How 880 Filter Plates Revolutionize Filtration Efficiency in Industrial Systems

Release time:

2025-03-31

How 880 Filter Plates Revolutionize Filtration Efficiency in Industrial Systems Table of Contents Introduction to 880 Filter Plates Understanding Filtration Systems Design and Structure of 880 Filter Plates Advantages of Using 880 Filter Plates Applications of 880 Filter Plates Maintenance and Care for Optimal Performance Case Studies and Performance Analysis The Future of Filtrat

How 880 Filter Plates Revolutionize Filtration Efficiency in Industrial Systems

Table of Contents

- Introduction to 880 Filter Plates

- Understanding Filtration Systems

- Design and Structure of 880 Filter Plates

- Advantages of Using 880 Filter Plates

- Applications of 880 Filter Plates

- Maintenance and Care for Optimal Performance

- Case Studies and Performance Analysis

- The Future of Filtration Technology

- Conclusion

- FAQs about 880 Filter Plates

Introduction to 880 Filter Plates

In the realm of industrial filtration, **880 filter plates** have emerged as a game-changer. These plates are specifically designed to enhance the efficiency of various filtration systems, ranging from water treatment facilities to chemical processing plants. Their unique characteristics contribute significantly to optimizing filtration processes, which ultimately leads to cost savings and improved productivity.

Understanding Filtration Systems

Filtration systems are integral to numerous industrial operations. They serve to separate solids from liquids or gases, ensuring that the output meets required purity and quality standards. Filtration can occur through different methods, including mechanical, chemical, and biological processes. Understanding these systems is crucial for appreciating the role of **880 filter plates**.

The Role of Filtration in Industrial Processes

Filtration is essential for removing contaminants, safeguarding equipment, and ensuring product quality. It is particularly vital in industries such as pharmaceuticals, food and beverage, and waste management, where purity is non-negotiable. Efficient filtration systems can prevent costly downtime and enhance compliance with environmental regulations.

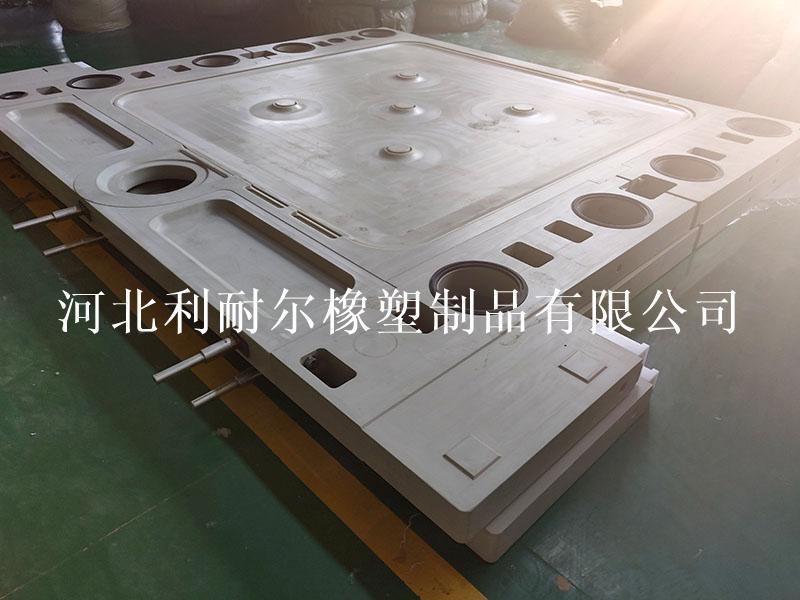

Design and Structure of 880 Filter Plates

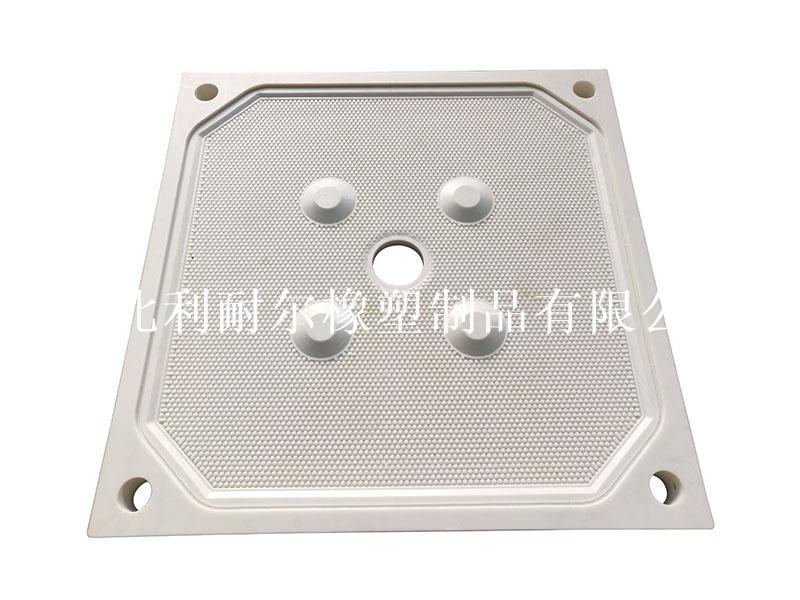

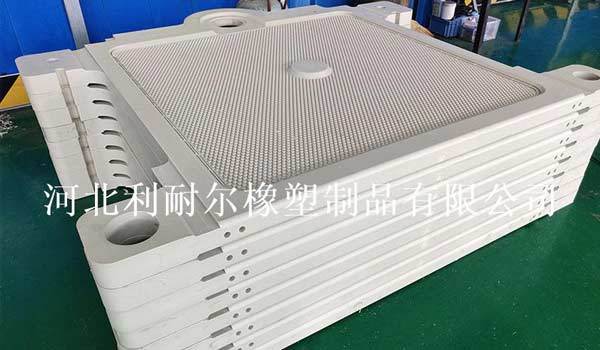

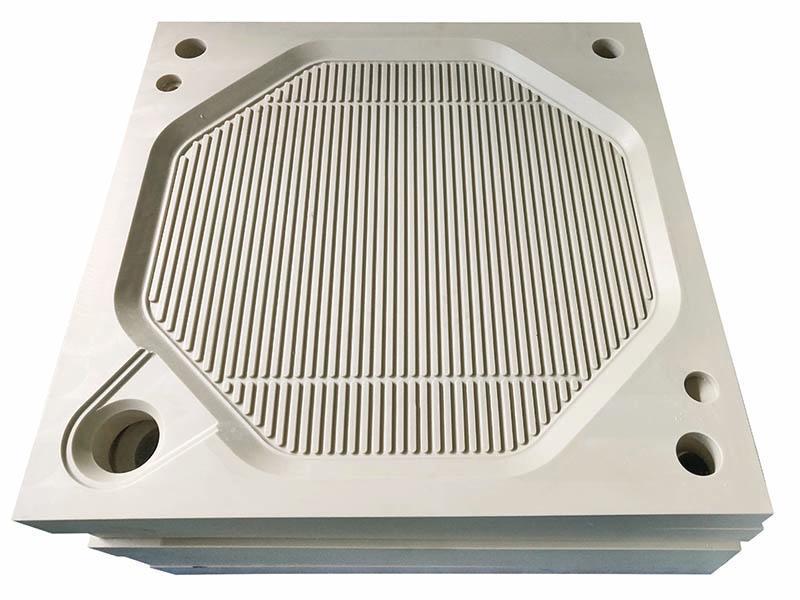

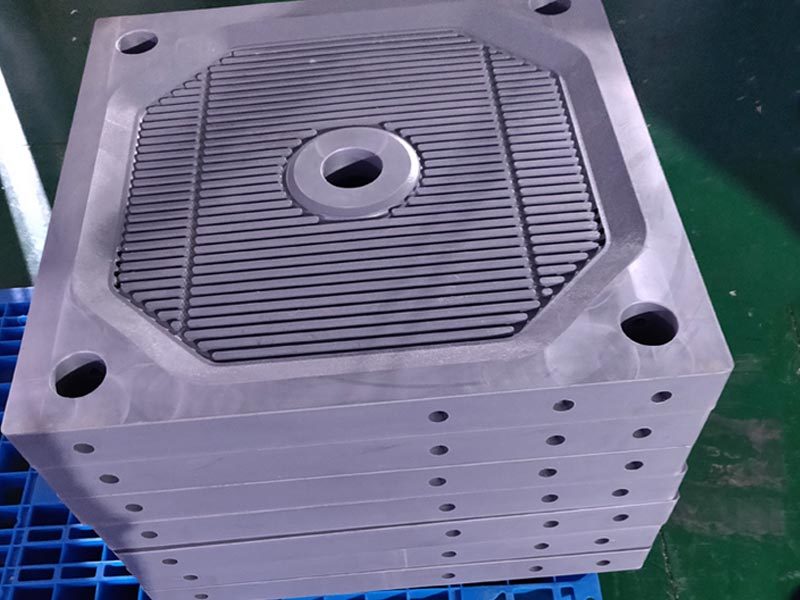

The design of **880 filter plates** is central to their functionality and efficiency. These plates are typically made from high-quality materials that resist corrosion and wear, ensuring longevity even under demanding conditions.

Key Features of 880 Filter Plates

1. **Durability**: Constructed from robust materials that withstand high pressures and temperatures.

2. **Optimal Filtration Area**: Engineered to maximize the surface area, allowing for improved flow rates and reduced clogging.

3. **Versatile Size Options**: Available in various dimensions to fit different filtration systems.

4. **Easy Maintenance**: Designed for simple installation and removal, facilitating quick maintenance and replacement.

Advantages of Using 880 Filter Plates

The implementation of **880 filter plates** offers numerous benefits that can significantly improve filtration efficiency.

Enhanced Filtration Efficiency

One of the primary advantages is the enhancement of filtration efficiency. The unique design minimizes resistance during fluid flow, allowing for higher throughput and reduced energy consumption.

Cost-Effectiveness

By improving efficiency and reducing operational costs, **880 filter plates** contribute to significant savings over time. Their durability also means fewer replacements, further decreasing long-term expenses.

Reduced Downtime

With their easy maintenance features, downtime is minimized. This is particularly beneficial in high-demand industrial settings where every minute counts.

Applications of 880 Filter Plates

**880 filter plates** are versatile components used across various industries. Their adaptability makes them suitable for a wide range of applications.

Water Treatment

In water treatment facilities, **880 filter plates** are employed to remove impurities from potable water, ensuring compliance with health standards.

Chemical Processing

The chemical industry utilizes these plates for separating solids from liquids, a common requirement in the production of chemicals and pharmaceuticals.

Food and Beverage Sector

In the food industry, filtration is critical to eliminate contaminants that could compromise product quality. **880 filter plates** help achieve high standards of safety and quality.

Maintenance and Care for Optimal Performance

Maintaining **880 filter plates** is essential to ensure optimal performance and longevity. Regular inspection and cleaning are recommended practices.

Best Practices for Maintenance

1. **Regular Inspections**: Check for wear and tear to identify potential issues early.

2. **Cleaning Protocols**: Depending on the application, establish a cleaning schedule to prevent clogging and maintain flow rates.

3. **Replacement Guidelines**: Understand when to replace filter plates based on operational demands and wear patterns.

Case Studies and Performance Analysis

Real-world examples highlight the impact of **880 filter plates** on filtration performance. Several case studies indicate improvements in efficiency and reduction in operational costs.

Case Study: Chemical Processing Plant

A chemical processing plant implemented **880 filter plates** into their filtration system, resulting in a 30% increase in throughput and a significant decrease in energy consumption.

Case Study: Wastewater Treatment Facility

In a wastewater treatment facility, the introduction of these filter plates led to improved contaminant removal rates, ensuring compliance with environmental regulations while reducing operational costs.

The Future of Filtration Technology

As industries continue to evolve, the demand for more efficient filtration systems will grow. Innovations in materials and design will likely shape the next generation of **880 filter plates**.

Emerging Trends

1. **Smart Filtration Systems**: The integration of IoT technology for real-time monitoring and optimization.

2. **Sustainable Materials**: A shift towards eco-friendly materials in the production of filter plates.

3. **Advanced Filtration Techniques**: Development of hybrid systems that combine various filtration methods for enhanced performance.

Conclusion

**880 filter plates** are revolutionizing the efficiency of filtration systems across various industries. Their innovative design, coupled with numerous advantages, makes them an essential component for maintaining high operational standards. By adopting these filter plates, industries can achieve significant cost savings, improved compliance with regulations, and enhanced product quality. Embracing the advancements in filtration technology will not only benefit individual enterprises but also contribute to broader environmental sustainability goals.

FAQs about 880 Filter Plates

1. What are 880 filter plates used for?

880 filter plates are primarily used in filtration systems to separate solids from liquids or gases in various industrial applications.

2. How do 880 filter plates improve efficiency?

Their design maximizes filtration area and minimizes flow resistance, leading to increased throughput and reduced energy consumption.

3. Are 880 filter plates easy to maintain?

Yes, they are designed for easy installation and removal, facilitating straightforward maintenance and cleaning.

4. What industries benefit from using 880 filter plates?

Industries such as chemical processing, water treatment, and food and beverage significantly benefit from the use of 880 filter plates.

5. How do I know when to replace my filter plates?

Regular inspections will help identify wear and tear. Replace the plates based on performance decline or operational demands.

Related News