Why Every Chemical Plant Needs a Reliable Filter Press Grille

Release time:

2025-05-02

Why Every Chemical Plant Needs a Reliable Filter Press Grille Introduction to Filter Press Grilles in Chemical Manufacturing The chemical industry is characterized by a multitude of manufacturing processes that require precision and reliability. Among the essential components in this realm is the **filter press grille**, an integral part of solid-liquid separation in various chemical processes. Un

Why Every Chemical Plant Needs a Reliable Filter Press Grille

Introduction to Filter Press Grilles in Chemical Manufacturing

The chemical industry is characterized by a multitude of manufacturing processes that require precision and reliability. Among the essential components in this realm is the **filter press grille**, an integral part of solid-liquid separation in various chemical processes. Understanding why every chemical plant needs a reliable filter press grille involves delving into its functions, benefits, and the impact on overall operational efficiency.

What is a Filter Press Grille?

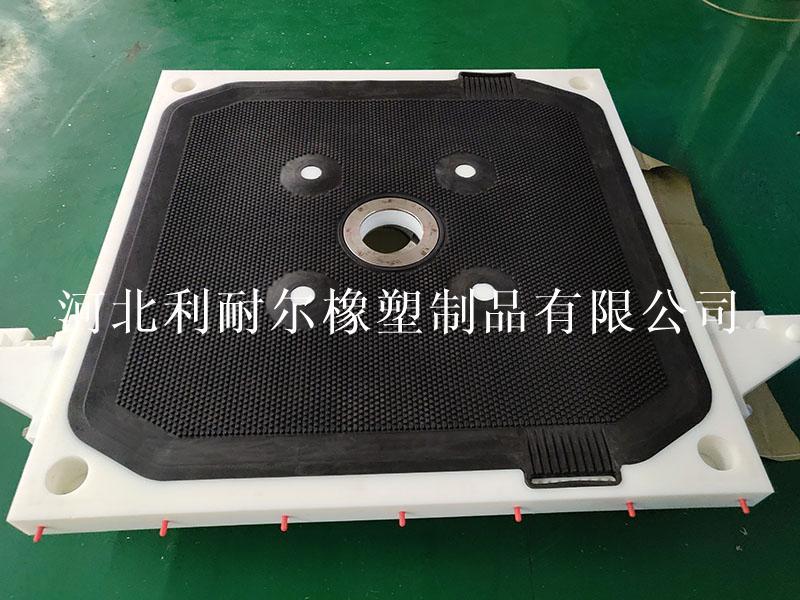

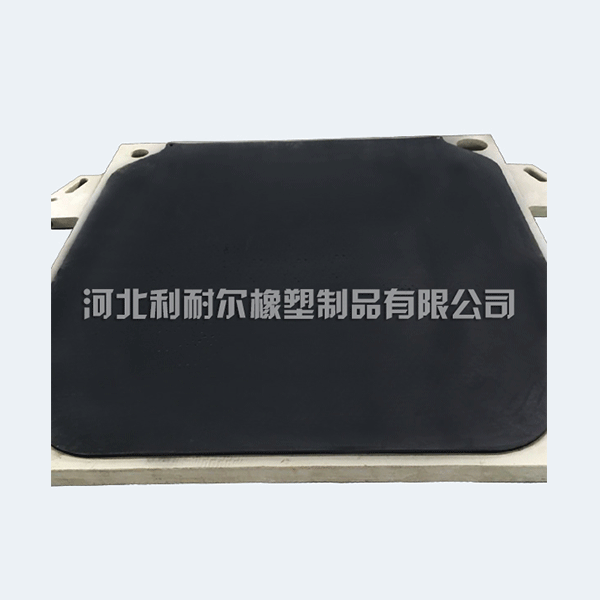

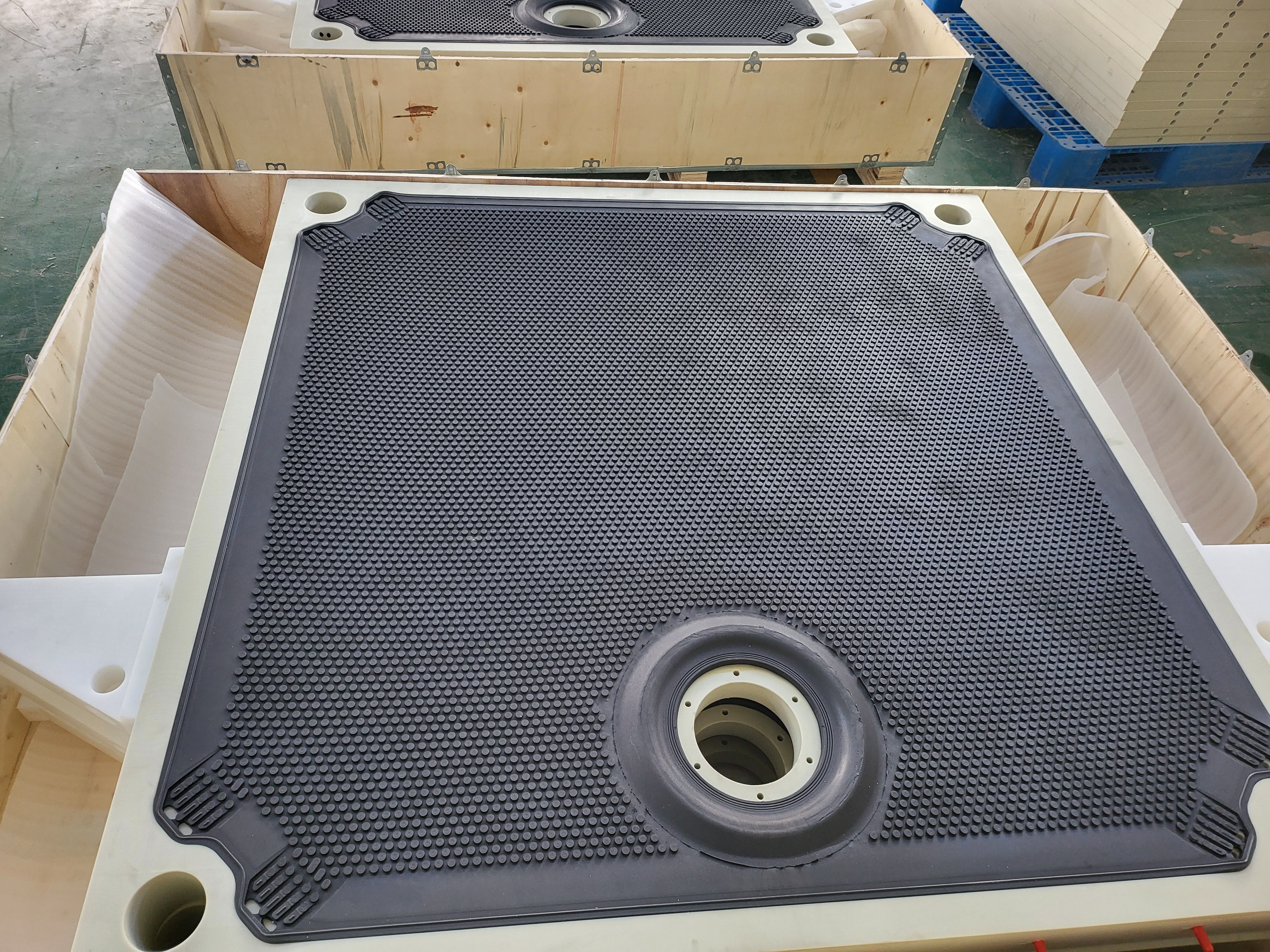

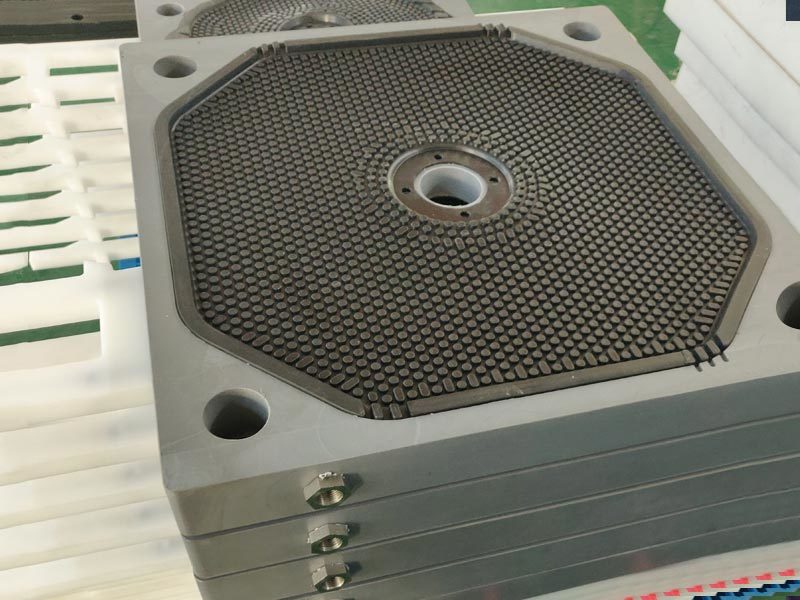

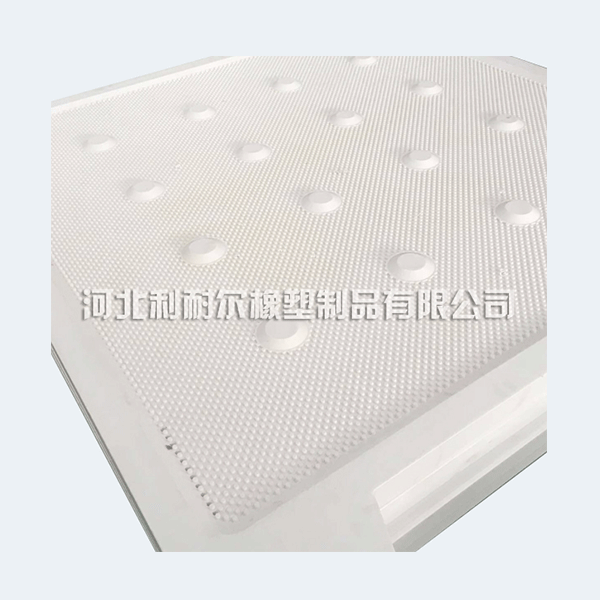

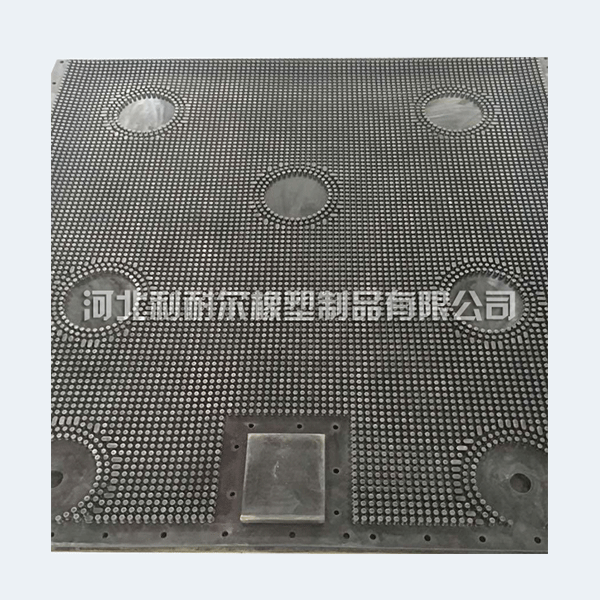

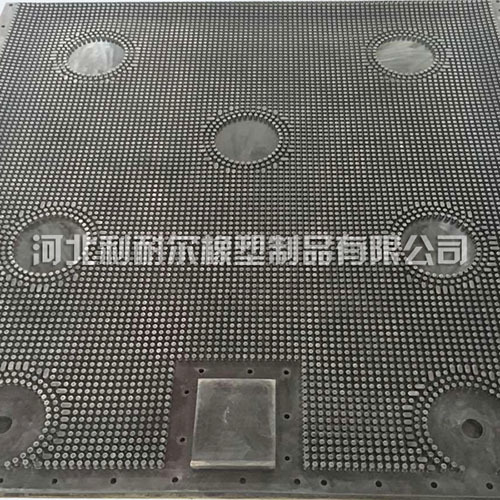

A filter press grille is a mechanical device used to separate solids from liquids in various industrial applications, particularly within chemical processing plants. It functions by applying pressure to a slurry, forcing the liquid through a permeable membrane while retaining solid particles. This process is crucial for **ensuring product quality**, enhancing recovery rates, and minimizing waste.

The Importance of Filtration in Chemical Processing

Filtration is vital for maintaining the purity of chemical products. Contaminants can alter chemical reactions and degrade product quality. A **reliable filter press grille** ensures that impurities are effectively removed, thereby guaranteeing that the final product meets stringent industry standards.

Key Benefits of Using a Reliable Filter Press Grille

1. **Enhanced Efficiency**: A dependable filter press grille optimizes the separation process, leading to improved throughput times and reduced operational delays.

2. **Cost-Effectiveness**: Investing in quality filtration systems reduces the need for frequent maintenance and replacements, leading to lower operational costs in the long run.

3. **Environmental Compliance**: By effectively removing contaminants, filter press grilles help chemical plants meet environmental regulations, ensuring compliance and avoiding penalties.

4. **Improved Product Quality**: The removal of unwanted solids ensures that the chemical products maintain high purity levels, essential for many applications.

5. **Waste Reduction**: Efficient filtration minimizes waste generation, contributing to sustainable operations and lower disposal costs.

Types of Filter Press Grilles Used in Chemical Plants

Chemical plants utilize various types of filter press grilles depending on the specific requirements of their processes. Understanding these types is essential for making informed decisions about filtration solutions.

1. Plate and Frame Filter Press

This traditional type of filter press consists of multiple plates and frames that hold the filter cloths. It’s widely used due to its versatility and effectiveness in separating a range of slurry types.

2. Automatic Filter Press

An automatic filter press features an automated mechanism for cake discharge and washing, significantly reducing labor costs and enhancing efficiency. It’s ideal for high-volume applications.

3. Recessed Chamber Filter Press

Designed for high solids content, this type of filter press has recessed chambers that allow for the collection of larger volumes of solids, making it suitable for heavy-duty applications.

4. Membrane Filter Press

This advanced filtration system utilizes inflatable membranes to enhance cake washing and increase cake dryness, making it perfect for applications requiring high purity and low moisture content.

Factors to Consider When Choosing a Filter Press Grille

Selecting the right filter press grille for a chemical plant involves several considerations to ensure optimal performance and efficiency.

1. Type of Slurry

Understanding the characteristics of the slurry, including particle size, viscosity, and concentration, is crucial for selecting the appropriate filter press grille.

2. Desired Filtration Rate

The required filtration rate dictates the size and type of filter press needed. Higher filtration rates often require more advanced systems capable of handling increased volumes.

3. Space Constraints

Chemical plants often operate within spatial limitations. Selecting a filter press grille that fits within the available space while meeting operational needs is essential.

4. Maintenance Requirements

Consideration of the maintenance cycle and ease of access to components for cleaning and servicing will impact long-term operational efficiency.

5. Budget Constraints

While it’s important to invest in quality equipment, budget constraints must also be considered. A well-rounded approach will yield the best value over time.

Maintenance of Filter Press Grilles

Proper maintenance is crucial to ensuring the longevity and reliability of filter press grilles in chemical plants.

Regular Inspection

Routine inspections help identify wear and tear before they lead to significant issues. Checking for leaks, wear on filter plates, and the integrity of seals can prevent costly downtimes.

Cleaning Protocols

Regular cleaning of the filter press components is vital for maintaining performance. Implementing effective cleaning protocols ensures that contaminants do not affect the filtration process.

Replacement of Components

Identifying when to replace worn-out components, such as filter plates and membranes, is key to maintaining operational efficiency.

The Role of Technology in Filter Press Grilles

Advancements in technology have significantly impacted the design and functionality of filter press grilles, enhancing their efficiency and ease of use.

Smart Automation

Incorporating smart automation features allows for real-time monitoring and control of filtration processes, improving efficiency and reducing manual intervention.

Data Analytics

Utilizing data analytics aids in optimizing the filtration process by analyzing performance metrics and identifying areas for improvement.

Sustainable Design

Modern filter press grilles are increasingly designed with sustainability in mind, using materials and processes that minimize environmental impact.

Case Studies: Successful Implementation of Filter Press Grilles

Examining real-world applications of filter press grilles highlights their effectiveness and benefits in the chemical industry.

Case Study 1: Reducing Waste in a Chemical Plant

A major chemical manufacturer implemented a recessed chamber filter press that significantly reduced slurry waste. By optimizing the separation process, they achieved a 30% reduction in waste disposal costs.

Case Study 2: Enhancing Product Quality

Another facility upgraded to a membrane filter press, resulting in higher product purity levels and a 25% increase in recovery rates, demonstrating the value of investing in reliable filtration technology.

Frequently Asked Questions (FAQs)

1. What is the primary function of a filter press grille in a chemical plant?

The primary function is to separate solids from liquids, ensuring product purity and operational efficiency.

2. How often should a filter press grille be maintained?

Regular maintenance should occur monthly, with detailed inspections and cleaning performed quarterly.

3. What types of slurries can be processed by a filter press grille?

Filter press grilles can handle a variety of slurries, including those with high solids content and various viscosity levels.

4. What are the signs that a filter press grille needs replacement?

Signs include reduced filtration efficiency, unusual noises, leaks, and visible wear on components.

5. Can automation improve the performance of filter press grilles?

Yes, automation can enhance performance through real-time monitoring and streamlined operations, leading to increased efficiency and reduced labor costs.

Conclusion

A reliable filter press grille is indispensable for the efficient and sustainable operation of chemical plants. By ensuring effective solid-liquid separation, these devices contribute to enhanced product quality, reduced waste, and compliance with environmental regulations. Investing in a high-quality filter press grille is not merely a choice but a necessity for any chemical manufacturer aiming for long-term success and operational excellence.

Related News