Understanding Filter Press Plates: Essential Insights for the Chemical and Plastics Industry

Release time:

2025-05-06

Filter press plates are integral components used in the filtration process, especially in industries such as chemicals and plastics. These plates play a pivotal role in the separation of solids from liquids, which is a common requirement in various manufacturing and processing applications. Understanding the fundamental aspects of filter press plates can significantly enhance operational efficienc

Filter press plates are integral components used in the filtration process, especially in industries such as chemicals and plastics. These plates play a pivotal role in the separation of solids from liquids, which is a common requirement in various manufacturing and processing applications. Understanding the fundamental aspects of filter press plates can significantly enhance operational efficiency and product quality.

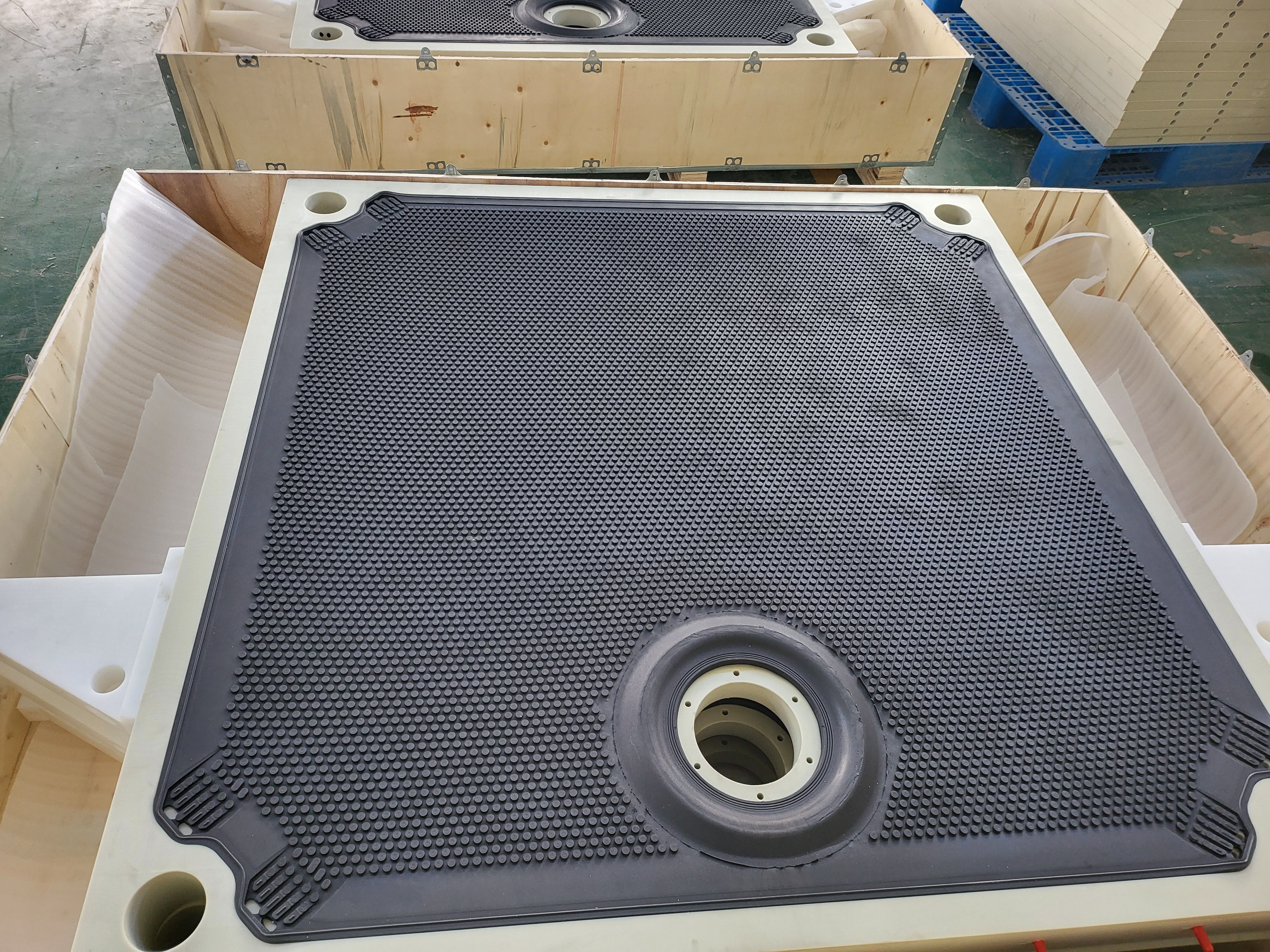

A filter press operates by using a series of plates to create chambers where the slurry is introduced. As the pressure is applied, the liquid is forced out, leaving behind solid particles trapped on the filter cloth. This separation process is crucial in the chemical industry, where the purity of the final product is paramount. The choice of filter press plate can directly influence the efficiency of this process.

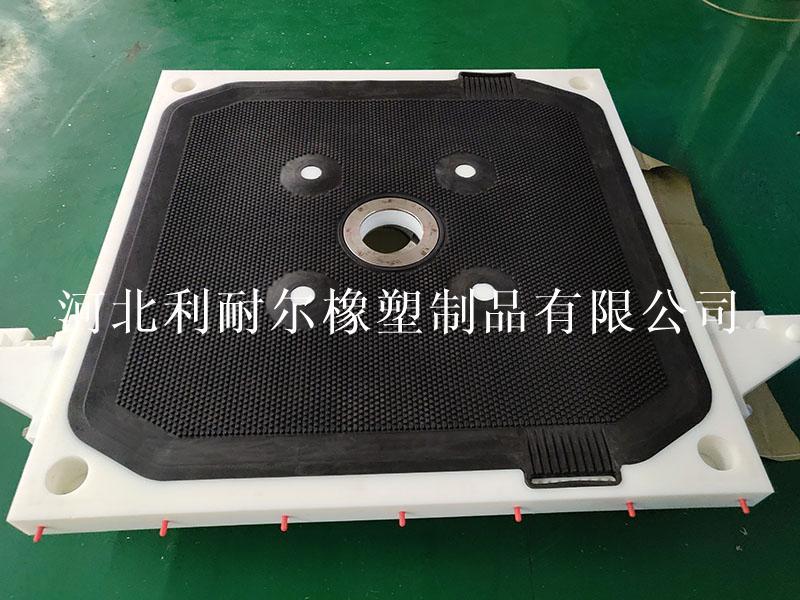

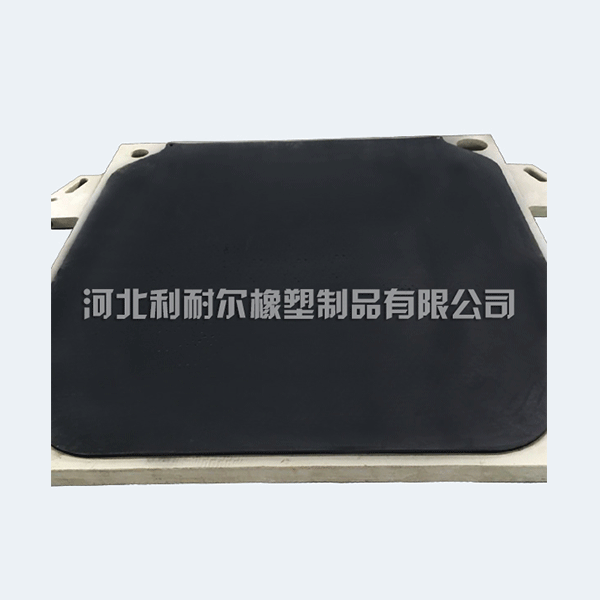

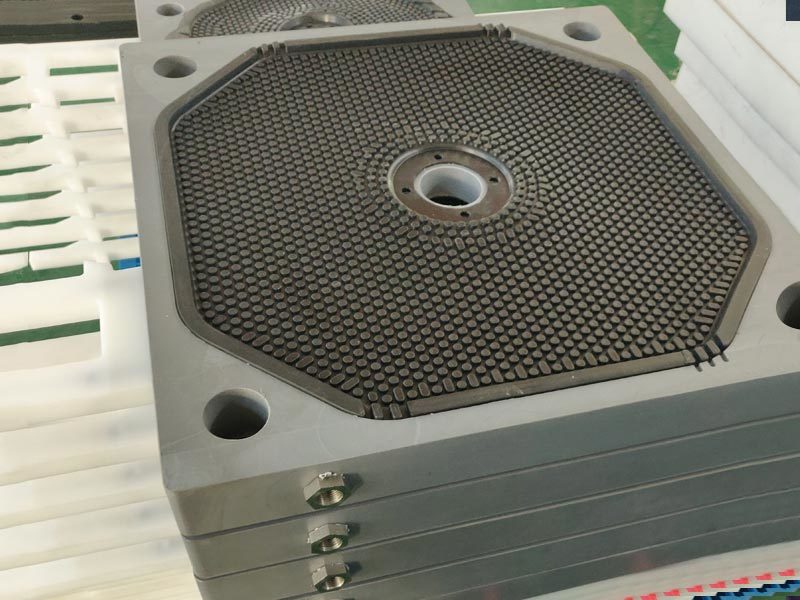

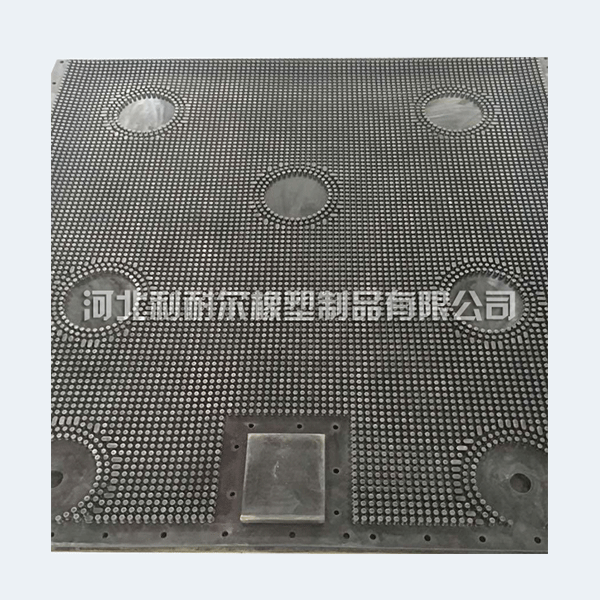

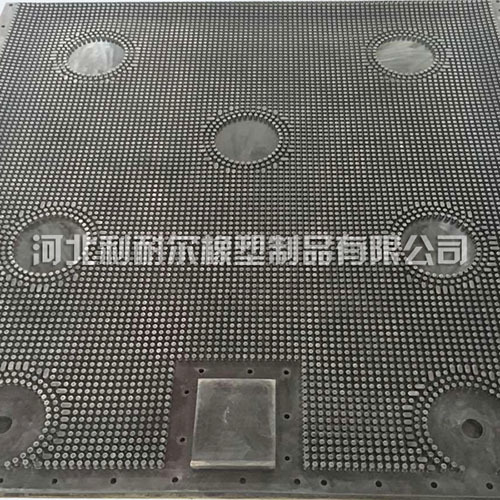

There are several types of filter press plates, including recessed chamber plates, membrane plates, and plate and frame configurations. Recessed chamber plates are commonly used for their ability to accommodate larger volumes of slurry, while membrane plates can enhance filtration efficiency by allowing for a second stage of pressing after the initial filtration. Understanding these variations enables industry professionals to select the most suitable type for their specific applications, optimizing both performance and cost-effectiveness.

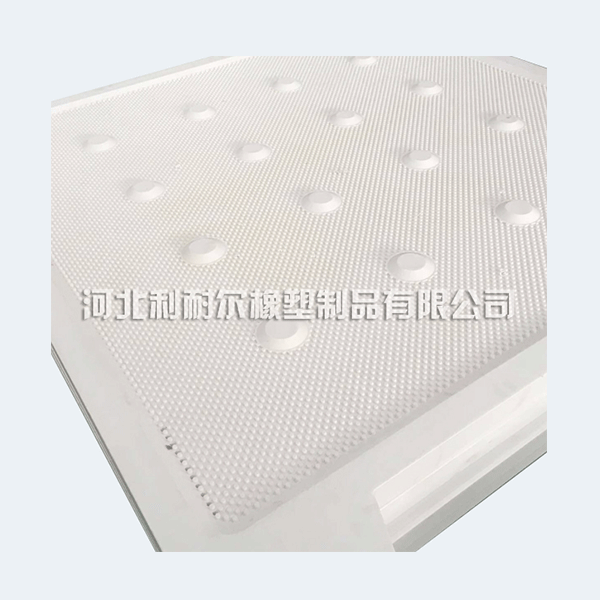

In addition to the type of plate, the material used is also a significant consideration. Filter press plates are typically made from materials like polypropylene, which offers excellent chemical resistance, or stainless steel, known for its durability and strength. The selection of material should align with the type of chemicals being processed and the operational conditions to ensure longevity and reliability.

Maintenance of filter press plates is another critical aspect that should not be overlooked. Regular inspections can identify wear and tear, preventing unexpected downtime. Cleaning protocols should be established to remove any residue that may affect filtration performance. Additionally, proper handling during installation and maintenance can extend the lifespan of the plates, ultimately contributing to more efficient operations.

In conclusion, filter press plates are essential elements in the filtration processes within the chemical and plastics industries. By understanding their types, materials, and maintenance requirements, industry professionals can make informed decisions that enhance the effectiveness of their operations. Investing time in selecting the right filter press plates and adhering to proper maintenance practices will lead to improved product quality and operational efficiency.

A filter press operates by using a series of plates to create chambers where the slurry is introduced. As the pressure is applied, the liquid is forced out, leaving behind solid particles trapped on the filter cloth. This separation process is crucial in the chemical industry, where the purity of the final product is paramount. The choice of filter press plate can directly influence the efficiency of this process.

There are several types of filter press plates, including recessed chamber plates, membrane plates, and plate and frame configurations. Recessed chamber plates are commonly used for their ability to accommodate larger volumes of slurry, while membrane plates can enhance filtration efficiency by allowing for a second stage of pressing after the initial filtration. Understanding these variations enables industry professionals to select the most suitable type for their specific applications, optimizing both performance and cost-effectiveness.

In addition to the type of plate, the material used is also a significant consideration. Filter press plates are typically made from materials like polypropylene, which offers excellent chemical resistance, or stainless steel, known for its durability and strength. The selection of material should align with the type of chemicals being processed and the operational conditions to ensure longevity and reliability.

Maintenance of filter press plates is another critical aspect that should not be overlooked. Regular inspections can identify wear and tear, preventing unexpected downtime. Cleaning protocols should be established to remove any residue that may affect filtration performance. Additionally, proper handling during installation and maintenance can extend the lifespan of the plates, ultimately contributing to more efficient operations.

In conclusion, filter press plates are essential elements in the filtration processes within the chemical and plastics industries. By understanding their types, materials, and maintenance requirements, industry professionals can make informed decisions that enhance the effectiveness of their operations. Investing time in selecting the right filter press plates and adhering to proper maintenance practices will lead to improved product quality and operational efficiency.

Related News