A Complete Guide to Selecting the Best 1200 Filter Plate for Your Facility

Release time:

2025-04-24

A Complete Guide to Selecting the Best 1200 Filter Plate for Your Facility Table of Contents 1. Introduction to 1200 Filter Plates 2. Understanding Filter Plates: Key Characteristics 3. Types of 1200 Filter Plates Available 4. Criteria for Selecting the Right Filter Plate 4.1 Material Selection 4.2 Size and Dimensions 4.3 Filter Media

A Complete Guide to Selecting the Best 1200 Filter Plate for Your Facility

Table of Contents

- 1. Introduction to 1200 Filter Plates

- 2. Understanding Filter Plates: Key Characteristics

- 3. Types of 1200 Filter Plates Available

- 4. Criteria for Selecting the Right Filter Plate

- 4.1 Material Selection

- 4.2 Size and Dimensions

- 4.3 Filter Media

- 4.4 Compatibility with Existing Equipment

- 5. Installation and Maintenance Tips

- 6. Cost Considerations for 1200 Filter Plates

- 7. Common Issues and Solutions

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to 1200 Filter Plates

In various industrial applications, **filter plates** play a crucial role in ensuring the efficiency of operations. The **1200 filter plate** is particularly notable for its versatility and performance in filtration processes. This guide aims to provide a comprehensive overview of selecting the best 1200 filter plate for your facility, keeping in mind critical factors such as material, size, compatibility, and maintenance.

2. Understanding Filter Plates: Key Characteristics

Filter plates are designed to separate solids from liquids in various industrial settings. Several fundamental characteristics define the effectiveness of a filter plate:

Porosity

The **porosity** of a filter plate determines its ability to retain particles while allowing liquid to flow through. High porosity typically allows for better flow rates, but may compromise filtration efficiency.

Durability

Durability is vital when selecting filter plates, especially in demanding environments. Materials should resist wear and chemical corrosion, ensuring longevity.

Temperature and Pressure Resistance

Understanding the operational **temperature** and **pressure** limits of filter plates is essential. The selected filter plate must withstand these conditions without losing functionality.

3. Types of 1200 Filter Plates Available

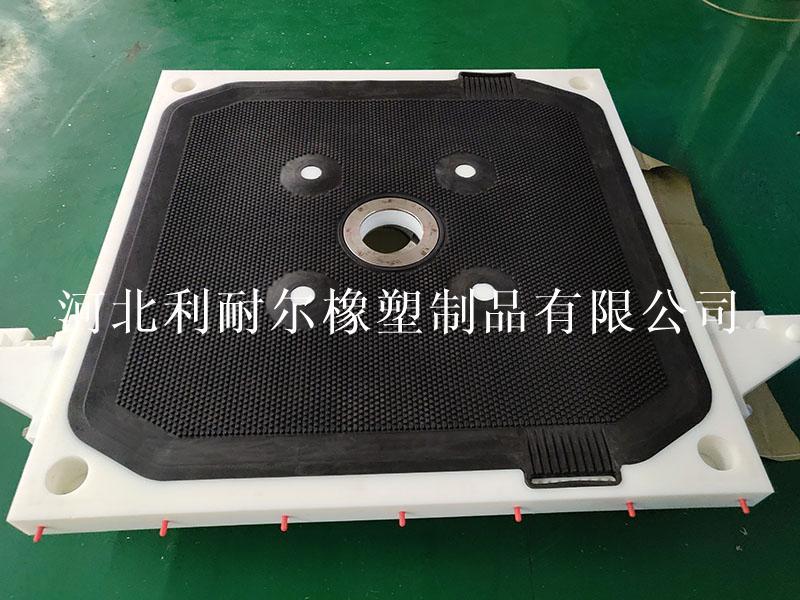

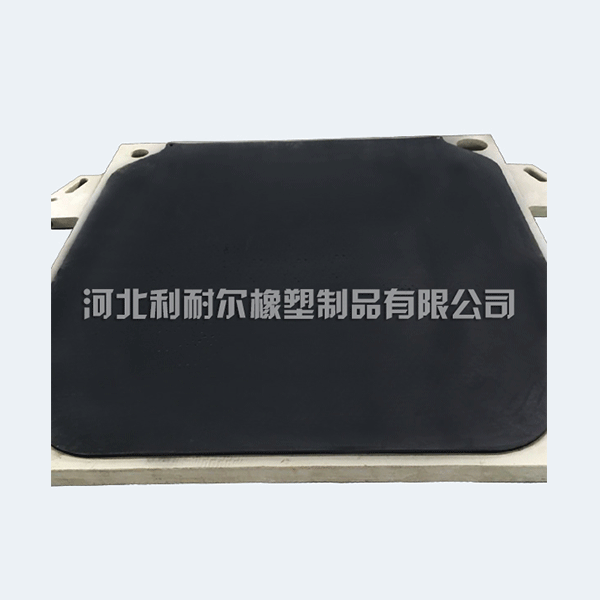

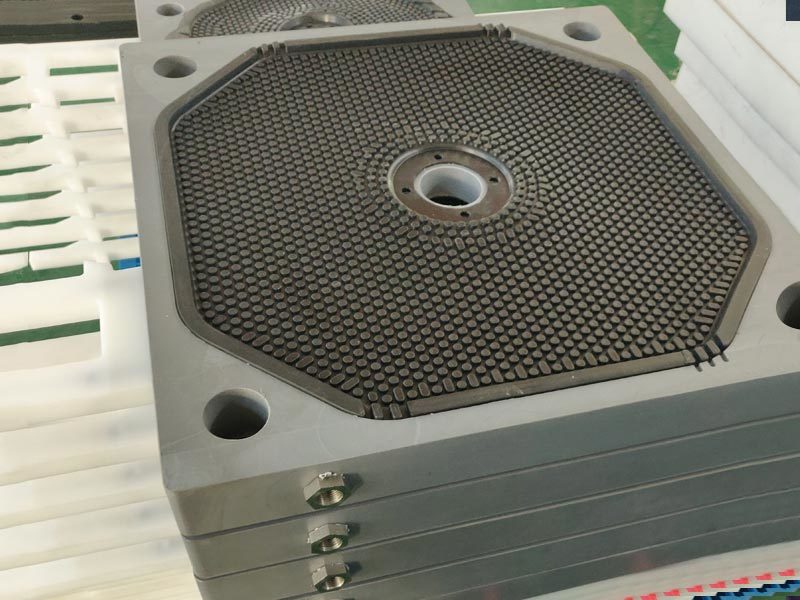

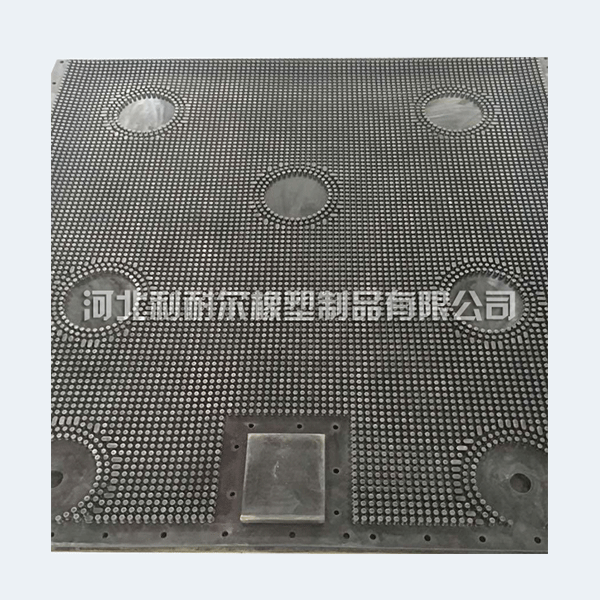

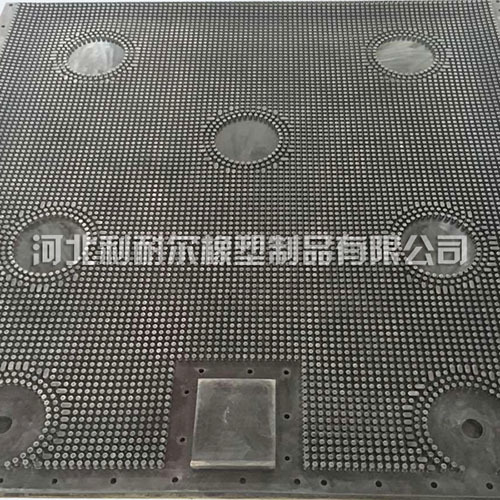

There are several **types of 1200 filter plates** on the market, each designed for specific applications. Understanding these types can help in selecting the most suitable option for your needs.

Standard Filter Plates

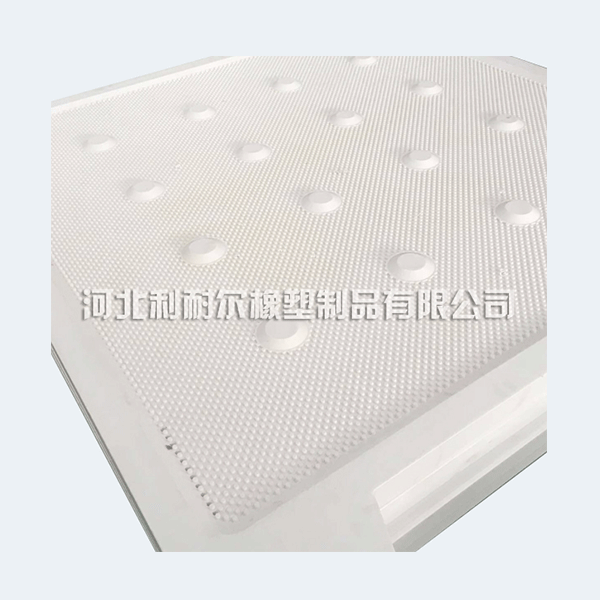

Standard filter plates are widely used for general filtration purposes. They are often made from materials like polypropylene or polyvinylidene fluoride (PVDF).

Specialized Filter Plates

For specific industrial applications, specialized filter plates are available. These may include plates designed to handle high chemical exposure or extreme temperatures.

4. Criteria for Selecting the Right Filter Plate

Choosing the right **1200 filter plate** involves several key criteria. Below, we detail the most critical factors to consider:

4.1 Material Selection

The material of the filter plate significantly influences its performance. Common materials include:

- **Polypropylene**: Lightweight and resistant to many chemicals, ideal for general applications.

- **PVDF**: Offers superior chemical resistance and high-temperature capabilities, suitable for demanding environments.

- **Stainless Steel**: Provides excellent durability and is often used in harsh conditions.

When selecting materials, consider the nature of the fluids being filtered and the operational environment.

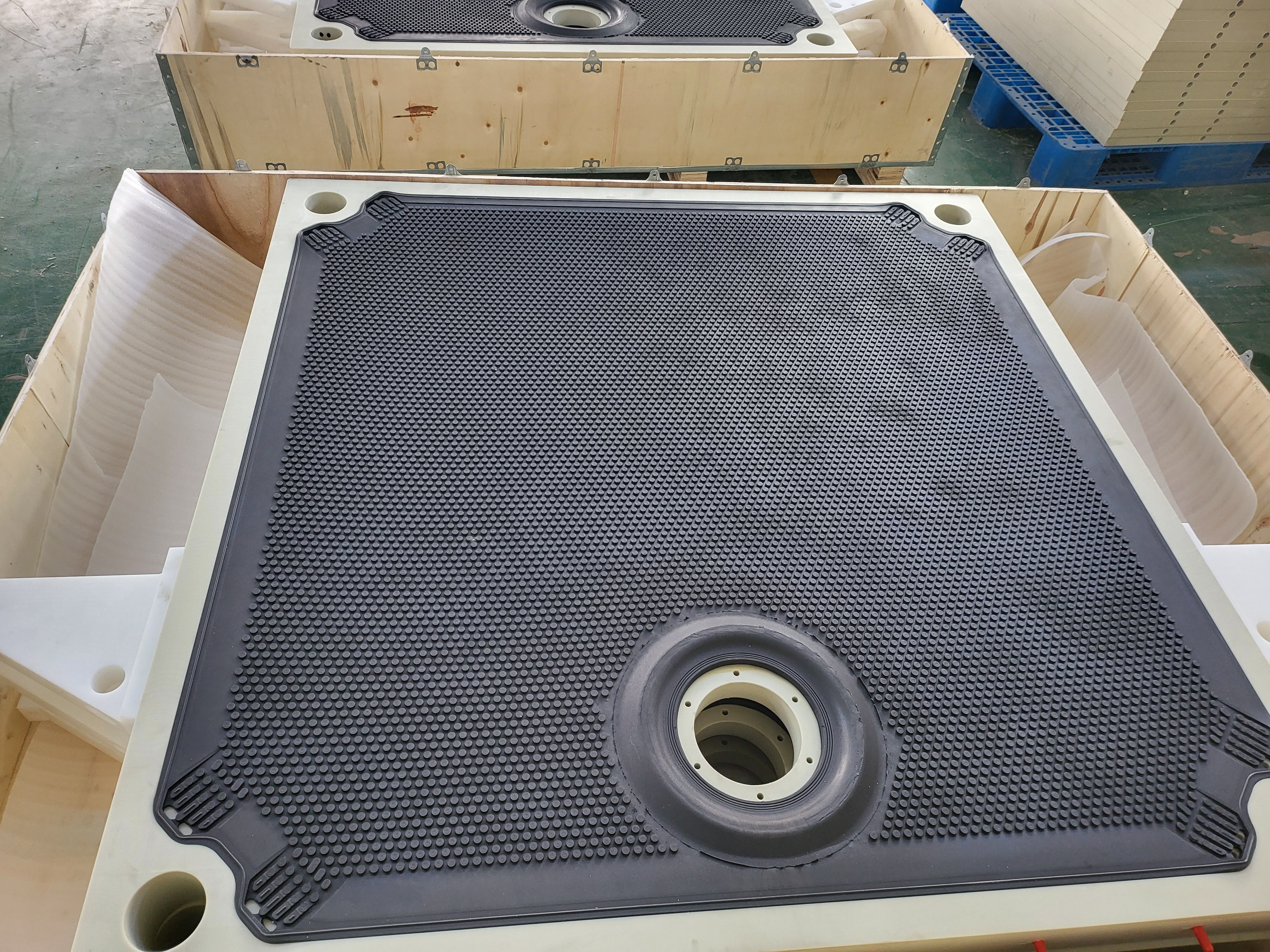

4.2 Size and Dimensions

The size of the filter plate should align with your equipment specifications. Ensure that the **dimensions** fit the **filter press** or filtration system you are using. Accurate measurements will prevent leaks and optimize filtration efficiency.

4.3 Filter Media

The choice of **filter media** affects the filtration process's effectiveness. Options include:

- **Woven fabrics** for high retention rates.

- **Non-woven fabrics** for greater flow rates.

- **Membrane filters** for enhanced purity levels.

It's essential to select a filter media that matches your specific filtration requirements.

4.4 Compatibility with Existing Equipment

Before finalizing your selection, ensure that the 1200 filter plate is compatible with your current filtration system. This includes physical dimensions, connection types, and operational parameters. Compatibility ensures seamless integration, reducing downtime and maintenance costs.

5. Installation and Maintenance Tips

Proper installation and maintenance of your 1200 filter plates are crucial for maximizing their lifespan and performance.

Installation Guidelines

- Follow manufacturer guidelines for installation.

- Ensure all seals and gaskets are intact to prevent leaks.

- Use appropriate tools to avoid damaging the plates during installation.

Maintenance Practices

Regular maintenance can prolong the life of your filter plates. Key practices include:

- **Visual inspections**: Check for signs of wear or damage regularly.

- **Cleaning**: Establish a cleaning schedule based on the type of fluids being filtered. Cleaning prevents clogging and maintains flow rates.

- **Replacement**: Monitor filter performance; replace plates that show significant wear or reduced efficiency.

6. Cost Considerations for 1200 Filter Plates

Cost is a significant factor in filter plate selection. While it may be tempting to opt for the cheapest option, considering the total cost of ownership is vital.

Initial Costs

The price of the filter plate will vary based on material and type. While initial costs are important, they should not be the sole deciding factor.

Long-term Costs

Evaluate the long-term performance and maintenance costs associated with the filter plate. Higher-quality plates may have a higher upfront cost but often lead to lower maintenance and replacement costs over time.

7. Common Issues and Solutions

Understanding potential issues with filter plates can help in proactive management and maintenance.

Clogging

Clogging can occur due to particulate build-up. To mitigate this, implement regular cleaning protocols and consider adjusting the filtration speed.

Leaks

Leaks may indicate improper installation or faulty seals. Regular inspections can help identify and rectify these issues before they escalate.

Wear and Tear

Over time, filter plates will naturally wear. Regular monitoring and scheduled replacements are essential to maintain system efficiency.

8. Frequently Asked Questions (FAQs)

1. What is the lifespan of a 1200 filter plate?

The lifespan varies based on material, usage, and maintenance practices. With proper care, they can last several years.

2. How often should we replace filter plates?

Replacement frequency depends on usage and performance. Regular performance checks will help determine the right time for replacement.

3. Are 1200 filter plates customizable?

Yes, many manufacturers offer customizable options to meet specific operational needs.

4. Can we use 1200 filter plates for different applications?

While some filter plates are versatile, it's best to choose a plate specifically designed for your intended application.

5. What should we do if we experience frequent clogging?

Consider adjusting the filtration process, cleaning more frequently, or selecting a filter plate with a different porosity.

9. Conclusion

Selecting the best 1200 filter plate for your facility is a multi-faceted process that involves understanding various factors such as material, size, and compatibility. By carefully considering these aspects and implementing proper maintenance practices, you can enhance your filtration efficiency, reduce operational costs, and prolong the lifespan of your equipment. Armed with this comprehensive guide, you are now better equipped to make informed decisions that will benefit your facility in the long run.

Related News