Understanding the Role of the 1500 Diaphragm Plate in Industrial Filtration

Release time:

2025-03-03

The 1500 diaphragm plate plays a crucial role in numerous industrial filtration processes, serving as an essential component in various filtration systems. Its primary function is to facilitate the separation of solid particles from liquids or gases, effectively enhancing the overall efficiency and effectiveness of the filtration process. One of the key advantages of the 1500 diaphragm plate is it

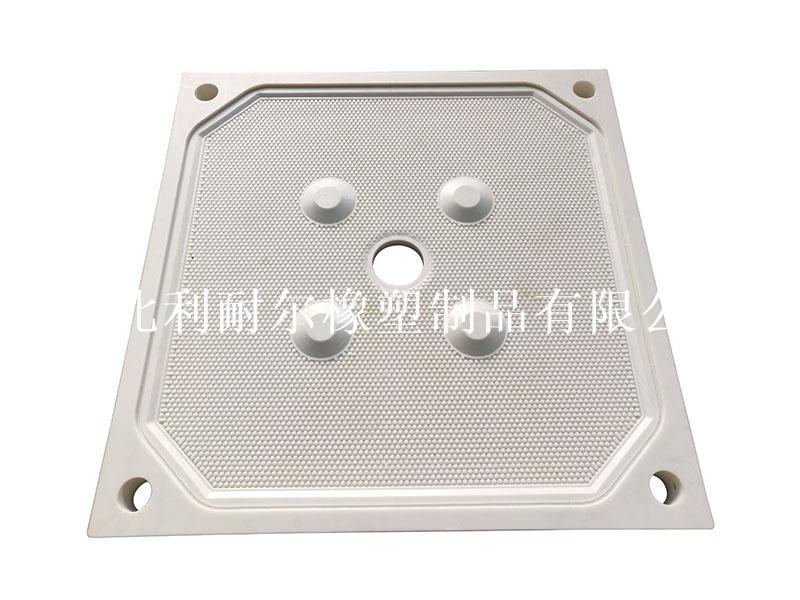

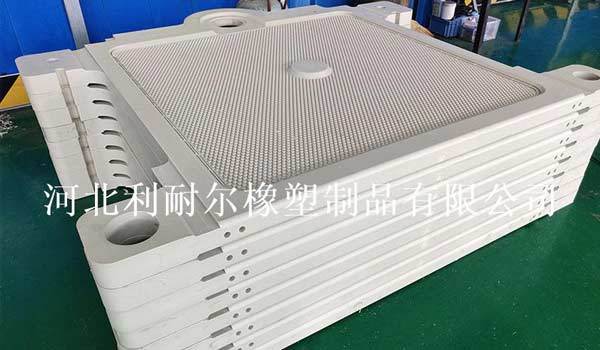

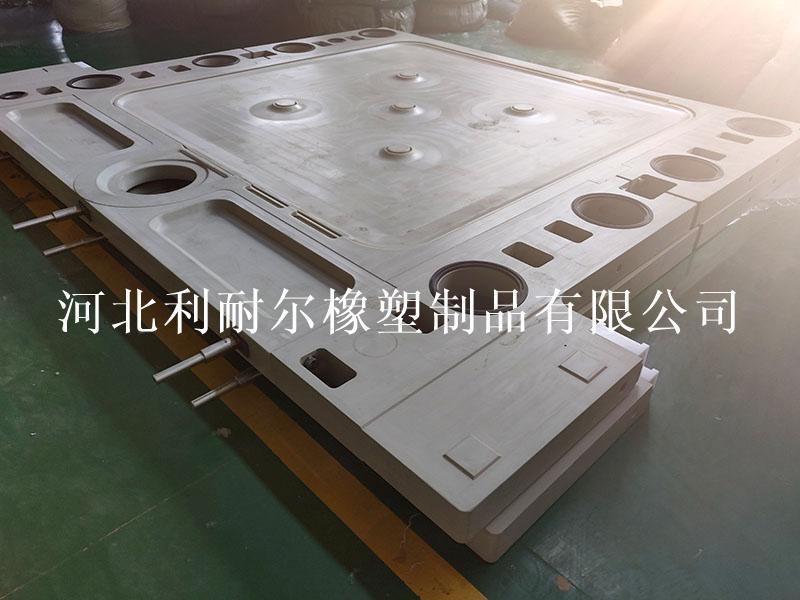

The 1500 diaphragm plate plays a crucial role in numerous industrial filtration processes, serving as an essential component in various filtration systems. Its primary function is to facilitate the separation of solid particles from liquids or gases, effectively enhancing the overall efficiency and effectiveness of the filtration process.

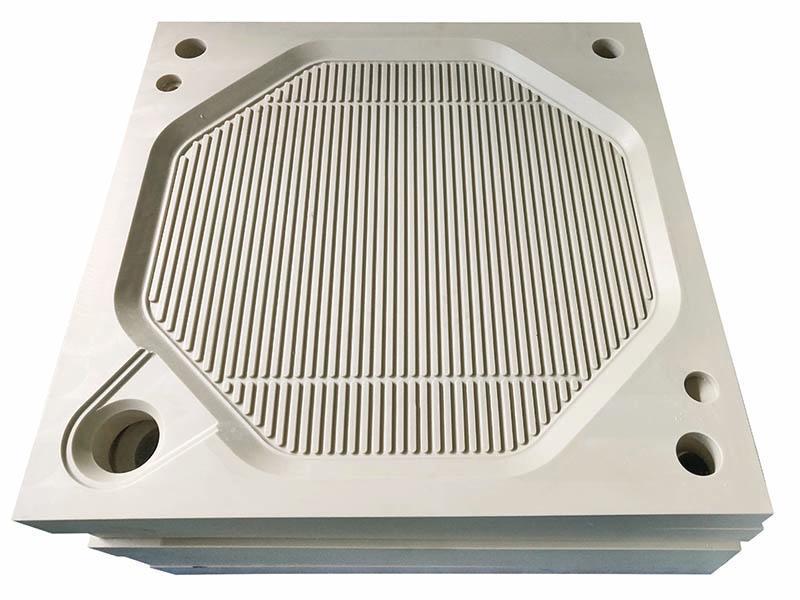

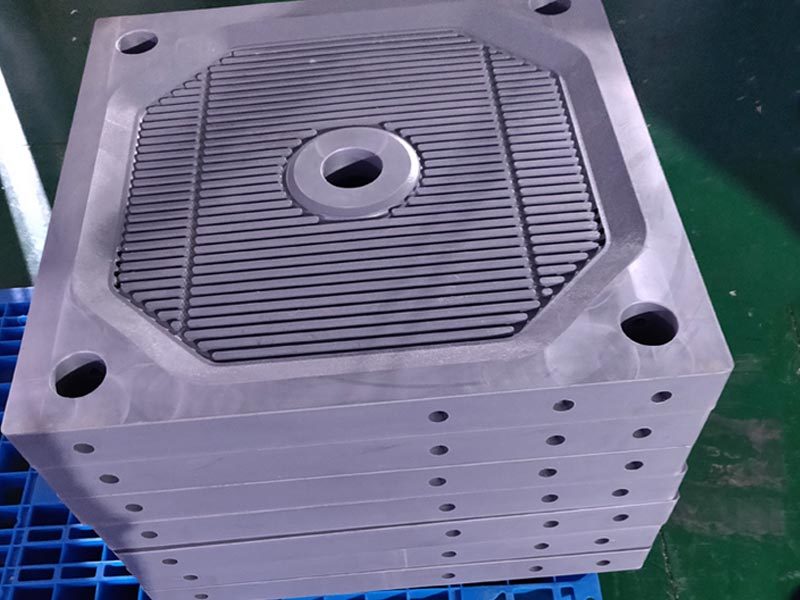

One of the key advantages of the 1500 diaphragm plate is its robust design, which enables it to withstand high pressures and corrosive environments. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance, ultimately translating into cost savings for industrial operators. The diaphragm plate's material composition is specifically chosen to resist wear and tear, making it suitable for filtering abrasive substances.

In filtration applications, the 1500 diaphragm plate acts as a barrier, allowing only the desired fluid to pass through while trapping contaminants. This selective permeability is crucial for maintaining the quality of the end product, whether it is a liquid or gas. The diaphragm's design can be tailored to meet specific filtration needs, including pore size and flow rates, making it highly versatile for various industries, including chemical processing, water treatment, and food and beverage production.

Another significant feature of the 1500 diaphragm plate is its ability to operate efficiently in automated systems. Integration with control systems allows for real-time monitoring and adjustment of filtration parameters, enhancing operational efficiency. This responsiveness is particularly important in large-scale industrial settings where consistent quality and throughput are paramount.

Furthermore, the 1500 diaphragm plate contributes to environmental sustainability. By improving filtration efficiency, it helps reduce waste and energy consumption in filtration processes. Companies are increasingly focusing on green practices, and employing efficient filtration solutions like the 1500 diaphragm plate can significantly impact overall environmental performance.

When selecting a diaphragm plate for industrial applications, professionals should consider factors such as compatibility with the specific fluids being filtered, the operational environment, and the required filtration efficiency. Understanding these parameters will ensure that the chosen diaphragm plate meets the operational demands while optimizing performance.

In summary, the 1500 diaphragm plate is an indispensable component in the field of industrial filtration. Its robust design, efficiency in separating contaminants, and adaptability to automation make it a vital asset for improving filtration processes in various industries. By choosing the right diaphragm plate, companies can enhance operational efficiency, ensure product quality, and contribute to sustainable practices.

One of the key advantages of the 1500 diaphragm plate is its robust design, which enables it to withstand high pressures and corrosive environments. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance, ultimately translating into cost savings for industrial operators. The diaphragm plate's material composition is specifically chosen to resist wear and tear, making it suitable for filtering abrasive substances.

In filtration applications, the 1500 diaphragm plate acts as a barrier, allowing only the desired fluid to pass through while trapping contaminants. This selective permeability is crucial for maintaining the quality of the end product, whether it is a liquid or gas. The diaphragm's design can be tailored to meet specific filtration needs, including pore size and flow rates, making it highly versatile for various industries, including chemical processing, water treatment, and food and beverage production.

Another significant feature of the 1500 diaphragm plate is its ability to operate efficiently in automated systems. Integration with control systems allows for real-time monitoring and adjustment of filtration parameters, enhancing operational efficiency. This responsiveness is particularly important in large-scale industrial settings where consistent quality and throughput are paramount.

Furthermore, the 1500 diaphragm plate contributes to environmental sustainability. By improving filtration efficiency, it helps reduce waste and energy consumption in filtration processes. Companies are increasingly focusing on green practices, and employing efficient filtration solutions like the 1500 diaphragm plate can significantly impact overall environmental performance.

When selecting a diaphragm plate for industrial applications, professionals should consider factors such as compatibility with the specific fluids being filtered, the operational environment, and the required filtration efficiency. Understanding these parameters will ensure that the chosen diaphragm plate meets the operational demands while optimizing performance.

In summary, the 1500 diaphragm plate is an indispensable component in the field of industrial filtration. Its robust design, efficiency in separating contaminants, and adaptability to automation make it a vital asset for improving filtration processes in various industries. By choosing the right diaphragm plate, companies can enhance operational efficiency, ensure product quality, and contribute to sustainable practices.

Related News