How 1000 Filter Plates Transform Filtration Efficiency Across Industries

Release time:

2025-04-16

How 1000 Filter Plates Transform Filtration Efficiency Across Industries Introduction to Filtration Systems Filtration is a crucial process in various industries, from food and beverage to pharmaceuticals and wastewater management. At the heart of effective filtration systems are **filter plates**, which play an essential role in removing impurities and ensuring product quality. Understanding how

How 1000 Filter Plates Transform Filtration Efficiency Across Industries

Introduction to Filtration Systems

Filtration is a crucial process in various industries, from food and beverage to pharmaceuticals and wastewater management. At the heart of effective filtration systems are **filter plates**, which play an essential role in removing impurities and ensuring product quality. Understanding how **1000 filter plates** can significantly enhance filtration efficiency is vital for businesses looking to optimize their operations.

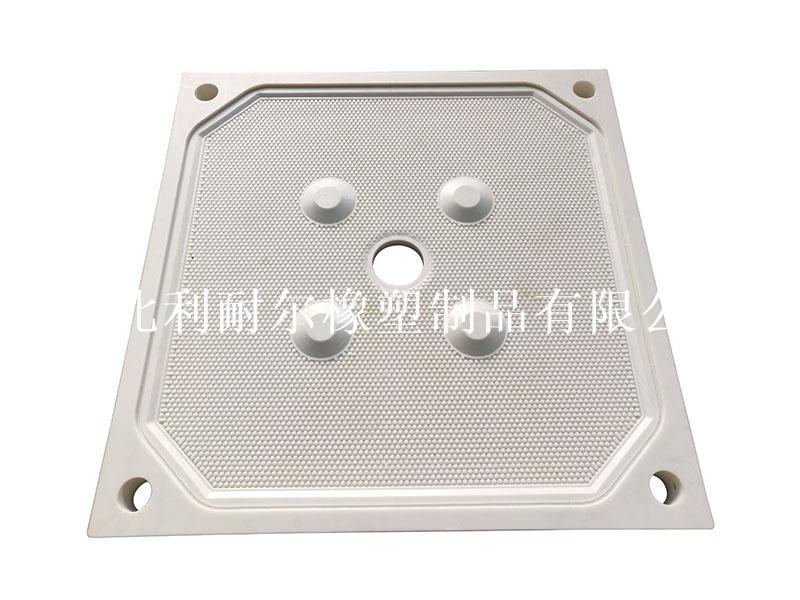

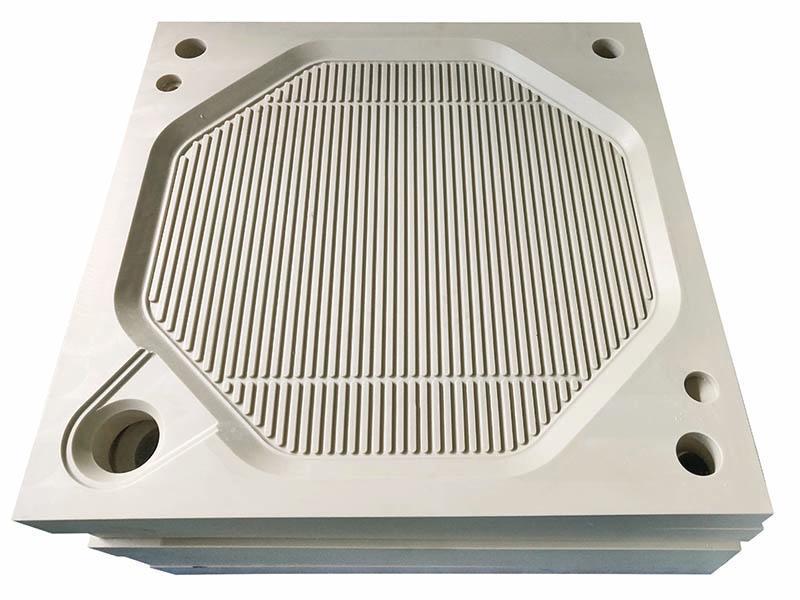

Understanding Filter Plates

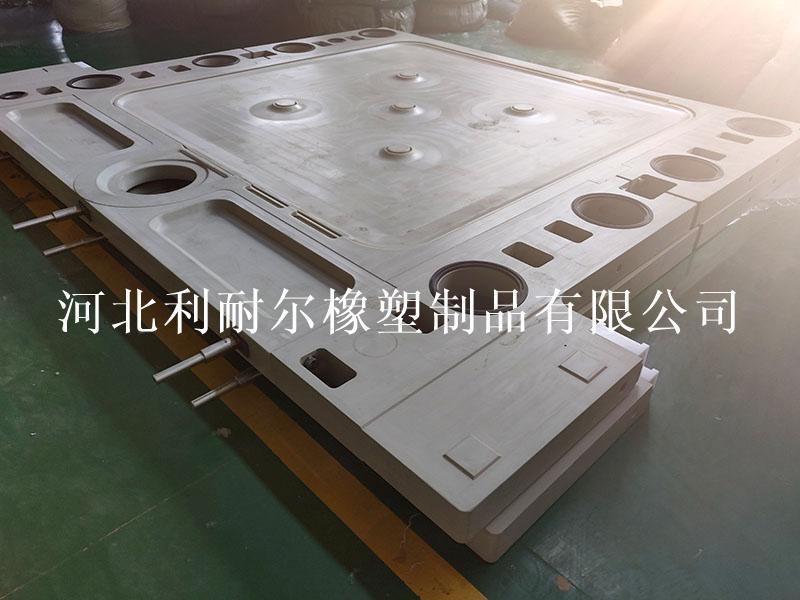

Filter plates are flat, porous materials that allow fluids to pass through while retaining solid particles. They come in various sizes, shapes, and materials, depending on the specific application. The design and structure of filter plates directly influence their filtration performance, making it essential to choose the right type for your process.

The Anatomy of a Filter Plate

A typical filter plate consists of several key components:

- **Filtration Area**: The surface area available for filtering, which determines the volume of liquid that can be processed.

- **Material Composition**: Common materials include polypropylene, polyester, and stainless steel, each offering unique benefits regarding durability and filtration capabilities.

- **Pore Size**: The size of the pores dictates the efficiency of filtration, affecting what contaminants can be captured.

The Role of 1000 Filter Plates in Filtration Efficiency

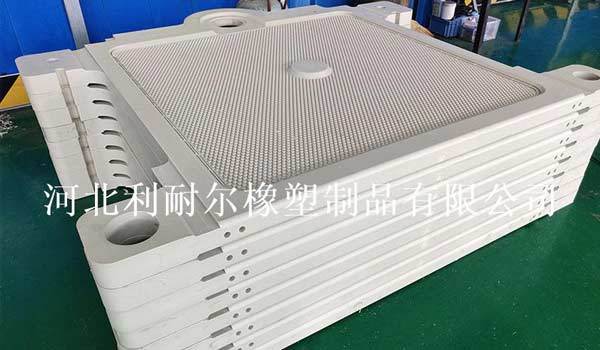

Using 1000 filter plates offers numerous advantages that enhance filtration efficiency. Here, we explore the significant impacts of this quantity on various industrial applications.

1. Increased Filtration Surface Area

Having 1000 filter plates substantially increases the **filtration surface area** available for processing. This expanded surface allows for a greater volume of fluid to be filtered simultaneously, reducing the time required for the filtration process. Industries can significantly improve throughput, leading to higher productivity levels.

2. Enhanced Contaminant Removal

The effectiveness of filtration largely depends on the design and maintenance of filter plates. With 1000 high-quality filter plates, businesses can achieve higher contaminant removal rates. This is particularly important in industries like pharmaceuticals, where product purity is critical.

3. Improved Flow Rates and Reduced Pressure Drop

An optimized number of filter plates allows for improved flow rates through the filtration system. By distributing the fluid evenly across all plates, manufacturers can minimize the pressure drop, which often leads to energy savings and lower operational costs.

Case Study: Wastewater Treatment

In wastewater treatment plants, utilizing 1000 filter plates can lead to a notable reduction in processing time. For example, a facility that previously processed 1,000 gallons of wastewater per hour can increase its capacity to 1,500 gallons per hour simply by implementing additional filter plates.

Application of Filter Plates Across Industries

The versatility of filter plates makes them suitable for various sectors. Below, we explore some key applications.

Food and Beverage Industry

In the food and beverage sector, maintaining product quality and safety is paramount. Filter plates are used to remove impurities from liquids, such as juices, oils, and beer. The clarity and safety of these products rely heavily on the efficiency of the filtration process.

Chemical Manufacturing

Chemical manufacturers often deal with complex mixtures requiring precise filtration to separate solids from liquids. Using a large number of filter plates enables the effective removal of particulates, ensuring product consistency and adherence to safety standards.

Pharmaceuticals and Biotechnology

In pharmaceutical production, filter plates play a crucial role in sterilization and ensuring product purity. The use of 1000 filter plates can enhance the reliability of filtration processes, reducing the risk of contamination and ensuring compliance with stringent regulations.

Mining and Mineral Processing

The mining industry utilizes filter plates to separate valuable minerals from slurries. By deploying numerous filter plates, companies can optimize the recovery rate of minerals while minimizing waste.

Benefits of Using 1000 Filter Plates

Apart from enhancing filtration efficiency, using 1000 filter plates offers several additional benefits.

Cost-Effectiveness

Investing in a significant number of filter plates may seem substantial initially, but the long-term savings on operational costs, maintenance, and increased efficiency can result in a remarkable return on investment.

Scalability

Using 1000 filter plates allows businesses to scale up their operations with ease. As demand increases, companies can quickly adjust their filtration capacities without the need for extensive system overhauls.

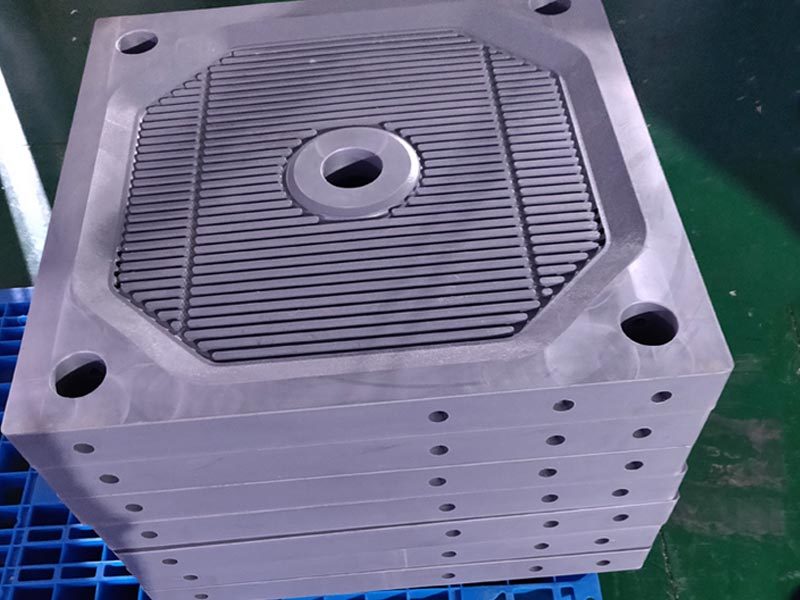

Customization Options

Many manufacturers offer customization options for filter plates. This flexibility enables industries to tailor their filtration solutions to meet specific needs, further enhancing efficiency and effectiveness.

Best Practices for Maintaining Filter Plates

To ensure optimal performance, it’s essential to maintain filter plates properly. Here are some best practices:

Regular Inspections

Routine inspections of filter plates help identify wear and tear, allowing for timely replacements that prevent operational downtime.

Proper Cleaning Techniques

Cleaning filter plates according to manufacturer recommendations can extend their lifespan and maintain filtration efficiency. Backwashing and chemical cleaning are common methods used, depending on the application.

Monitoring Performance Metrics

Tracking performance metrics such as flow rates, pressure drops, and contaminant removal efficiency enables businesses to assess the effectiveness of their filtration systems continually.

Frequently Asked Questions

1. What are the advantages of using filter plates in industrial applications?

Filter plates enhance filtration efficiency by increasing surface area, improving flow rates, and ensuring effective contaminant removal.

2. How do I choose the right filter plate material?

Choosing the right material depends on the specific application, compatibility with the fluids processed, and the required durability.

3. Can I use 1000 filter plates in small-scale operations?

Yes, while 1000 filter plates may seem excessive for small-scale operations, they can increase efficiency and allow for future scalability.

4. How often should filter plates be replaced?

Replacement frequency varies based on usage and maintenance. Regular inspections will help determine the appropriate replacement schedule.

5. What impact do filter plates have on environmental sustainability?

Efficient filtration processes reduce waste and improve resource recovery, contributing positively to environmental sustainability efforts.

Conclusion

The implementation of **1000 filter plates** can drastically enhance filtration efficiency across various industries. By increasing surface area, improving contaminant removal, and ensuring scalability, businesses can optimize their processes and significantly boost productivity. Understanding the critical role of filter plates and adhering to best practices for their maintenance ensures long-term success and efficiency in filtration systems. Investing in these technologies not only improves operational effectiveness but also aligns with sustainability goals, making it a smart choice for the future.

Related News