Understanding the Role and Benefits of 400 Filter Plates in Industrial Applications

Release time:

2025-04-04

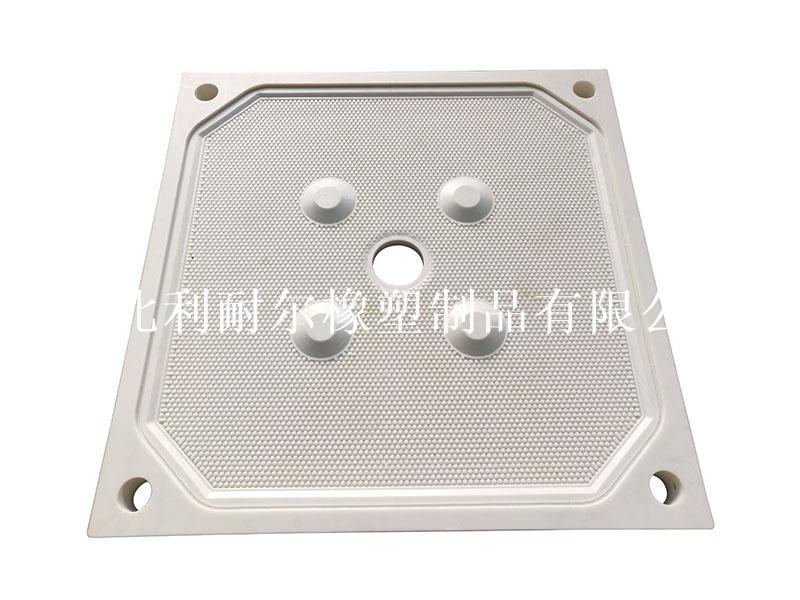

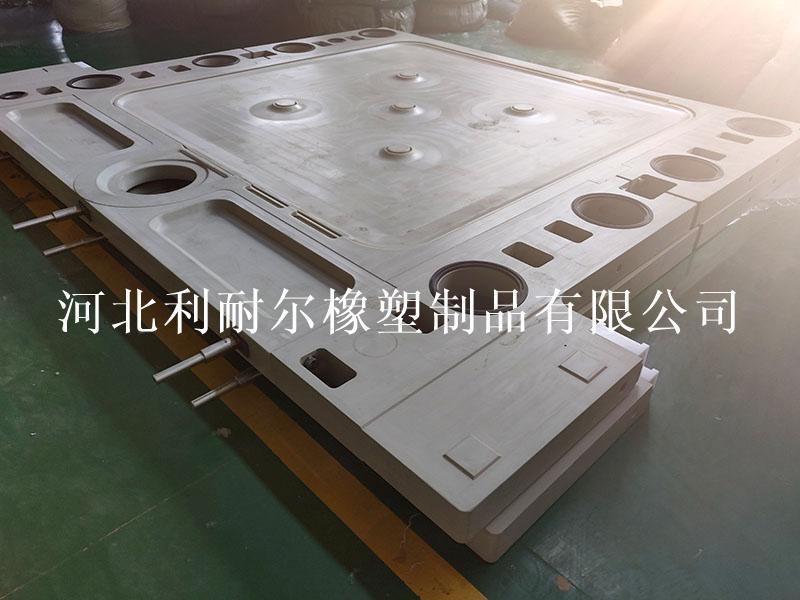

The 400 filter plate is an essential component in various industrial filtration systems, particularly in sectors such as pharmaceuticals, chemicals, and food processing. These plates are designed to separate solids from liquids, thus playing a vital role in maintaining product quality and compliance with industry standards. The primary function of a 400 filter plate is to act as a barrier that al

The 400 filter plate is an essential component in various industrial filtration systems, particularly in sectors such as pharmaceuticals, chemicals, and food processing. These plates are designed to separate solids from liquids, thus playing a vital role in maintaining product quality and compliance with industry standards.

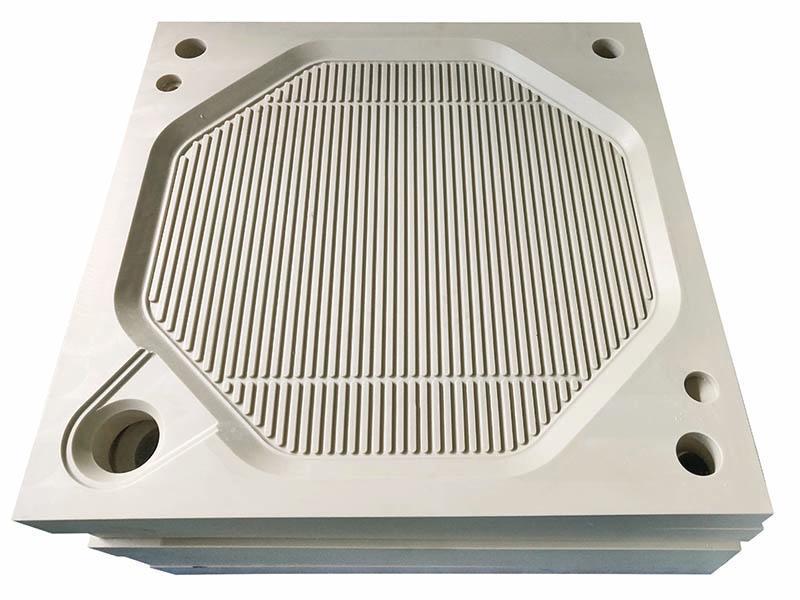

The primary function of a 400 filter plate is to act as a barrier that allows liquid to flow through while retaining solid particles. This process is essential in applications where the presence of impurities can degrade product quality or jeopardize safety. The design and material of these filter plates can significantly influence their efficiency and durability, making it important to choose the right specifications based on the intended application.

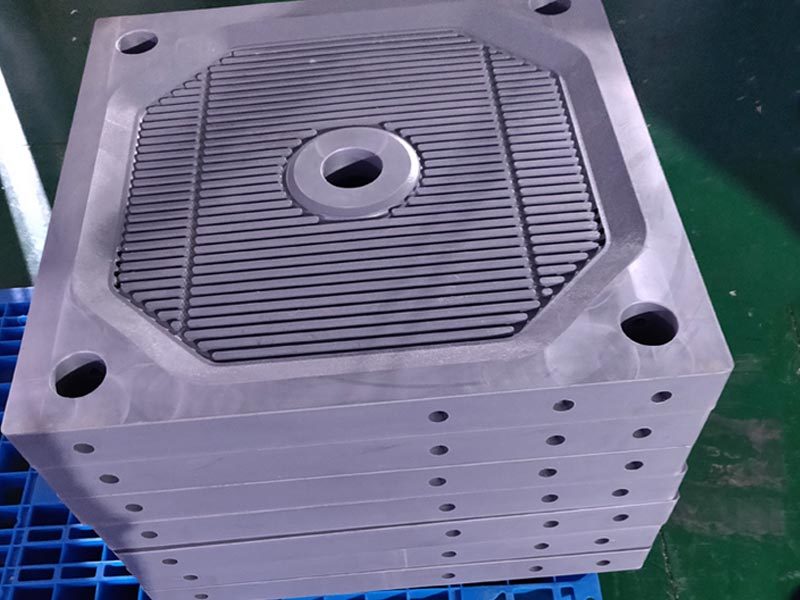

One of the key benefits of using 400 filter plates is their enhanced filtration capabilities. These plates are engineered to provide a large surface area for filtration, which allows for the effective separation of solids from liquids at a relatively low pressure. This is particularly important in industries where the filtration process needs to be both efficient and cost-effective. Additionally, the 400 filter plates can be used in conjunction with various types of filter media, allowing for versatility in handling different types of fluids and contaminants.

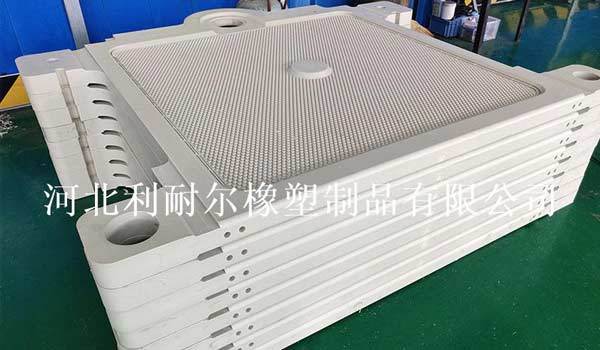

Another significant advantage of using 400 filter plates is their ease of maintenance and replacement. Many filter plates are designed for quick assembly and disassembly, which minimizes downtime during maintenance activities. This is critical for industrial operations that require high uptime and minimal disruption to workflows. Furthermore, the materials used in manufacturing 400 filter plates are often resistant to corrosion and wear, which enhances their longevity and reduces the frequency of replacements.

Additionally, the use of 400 filter plates can lead to improved environmental sustainability. By efficiently separating solids from liquids, these plates can help reduce waste and the need for additional processing steps. This not only lowers operational costs but also contributes to a more sustainable approach to industrial practices.

In conclusion, 400 filter plates are a vital component in industrial filtration systems, offering numerous benefits such as enhanced filtration efficiency, ease of maintenance, and environmental sustainability. Understanding the role and advantages of these filter plates can help professionals make informed decisions in selecting the right filtration solutions for their specific application needs. As industries continue to prioritize quality and efficiency, the importance of effective filtration methods like those provided by 400 filter plates will only grow.

The primary function of a 400 filter plate is to act as a barrier that allows liquid to flow through while retaining solid particles. This process is essential in applications where the presence of impurities can degrade product quality or jeopardize safety. The design and material of these filter plates can significantly influence their efficiency and durability, making it important to choose the right specifications based on the intended application.

One of the key benefits of using 400 filter plates is their enhanced filtration capabilities. These plates are engineered to provide a large surface area for filtration, which allows for the effective separation of solids from liquids at a relatively low pressure. This is particularly important in industries where the filtration process needs to be both efficient and cost-effective. Additionally, the 400 filter plates can be used in conjunction with various types of filter media, allowing for versatility in handling different types of fluids and contaminants.

Another significant advantage of using 400 filter plates is their ease of maintenance and replacement. Many filter plates are designed for quick assembly and disassembly, which minimizes downtime during maintenance activities. This is critical for industrial operations that require high uptime and minimal disruption to workflows. Furthermore, the materials used in manufacturing 400 filter plates are often resistant to corrosion and wear, which enhances their longevity and reduces the frequency of replacements.

Additionally, the use of 400 filter plates can lead to improved environmental sustainability. By efficiently separating solids from liquids, these plates can help reduce waste and the need for additional processing steps. This not only lowers operational costs but also contributes to a more sustainable approach to industrial practices.

In conclusion, 400 filter plates are a vital component in industrial filtration systems, offering numerous benefits such as enhanced filtration efficiency, ease of maintenance, and environmental sustainability. Understanding the role and advantages of these filter plates can help professionals make informed decisions in selecting the right filtration solutions for their specific application needs. As industries continue to prioritize quality and efficiency, the importance of effective filtration methods like those provided by 400 filter plates will only grow.

Related News