a Reliable Filter Press Diaphragm

Release time:

2025-05-10

Why Your Industry Needs a Reliable Filter Press Diaphragm Table of Contents 1. Introduction to Filter Press Diaphragms 2. The Importance of Filter Press Diaphragms in the Chemical Industry 3. How Filter Press Diaphragms Work 4. Key Benefits of Using a Reliable Filter Press Diaphragm 5. Maintenance Tips for Longevity 6. How to Choose the Right Filter Press Diaphragm

Why Your Industry Needs a Reliable Filter Press Diaphragm

Table of Contents

- 1. Introduction to Filter Press Diaphragms

- 2. The Importance of Filter Press Diaphragms in the Chemical Industry

- 3. How Filter Press Diaphragms Work

- 4. Key Benefits of Using a Reliable Filter Press Diaphragm

- 5. Maintenance Tips for Longevity

- 6. How to Choose the Right Filter Press Diaphragm

- 7. Common Issues and Solutions

- 8. Case Studies: Success Stories in Various Industries

- 9. FAQs about Filter Press Diaphragms

- 10. Conclusion

1. Introduction to Filter Press Diaphragms

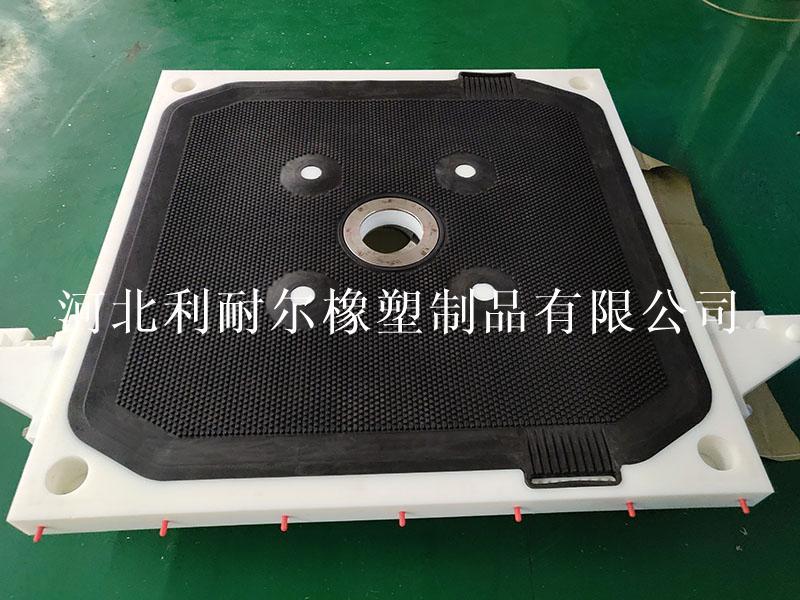

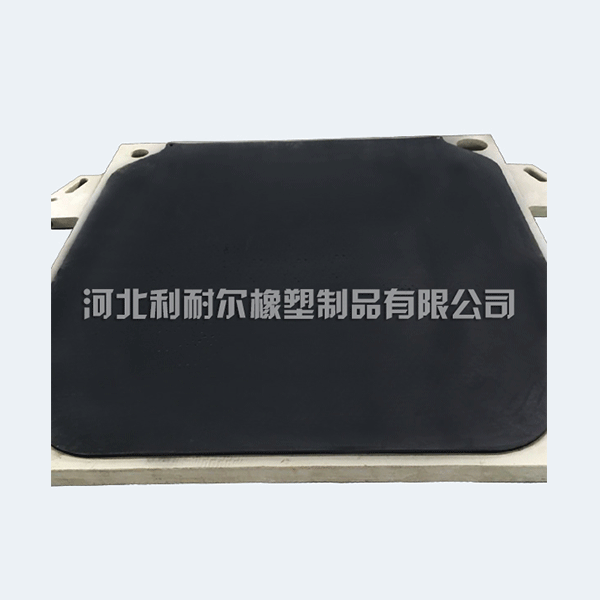

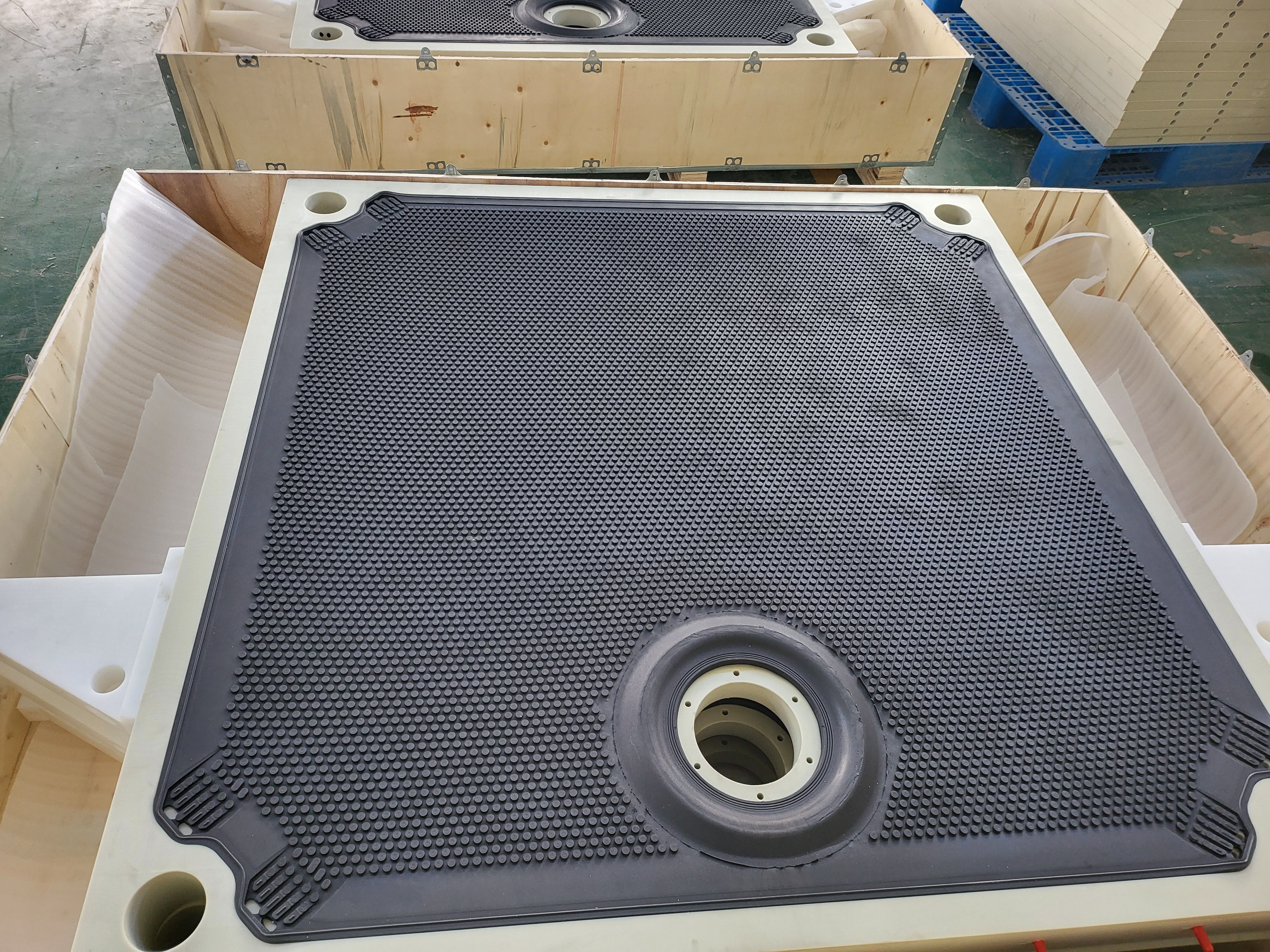

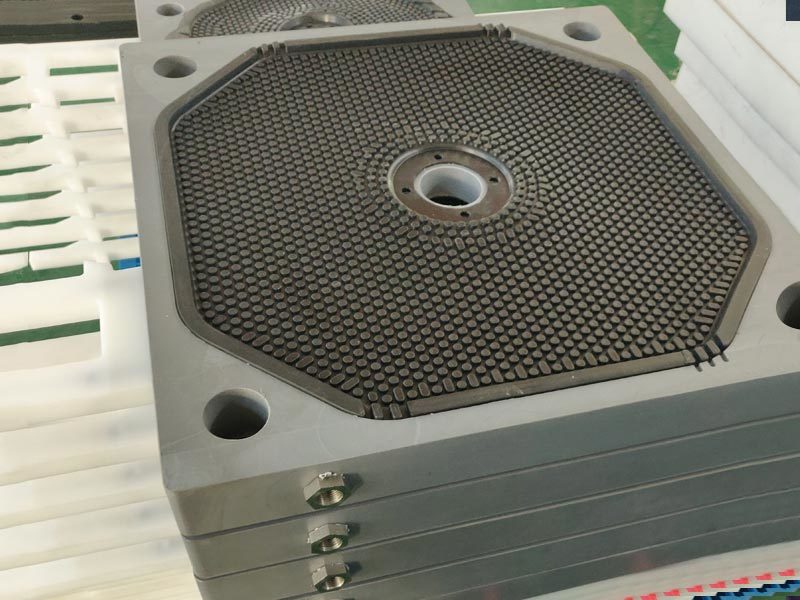

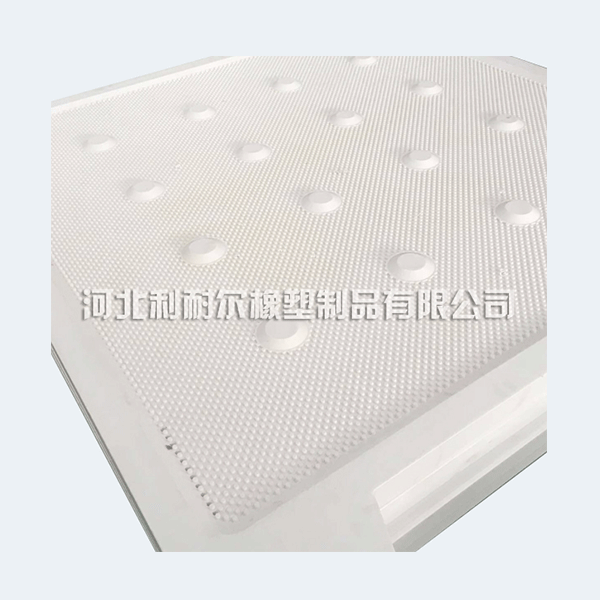

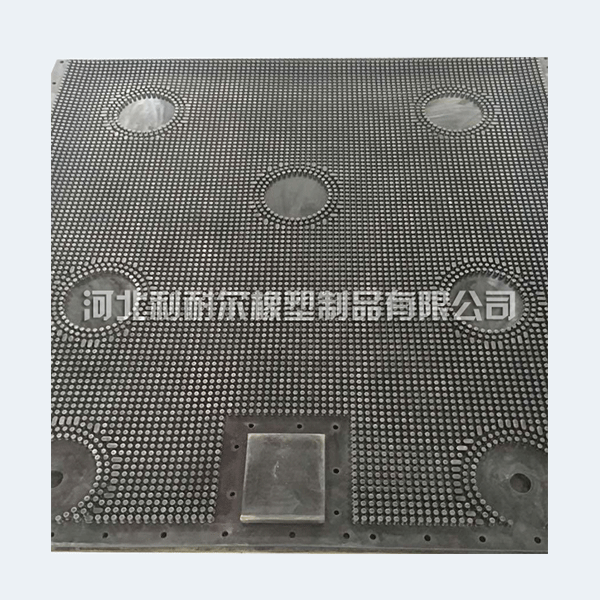

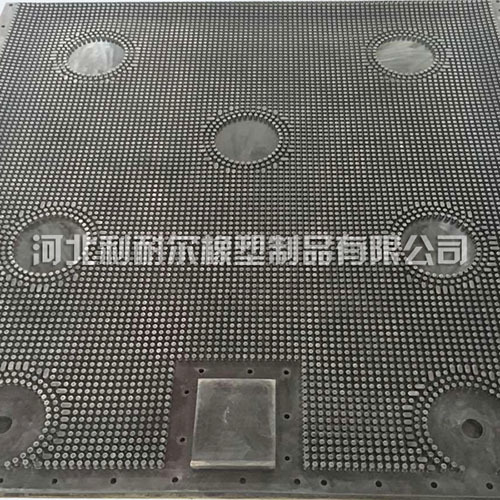

In the complex world of chemical and plastic manufacturing, filtration plays a pivotal role in ensuring product purity and operational efficiency. A **filter press diaphragm** serves as a crucial component in this process, acting as a barrier that separates solids from liquids during filtration. This article delves into the necessity of utilizing a reliable filter press diaphragm in your industrial applications, emphasizing its benefits, maintenance strategies, and selection criteria.

2. The Importance of Filter Press Diaphragms in the Chemical Industry

The **chemical industry** relies heavily on filtration systems to produce high-quality products while minimizing waste. A reliable filter press diaphragm is essential for several reasons:

2.1 Enhancing Efficiency

A high-quality filter press diaphragm can significantly improve the efficiency of the filtration process. By ensuring optimal flow rates and minimizing downtime, businesses can maximize production levels and reduce costs.

2.2 Improving Product Quality

In industries where product purity is paramount, a dependable diaphragm filter ensures that unwanted particles and contaminants are effectively removed. This results in products that meet stringent quality standards, enhancing brand reputation and customer satisfaction.

2.3 Regulatory Compliance

Adhering to environmental regulations is crucial in the chemical industry. A reliable filter press diaphragm helps in achieving compliance by ensuring proper disposal of hazardous waste, thus mitigating environmental impacts.

3. How Filter Press Diaphragms Work

Understanding the working principle of a filter press diaphragm provides insight into its functionality:

3.1 Filtration Process

During the filtration process, a slurry is pumped into the filter press. The diaphragm, typically made of elastomeric material, expands and contracts to aid in the removal of liquid from the solids. This action not only separates the two phases but also helps in cake formation, which can be removed after the process is complete.

3.2 Cycle Phases

The filtration process consists of phases: filling, filtration, washing, and cake discharge. The diaphragm plays a critical role in each of these phases by facilitating the efficient removal of liquid and maximizing solid recovery.

4. Key Benefits of Using a Reliable Filter Press Diaphragm

Investing in a reliable filter press diaphragm offers numerous benefits:

4.1 Cost Efficiency

A robust diaphragm reduces operational costs by minimizing maintenance and replacement frequency. This leads to lower downtime and increased productivity.

4.2 Enhanced Filtration Performance

Quality diaphragms ensure consistent performance, thereby improving overall filtration efficiency. This translates into higher product yields and less waste.

4.3 Versatility

Reliable filter press diaphragms come in various materials and designs, suitable for different applications across the chemical and plastic industries. Their adaptability ensures that they can meet specific operational needs.

5. Maintenance Tips for Longevity

Proper maintenance is essential for maximizing the lifespan of your filter press diaphragm:

5.1 Regular Inspections

Conduct routine inspections to identify any signs of wear and tear. Early detection can prevent costly failures and extended downtime.

5.2 Cleaning Procedures

Implement systematic cleaning protocols to remove build-up and contaminants. This ensures that the diaphragm operates at optimal efficiency.

5.3 Replacement Schedules

Establish a replacement schedule based on usage and operational conditions. Staying proactive can help avoid unexpected breakdowns.

6. How to Choose the Right Filter Press Diaphragm

Choosing the appropriate filter press diaphragm is paramount for operational efficiency. Consider the following factors:

6.1 Material Compatibility

Ensure that the diaphragm material is compatible with the chemicals being filtered. This prevents degradation and enhances performance.

6.2 Size and Configuration

Select a diaphragm that fits the specific dimensions and configuration of your filter press. Proper fit is crucial for effective filtration.

6.3 Performance Ratings

Evaluate the diaphragm's performance ratings, including flow rates and pressure resistance. This information will guide you in selecting an option that meets your operational demands.

7. Common Issues and Solutions

Even the best filter press diaphragms can encounter problems. Here are common issues and their solutions:

7.1 Leakage

If you experience liquid leakage, inspect for wear or damage. Replacing the diaphragm promptly is critical to avoid contamination and maintain efficiency.

7.2 Incomplete Filtration

Incomplete filtration may indicate blockages in the system or malfunctioning diaphragms. Regular maintenance checks can help identify and resolve these issues quickly.

7.3 Reduced Flow Rates

Decreased flow rates can result from clogging or damage. Cleaning or replacing the diaphragm may be necessary to restore optimal function.

8. Case Studies: Success Stories in Various Industries

Several industries have benefitted from utilizing reliable filter press diaphragms:

8.1 Chemical Manufacturing

A leading chemical manufacturer reported a 30% increase in efficiency after upgrading to a high-quality filter press diaphragm, leading to significant cost savings.

8.2 Plastics Production

In the plastics industry, a company focused on recycling plastic waste improved its product purity ratings by 25% through the implementation of an advanced diaphragm filtration system.

9. FAQs about Filter Press Diaphragms

9.1 What is a filter press diaphragm?

A filter press diaphragm is a component used in filter presses that aids in separating solids from liquids during the filtration process.

9.2 How long does a filter press diaphragm last?

The lifespan of a filter press diaphragm depends on usage and maintenance but typically ranges from 1 to 5 years.

9.3 Can I use the same diaphragm for different applications?

It is not advisable to use the same diaphragm for different applications without considering material compatibility and performance requirements.

9.4 How can I improve the performance of my filter press diaphragm?

Regular maintenance, including inspections, cleanings, and timely replacements, can enhance the performance of your filter press diaphragm.

9.5 What are the signs of a failing filter press diaphragm?

Signs of a failing diaphragm include leaks, reduced flow rates, incomplete filtration, and visible wear or damage.

10. Conclusion

In the fast-paced realm of the chemical and plastic industries, the importance of a reliable filter press diaphragm cannot be overstated. By enhancing efficiency, ensuring product quality, and maintaining regulatory compliance, a high-quality diaphragm is a sound investment for any manufacturing operation. Through careful selection and diligent maintenance, businesses can optimize their filtration processes, leading to increased productivity and reduced operational costs. Prioritizing a reliable filter press diaphragm will not only benefit your operations today but also strengthen your position for future growth in the competitive market.

Related News