Why the 1200 Diaphragm Plate is Essential for Efficient Filtering

Release time:

2025-02-27

Why the 1200 Diaphragm Plate is Essential for Efficient Filtering Table of Contents 1. Introduction to Filtration Technology 2. Understanding the Diaphragm Plate 3. Key Features of the 1200 Diaphragm Plate 4. Advantages of Using the 1200 Diaphragm Plate 5. Applications of the 1200 Diaphragm Plate in Various Industries 6. How the 1200 Diaphragm Plate Enhances Filtration Efficiency 6

Why the 1200 Diaphragm Plate is Essential for Efficient Filtering

Table of Contents

1. Introduction to Filtration Technology

2. Understanding the Diaphragm Plate

3. Key Features of the 1200 Diaphragm Plate

4. Advantages of Using the 1200 Diaphragm Plate

5. Applications of the 1200 Diaphragm Plate in Various Industries

6. How the 1200 Diaphragm Plate Enhances Filtration Efficiency

6.1 Improved Liquid Flow Rates

6.2 Enhanced Solid Removal

6.3 Reliability and Durability

7. Maintenance Tips for the 1200 Diaphragm Plate

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Filtration Technology

In various industrial processes, **filtration technology** plays a critical role in ensuring the purity and quality of products. Filtration is the process of separating solids from liquids or gases using a filter medium. The effectiveness of this process depends on the quality of the filtration equipment, including components such as diaphragm plates. Among these, the **1200 Diaphragm Plate** stands out as a vital component that significantly enhances filtering efficiency across multiple applications.

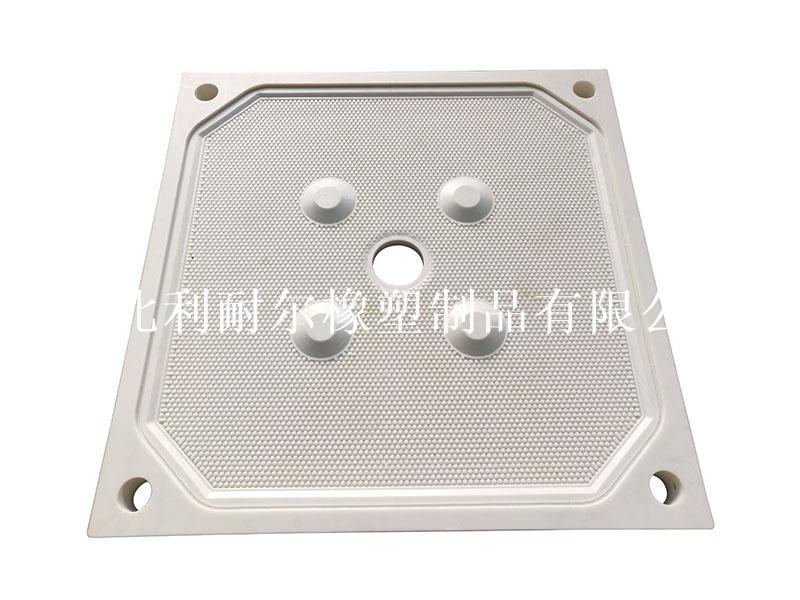

2. Understanding the Diaphragm Plate

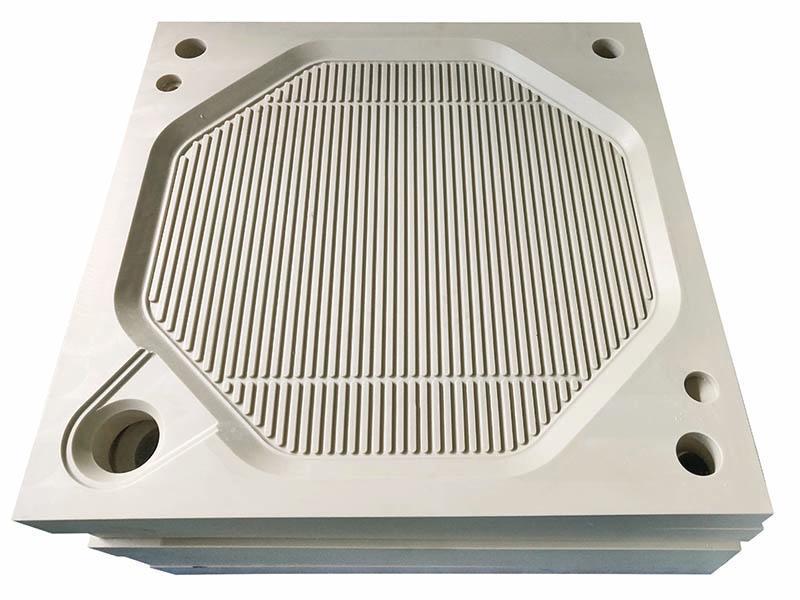

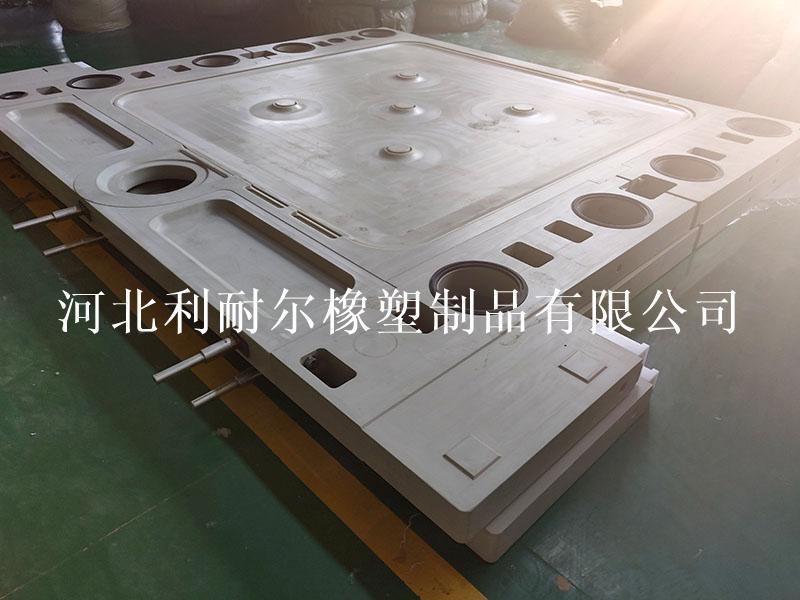

A **diaphragm plate** is a specialized component used in filtration systems, particularly in **plate and frame filters**. This technology employs a series of plates that hold filter media in place, allowing for efficient separation of solids from liquids. The diaphragm plate's design facilitates the even distribution of pressure and flow across the filtration surface, enhancing the overall efficiency of the filtering process.

3. Key Features of the 1200 Diaphragm Plate

The **1200 Diaphragm Plate** is engineered with several key features that make it indispensable in filtration applications:

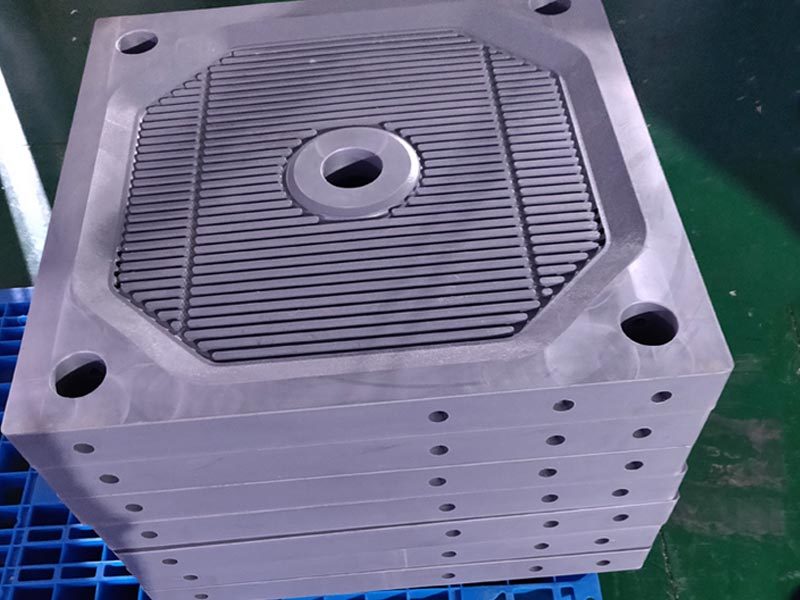

1. **Material Composition**: Constructed from high-quality, corrosion-resistant materials, this diaphragm plate ensures longevity and reliability even in harsh environments.

2. **Design Efficiency**: Its innovative design promotes optimal flow dynamics, which reduces clogging and increases throughput.

3. **Versatility**: Suitable for various industries, including chemical, pharmaceutical, and food processing, the 1200 diaphragm plate adapts to different filtering needs.

4. Advantages of Using the 1200 Diaphragm Plate

Adopting the **1200 Diaphragm Plate** in filtration systems offers numerous advantages:

- **Increased Filtration Rates**: By optimizing flow distribution, it allows for quicker processing times and higher output.

- **Reduced Maintenance Costs**: With its robust design, the diaphragm plate requires less frequent replacement, thereby lowering maintenance expenses.

- **Improved Product Quality**: Enhanced filtration leads to better quality end products, free from contaminants that could compromise integrity.

5. Applications of the 1200 Diaphragm Plate in Various Industries

The **1200 Diaphragm Plate** finds applications in a multitude of sectors, including:

- **Pharmaceutical Manufacturing**: Ensures sterile processing and high product purity by effectively removing contaminants.

- **Food and Beverage Industry**: Utilized for filtering juices, wines, and oils to achieve clear and pure products while maintaining flavor integrity.

- **Chemical Processing**: Supports the filtration of various chemicals, ensuring that the final products meet stringent quality standards.

6. How the 1200 Diaphragm Plate Enhances Filtration Efficiency

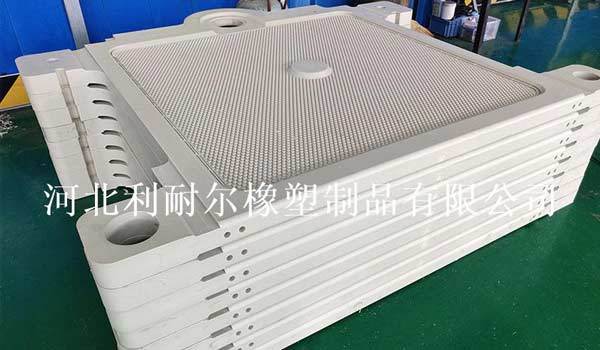

The **1200 Diaphragm Plate** is crucial for improving filtration efficiency through several mechanisms:

6.1 Improved Liquid Flow Rates

The design of the 1200 Diaphragm Plate allows for **optimized liquid flow**, minimizing resistance and maximizing throughput. This feature translates to faster processing times, which is essential in high-demand environments.

6.2 Enhanced Solid Removal

With its precise filtration capabilities, the diaphragm plate effectively captures even the smallest particles, ensuring that the final product is free from unwanted solids. This is paramount in industries where product purity is non-negotiable.

6.3 Reliability and Durability

Constructed from durable materials, the 1200 Diaphragm Plate withstands the rigors of continuous operation. Its resilience against wear and tear translates to less downtime and increased operational efficiency.

7. Maintenance Tips for the 1200 Diaphragm Plate

To ensure the longevity and optimal performance of the **1200 Diaphragm Plate**, consider the following maintenance tips:

- **Regular Inspections**: Conduct routine checks for signs of wear and tear. Early detection of issues can prevent costly repairs down the line.

- **Proper Cleaning**: After each use, clean the diaphragm plate thoroughly to remove any residual particles that could affect future filtration cycles.

- **Follow Manufacturer Guidelines**: Adhering to the manufacturer's maintenance recommendations is crucial for ensuring the diaphragm plate's performance and lifespan.

8. Frequently Asked Questions (FAQs)

What is the purpose of a diaphragm plate in filtration systems?

The diaphragm plate serves as a structural element that supports filter media, facilitating the separation of solids from liquids efficiently.

How does the 1200 Diaphragm Plate improve filtration efficiency?

Its design optimizes flow dynamics, enhances solid removal, and increases processing speeds, leading to significantly improved filtration efficiency.

Can the 1200 Diaphragm Plate be used in various industries?

Yes, it is versatile and applicable in industries such as pharmaceuticals, food processing, and chemical manufacturing.

What materials are used in the construction of the 1200 Diaphragm Plate?

It is made from high-quality, corrosion-resistant materials designed to withstand harsh operational environments.

How often should the 1200 Diaphragm Plate be replaced?

Replacement frequency depends on usage conditions, but regular inspections and maintenance can extend its lifespan significantly.

9. Conclusion

In summary, the **1200 Diaphragm Plate** is an essential component for achieving efficient filtering across various industries. Its innovative design, combined with durable materials, ensures that it meets the rigorous demands of modern filtration processes. By incorporating this diaphragm plate into your system, you can enhance filtration efficiency, lower maintenance costs, and improve product quality. Investing in the 1200 Diaphragm Plate is a strategic decision that pays dividends in operational efficiency and product excellence.

Related News