Understanding the Importance of 800 x 800 Filter Plates in Industrial Filtration Systems

Release time:

2025-03-27

In the realm of industrial filtration, **800 x 800 filter plates** are essential components that contribute significantly to the efficiency and effectiveness of various filtration systems. Designed to accommodate a wide range of filtration applications, these plates are well-regarded for their dimensions, which often optimize space and enhance the filtration process. Filter plates, particularly t

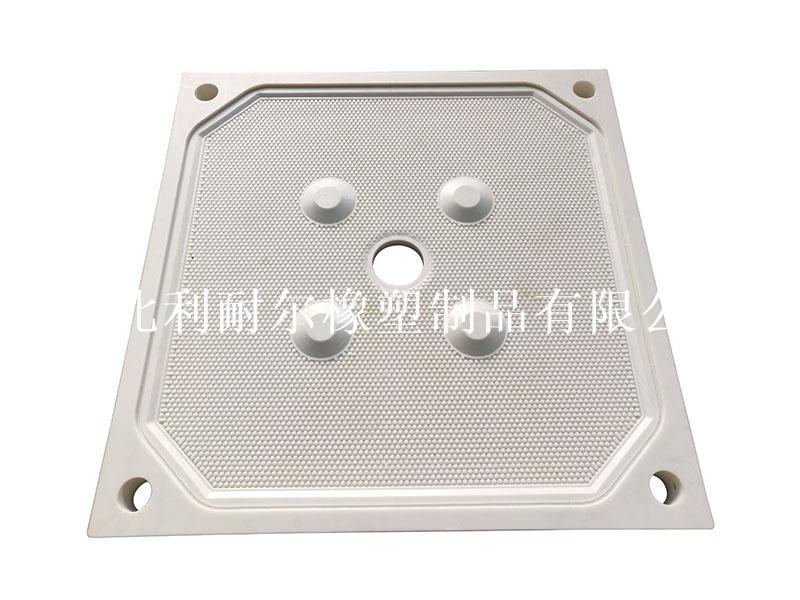

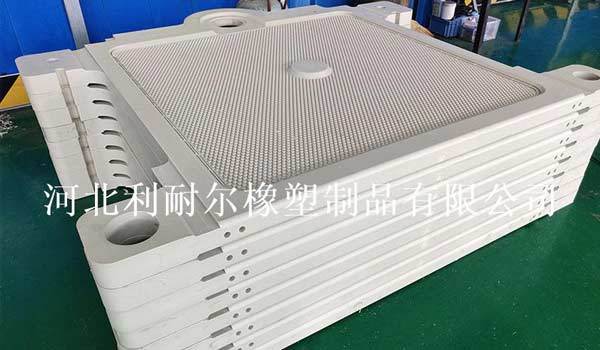

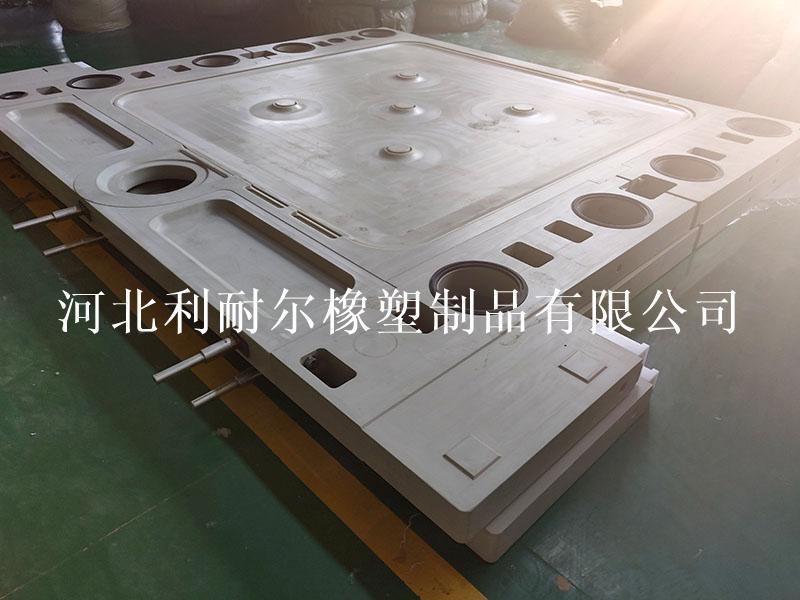

In the realm of industrial filtration, **800 x 800 filter plates** are essential components that contribute significantly to the efficiency and effectiveness of various filtration systems. Designed to accommodate a wide range of filtration applications, these plates are well-regarded for their dimensions, which often optimize space and enhance the filtration process.

Filter plates, particularly those measuring 800 x 800 millimeters, are commonly used in industries such as pharmaceuticals, food and beverage, wastewater treatment, and chemical processing. Their large surface area allows for greater throughput of materials, which can be critical in high-volume operations. The choice of material for these filter plates is also crucial, as it must withstand the specific chemical and mechanical demands of each application.

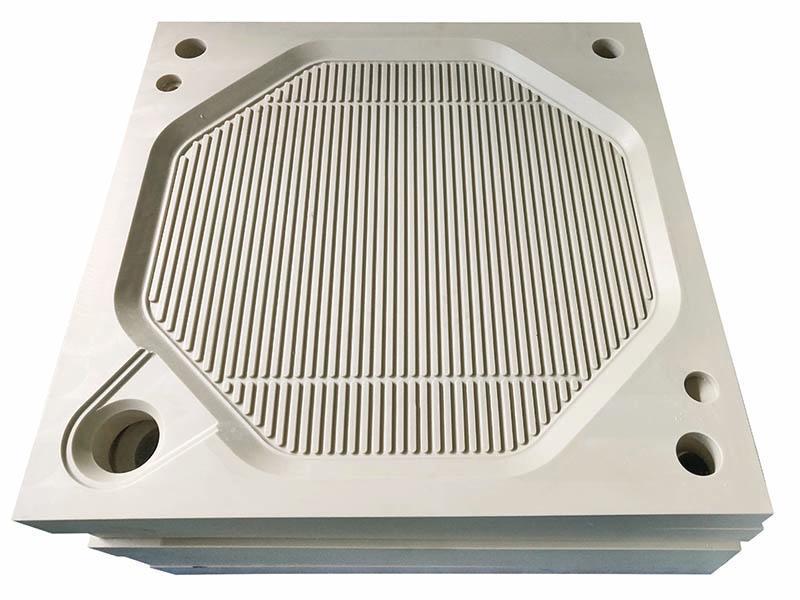

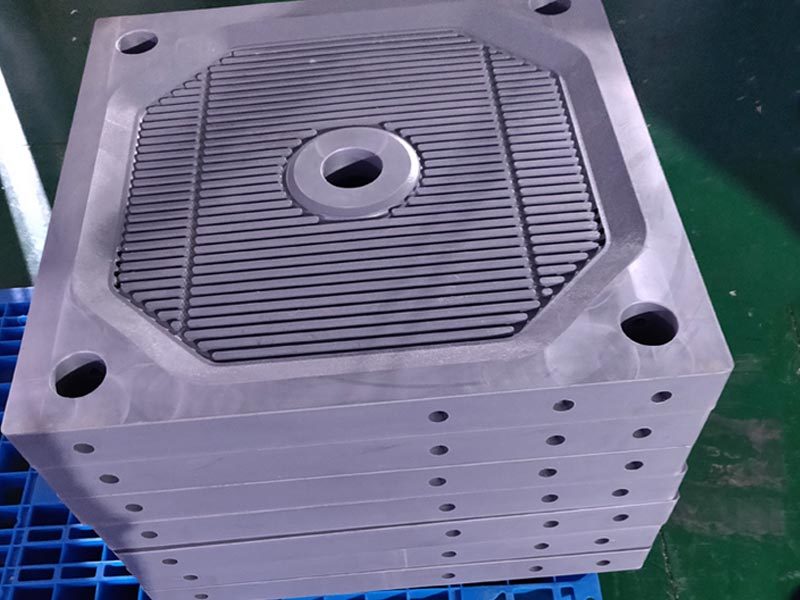

The primary function of an 800 x 800 filter plate is to act as a barrier that separates solids from liquids, facilitating the purification process. This is achieved through various filtering mechanisms, including gravity, pressure, and vacuum filtration. The design of these filter plates allows for efficient liquid flow while capturing particulate matter, ensuring that the final output meets the required purity standards.

Moreover, the maintenance of filter plates is an important consideration for industrial operations. Regular cleaning and inspection can help extend the life of the filter plates and maintain optimal filtration performance. Users need to be aware of the signs indicating that a filter plate may require replacement, such as reduced flow rates or changes in the quality of the filtered output.

In addition to their practical applications, 800 x 800 filter plates can also be customized to meet specific needs. Different porosities and materials can be selected based on the type of substances being filtered, allowing for tailored solutions that enhance efficiency and effectiveness. When integrating these filter plates into filtration systems, it’s essential for professionals to carefully assess the operational requirements and select the appropriate specifications.

Overall, the role of **800 x 800 filter plates** in industrial filtration cannot be overstated. Their ability to optimize performance and adapt to various applications makes them an indispensable element in maintaining the quality and safety of industrial processes. Understanding their importance and functionality will enable professionals to make informed decisions that enhance operational efficiency and ensure compliance with industry standards.

Filter plates, particularly those measuring 800 x 800 millimeters, are commonly used in industries such as pharmaceuticals, food and beverage, wastewater treatment, and chemical processing. Their large surface area allows for greater throughput of materials, which can be critical in high-volume operations. The choice of material for these filter plates is also crucial, as it must withstand the specific chemical and mechanical demands of each application.

The primary function of an 800 x 800 filter plate is to act as a barrier that separates solids from liquids, facilitating the purification process. This is achieved through various filtering mechanisms, including gravity, pressure, and vacuum filtration. The design of these filter plates allows for efficient liquid flow while capturing particulate matter, ensuring that the final output meets the required purity standards.

Moreover, the maintenance of filter plates is an important consideration for industrial operations. Regular cleaning and inspection can help extend the life of the filter plates and maintain optimal filtration performance. Users need to be aware of the signs indicating that a filter plate may require replacement, such as reduced flow rates or changes in the quality of the filtered output.

In addition to their practical applications, 800 x 800 filter plates can also be customized to meet specific needs. Different porosities and materials can be selected based on the type of substances being filtered, allowing for tailored solutions that enhance efficiency and effectiveness. When integrating these filter plates into filtration systems, it’s essential for professionals to carefully assess the operational requirements and select the appropriate specifications.

Overall, the role of **800 x 800 filter plates** in industrial filtration cannot be overstated. Their ability to optimize performance and adapt to various applications makes them an indispensable element in maintaining the quality and safety of industrial processes. Understanding their importance and functionality will enable professionals to make informed decisions that enhance operational efficiency and ensure compliance with industry standards.

Related News