Exploring the Versatility and Importance of 1000 Diaphragm Plates in Industrial Filtration

Release time:

2025-03-11

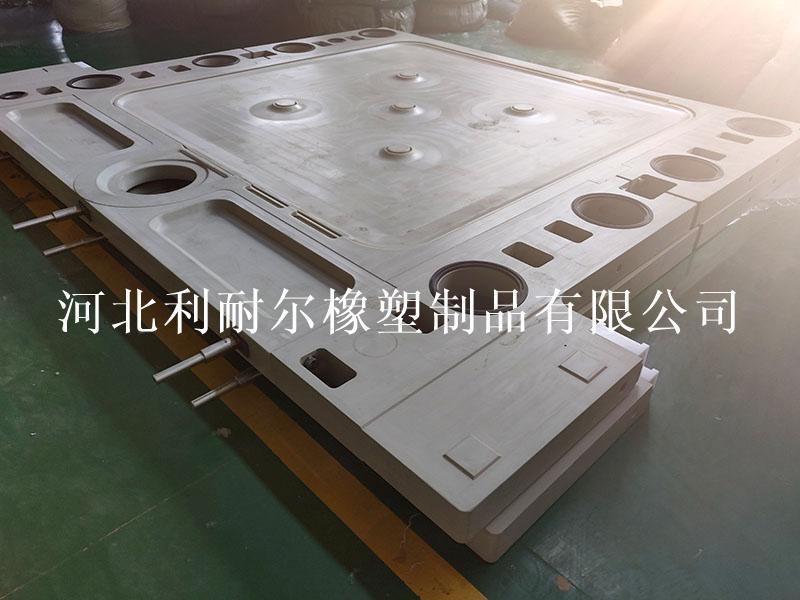

In the industrial filtration sector, components such as the 1000 diaphragm plate are essential for achieving optimal performance and reliability in filtration systems. Understanding their functionality and applications can greatly benefit professionals in industries ranging from chemical processing to food and beverage production. A diaphragm plate is a crucial part of filtration equipment, respon

In the industrial filtration sector, components such as the 1000 diaphragm plate are essential for achieving optimal performance and reliability in filtration systems. Understanding their functionality and applications can greatly benefit professionals in industries ranging from chemical processing to food and beverage production.

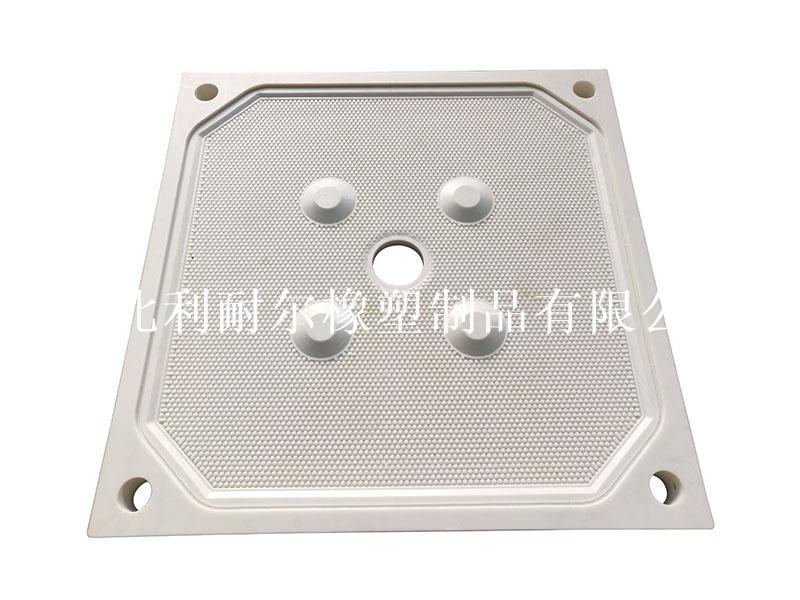

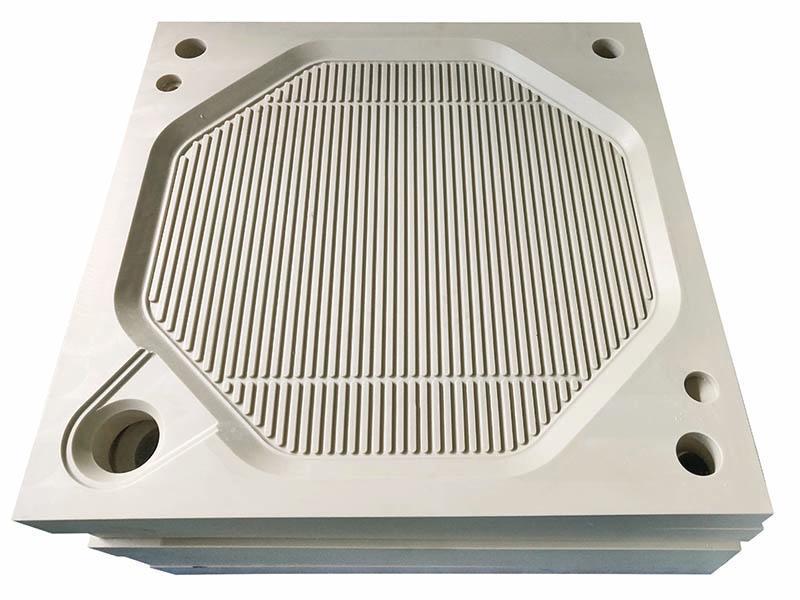

A diaphragm plate is a crucial part of filtration equipment, responsible for separating contaminants from liquids or gases. The "1000" designation often refers to a specific design or size, potentially indicating its thickness, diameter, or operational capacity. These plates are engineered to withstand high pressures and temperatures, making them suitable for harsh industrial environments.

One of the primary advantages of using a 1000 diaphragm plate is its efficiency in filtration processes. The design of these plates allows for a high surface area, enabling them to capture more particulates compared to traditional filtration methods. This increases the overall effectiveness of the filtration system, leading to cleaner output and reduced operational downtime due to maintenance or replacement needs.

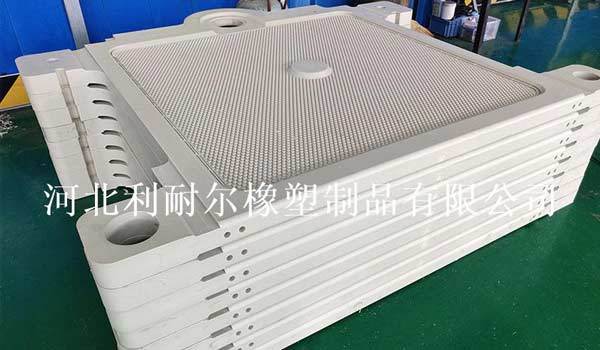

Additionally, 1000 diaphragm plates are often made from durable materials that ensure longevity and resistance to chemical corrosion. This durability is critical in industrial settings where exposure to aggressive substances can compromise the integrity of less robust filtration components. By utilizing these diaphragm plates, industries can enhance their filtration systems' reliability, ultimately contributing to improved product quality and safety.

Moreover, the versatility of 1000 diaphragm plates allows them to be used in various applications, including liquid filtration, air purification, and even in the pharmaceutical industry for sterile processing. Their adaptability makes them a key component in ensuring compliance with industry standards and regulations, particularly in sectors where contamination control is paramount.

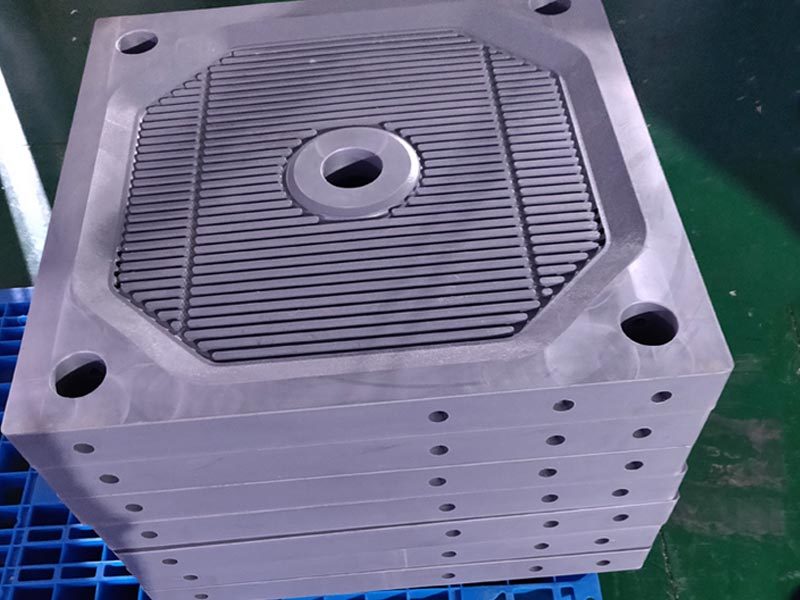

When selecting a diaphragm plate, it is important to consider factors such as compatibility with the specific fluids or gases being filtered, as well as the operational parameters of the filtration system. Engaging with a knowledgeable supplier can help ensure that the chosen diaphragm plate meets the required specifications and enhances the system’s overall performance.

In conclusion, the 1000 diaphragm plate plays an integral role in industrial filtration processes, offering numerous benefits, including enhanced efficiency, durability, and versatility. By understanding the importance of this component, professionals can make informed decisions that lead to better filtration outcomes and improved operational performance across various industries.

A diaphragm plate is a crucial part of filtration equipment, responsible for separating contaminants from liquids or gases. The "1000" designation often refers to a specific design or size, potentially indicating its thickness, diameter, or operational capacity. These plates are engineered to withstand high pressures and temperatures, making them suitable for harsh industrial environments.

One of the primary advantages of using a 1000 diaphragm plate is its efficiency in filtration processes. The design of these plates allows for a high surface area, enabling them to capture more particulates compared to traditional filtration methods. This increases the overall effectiveness of the filtration system, leading to cleaner output and reduced operational downtime due to maintenance or replacement needs.

Additionally, 1000 diaphragm plates are often made from durable materials that ensure longevity and resistance to chemical corrosion. This durability is critical in industrial settings where exposure to aggressive substances can compromise the integrity of less robust filtration components. By utilizing these diaphragm plates, industries can enhance their filtration systems' reliability, ultimately contributing to improved product quality and safety.

Moreover, the versatility of 1000 diaphragm plates allows them to be used in various applications, including liquid filtration, air purification, and even in the pharmaceutical industry for sterile processing. Their adaptability makes them a key component in ensuring compliance with industry standards and regulations, particularly in sectors where contamination control is paramount.

When selecting a diaphragm plate, it is important to consider factors such as compatibility with the specific fluids or gases being filtered, as well as the operational parameters of the filtration system. Engaging with a knowledgeable supplier can help ensure that the chosen diaphragm plate meets the required specifications and enhances the system’s overall performance.

In conclusion, the 1000 diaphragm plate plays an integral role in industrial filtration processes, offering numerous benefits, including enhanced efficiency, durability, and versatility. By understanding the importance of this component, professionals can make informed decisions that lead to better filtration outcomes and improved operational performance across various industries.

Related News