Exploring Different Types of Filter Press Diaphragms Available Today

Release time:

2025-02-19

Exploring Different Types of Filter Press Diaphragms Available Today Table of Contents 1. Introduction to Filter Press Diaphragms 2. What is a Filter Press Diaphragm? 3. Types of Filter Press Diaphragms 3.1 Rubber Diaphragms 3.2 Polypropylene Diaphragms 3.3 Teflon Diaphragms 3.4 Nitrile Diaphragms 3.5 Silicone Diaphr

Exploring Different Types of Filter Press Diaphragms Available Today

Table of Contents

- 1. Introduction to Filter Press Diaphragms

- 2. What is a Filter Press Diaphragm?

- 3. Types of Filter Press Diaphragms

- 3.1 Rubber Diaphragms

- 3.2 Polypropylene Diaphragms

- 3.3 Teflon Diaphragms

- 3.4 Nitrile Diaphragms

- 3.5 Silicone Diaphragms

- 4. Benefits of Using Filter Press Diaphragms

- 5. Applications of Filter Press Diaphragms

- 6. How to Choose the Right Diaphragm for Your Needs

- 7. Maintenance of Filter Press Diaphragms

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Introduction to Filter Press Diaphragms

In the realm of chemical engineering and plastic manufacturing, **filter press diaphragms** play a critical role. They are essential components in the separation of solids from liquids, ensuring efficient filtration in various applications. With the growing demand for high-quality filtration systems, understanding the different types of diaphragms available is crucial for industry professionals. This article serves as a comprehensive guide, exploring the various types of filter press diaphragms and their applications, benefits, and maintenance.

2. What is a Filter Press Diaphragm?

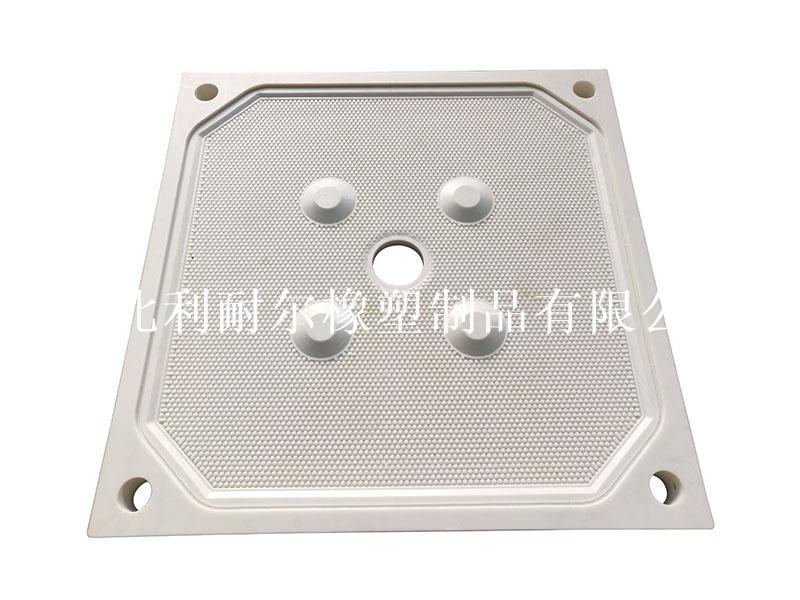

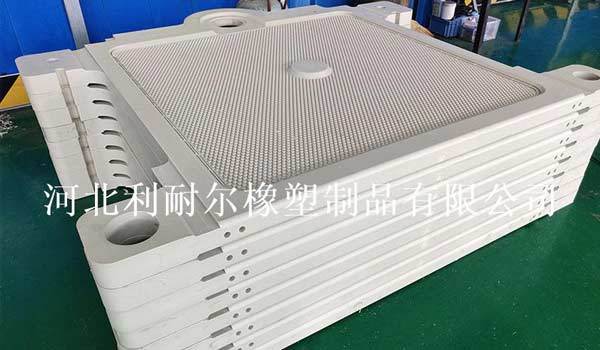

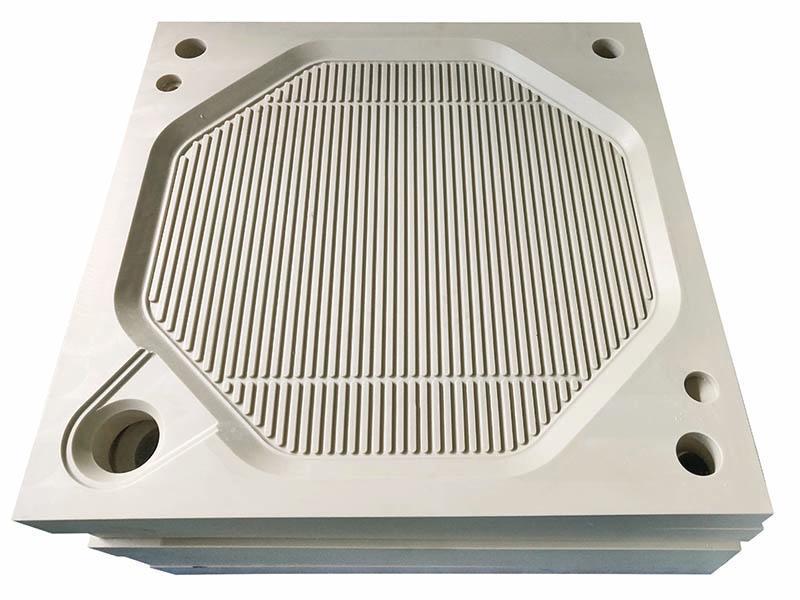

A **filter press diaphragm** is a flexible membrane that is utilized in filter press systems to separate solid and liquid components in a slurry. The diaphragm is positioned between the filter plates and plays a pivotal role in the filtration process. When the press is activated, hydraulic pressure forces the diaphragm to expand, pressing the slurry against the filter media, which results in the formation of a cake of solids. This process is essential for various industrial applications, including wastewater treatment, mining, and food processing.

3. Types of Filter Press Diaphragms

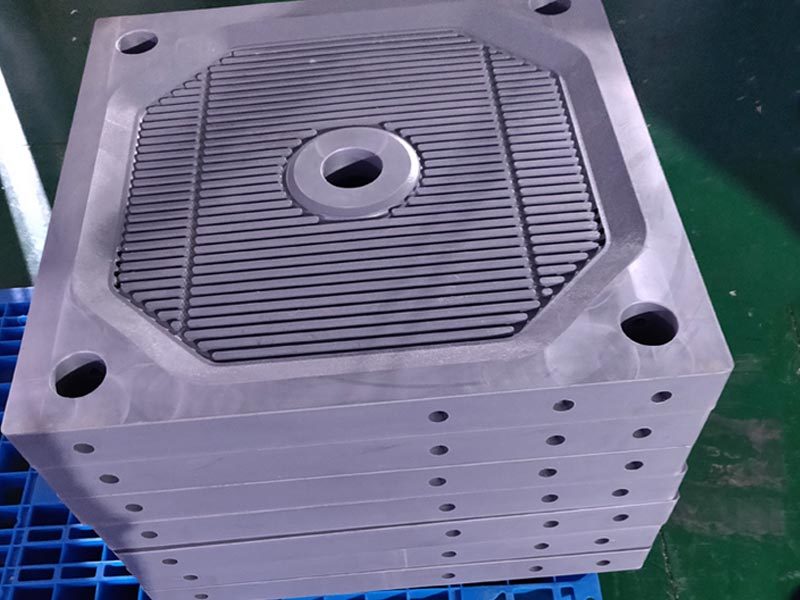

Filter press diaphragms come in various materials, each tailored for specific applications. Understanding these materials can help in selecting the right diaphragm for your needs.

3.1 Rubber Diaphragms

**Rubber diaphragms** are highly flexible and provide excellent resistance to wear and tear. They are ideal for applications that require high elasticity and can withstand harsh chemicals. Rubber diaphragms are often used in industries such as wastewater treatment, where durability is essential.

3.2 Polypropylene Diaphragms

**Polypropylene diaphragms** are lightweight and corrosion-resistant, making them a popular choice in many chemical processes. They are suitable for applications involving acidic or alkaline solutions. Their chemical resistance ensures a longer lifespan and reduced maintenance costs.

3.3 Teflon Diaphragms

**Teflon diaphragms** are known for their exceptional chemical resistance and non-stick properties. They are ideal for applications involving aggressive chemicals or solvents. Teflon is often the preferred choice in pharmaceutical and food processing industries due to its inert nature.

3.4 Nitrile Diaphragms

**Nitrile diaphragms** offer excellent resistance to petroleum-based oils and fuels. They are widely used in applications requiring resilience against oils and greases. Their durability makes them suitable for industrial environments that demand reliable performance.

3.5 Silicone Diaphragms

**Silicone diaphragms** are known for their flexibility and high-temperature resistance. They are suitable for applications that require sterilization, such as in the food and pharmaceutical sectors. Silicone is also compliant with FDA regulations, ensuring safety in food processing.

4. Benefits of Using Filter Press Diaphragms

The use of filter press diaphragms offers numerous advantages for industrial filtration processes:

- **Efficiency**: Diaphragms enhance the filtration process by ensuring maximum solid-liquid separation, reducing waste and increasing throughput.

- **Versatility**: With different materials available, diaphragms can be tailored for various applications, accommodating a wide range of chemical properties.

- **Cost-Effectiveness**: The durability of modern diaphragms leads to reduced maintenance and replacement costs, contributing to overall operational cost savings.

- **Improved Quality**: Utilizing the appropriate diaphragm can significantly enhance the quality of the final product by ensuring consistent filtration.

5. Applications of Filter Press Diaphragms

Filter press diaphragms are utilized across various industries, showcasing their versatility:

- **Wastewater Treatment**: In water treatment facilities, these diaphragms are crucial for separating solids from water, ensuring compliance with environmental regulations.

- **Mining**: In mineral processing, filter press diaphragms help in dewatering slurries, improving the recovery of valuable minerals.

- **Food Processing**: Used in the production of juices, oils, and other consumables, these diaphragms ensure that the final products meet hygiene and quality standards.

- **Pharmaceuticals**: In this sector, Teflon and silicone diaphragms are often employed due to their chemical inertness and ability to withstand sterilization processes.

6. How to Choose the Right Diaphragm for Your Needs

Selecting the right filter press diaphragm is vital for optimal performance. Here are key factors to consider:

1. **Chemical Compatibility**: Ensure the diaphragm material is compatible with the chemicals in your process to avoid degradation.

2. **Temperature and Pressure Requirements**: Assess the maximum temperature and pressure conditions to ensure the diaphragm can withstand operational demands.

3. **Flexibility and Strength**: Depending on the nature of the slurry, select a diaphragm that offers the right balance of flexibility and strength.

4. **Regulatory Compliance**: For industries like food and pharmaceuticals, ensure the material meets relevant safety and quality standards.

7. Maintenance of Filter Press Diaphragms

Proper maintenance is essential to extend the lifespan of filter press diaphragms:

- **Regular Inspection**: Inspect diaphragms for signs of wear and tear, including cracks and punctures, and replace them as needed.

- **Cleaning**: Ensure proper cleaning of the filter press system to prevent the accumulation of contaminants that may damage the diaphragm.

- **Operational Monitoring**: Keep an eye on pressure levels during operation to prevent overloading, which can lead to diaphragm failure.

8. Frequently Asked Questions (FAQs)

What is the lifespan of a filter press diaphragm?

The lifespan of a filter press diaphragm varies based on the material used and operational conditions, typically ranging from 1 to 5 years.

Can I use different types of diaphragms in the same filter press?

While it is technically possible to use different types of diaphragms, it is not advisable, as it may lead to inconsistent performance and increased wear.

How do I know when to replace a filter press diaphragm?

Signs that a diaphragm needs replacement include visible wear, reduced filtration efficiency, and increased leakage during operation.

Are there any environmental considerations when choosing a diaphragm material?

Yes, consider the environmental impact of the materials used, particularly in industries like food processing and pharmaceuticals, where regulatory standards may apply.

What are the costs associated with filter press diaphragms?

Costs can vary significantly based on the material and size of the diaphragm, ranging from a few hundred to several thousand dollars.

9. Conclusion

Understanding the various types of filter press diaphragms is crucial for any professional involved in industrial filtration processes. By recognizing the unique benefits and applications of each diaphragm type, you can make informed decisions that enhance filtration efficiency and product quality. Regular maintenance and careful selection based on operational needs will ensure that your filtration systems remain effective and reliable for years to come. Investing in the right filter press diaphragm is not just a matter of functionality; it is key to optimizing your industrial processes and safeguarding your operations against potential risks.

Related News