Maximize Efficiency: The Role of Filter Press Grilles in Chemical Processing

Release time:

2025-02-11

Maximize Efficiency: The Role of Filter Press Grilles in Chemical Processing Table of Contents 1. Introduction to Chemical Processing and Filter Press Grilles 2. Understanding Filter Press Grilles: Design and Functionality 2.1 What Are Filter Press Grilles? 2.2 Key Components of Filter Press Grilles 3. The Importance of Efficiency in Chemical Processing 4. How Filter Press Grilles Improve Operatio

Maximize Efficiency: The Role of Filter Press Grilles in Chemical Processing

Table of Contents

1. Introduction to Chemical Processing and Filter Press Grilles

2. Understanding Filter Press Grilles: Design and Functionality

2.1 What Are Filter Press Grilles?

2.2 Key Components of Filter Press Grilles

3. The Importance of Efficiency in Chemical Processing

4. How Filter Press Grilles Improve Operational Efficiency

4.1 Enhanced Filtration Rates

4.2 Reduced Downtime and Maintenance Costs

5. Applications of Filter Press Grilles in the Chemical Industry

5.1 Wastewater Treatment

5.2 Pharmaceutical Manufacturing

5.3 Food and Beverage Processing

6. Selecting the Right Filter Press Grille for Your Needs

6.1 Assessing Your Filtration Requirements

6.2 Comparing Different Types of Filter Press Grilles

7. Future Trends in Filter Press Technology

8. Frequently Asked Questions (FAQs)

Conclusion: Embracing Filter Press Grilles for Optimal Efficiency

1. Introduction to Chemical Processing and Filter Press Grilles

In the realm of chemical processing, maintaining high efficiency is paramount for operational success. One of the critical components that contribute to this efficiency is the **filter press grille**. These specialized systems aid in separating solids from liquids, ensuring that operations remain smooth and effective. In this article, we will delve into the essential role filter press grilles play in enhancing efficiency within the chemical processing sector.

2. Understanding Filter Press Grilles: Design and Functionality

2.1 What Are Filter Press Grilles?

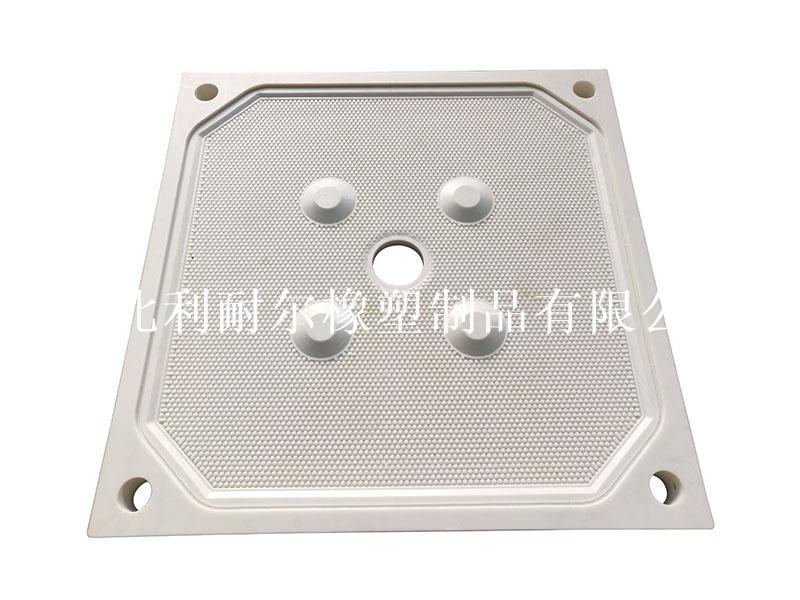

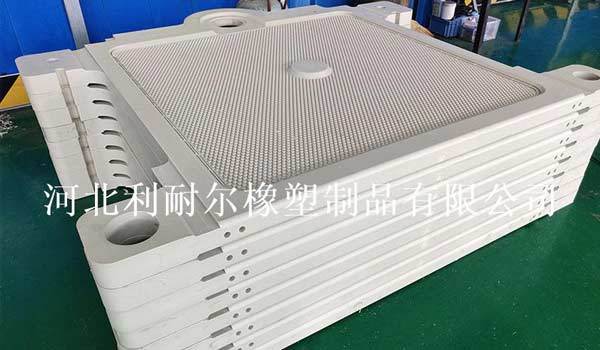

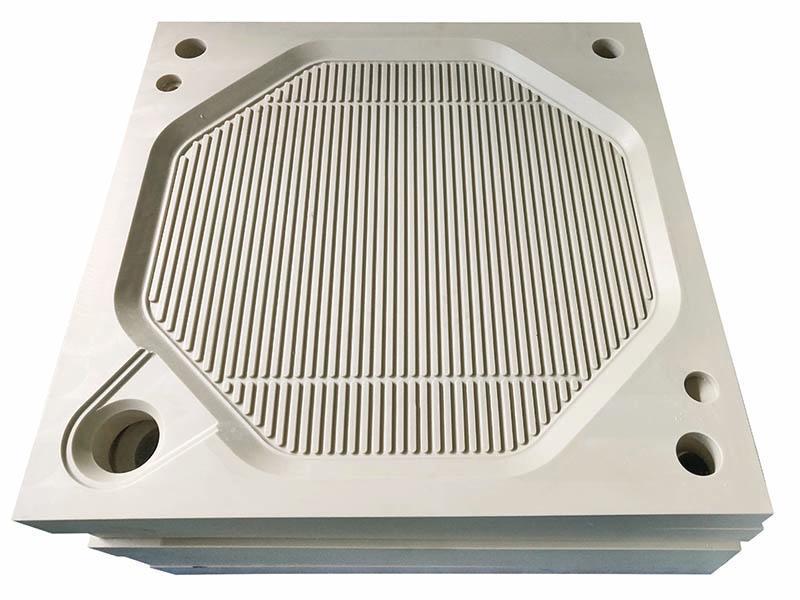

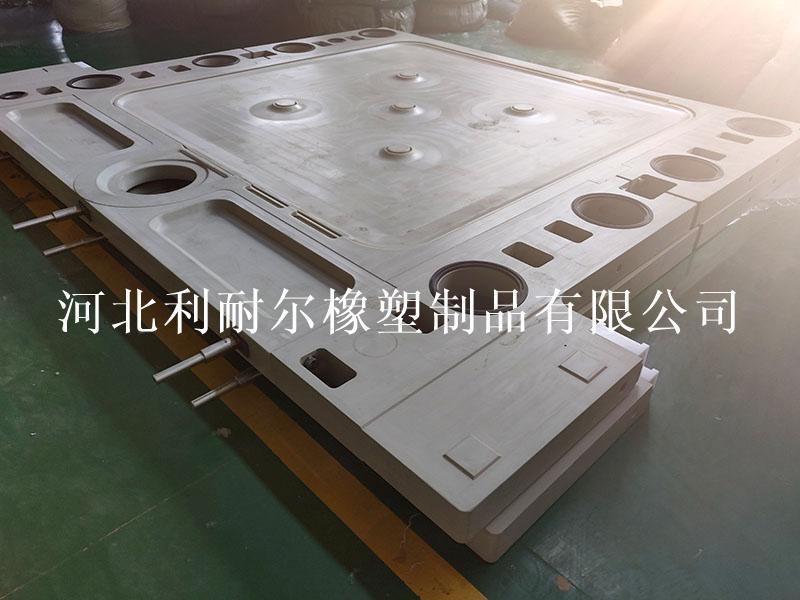

Filter press grilles are mechanical devices designed to separate solids from liquids in various industrial processes. These systems utilize the principle of pressure filtration, where a slurry is pumped into the filter press, and the liquid passes through the filter medium, leaving behind the solid particles. The end result is a cleaner liquid and a solid cake that can be further processed or disposed of.

2.2 Key Components of Filter Press Grilles

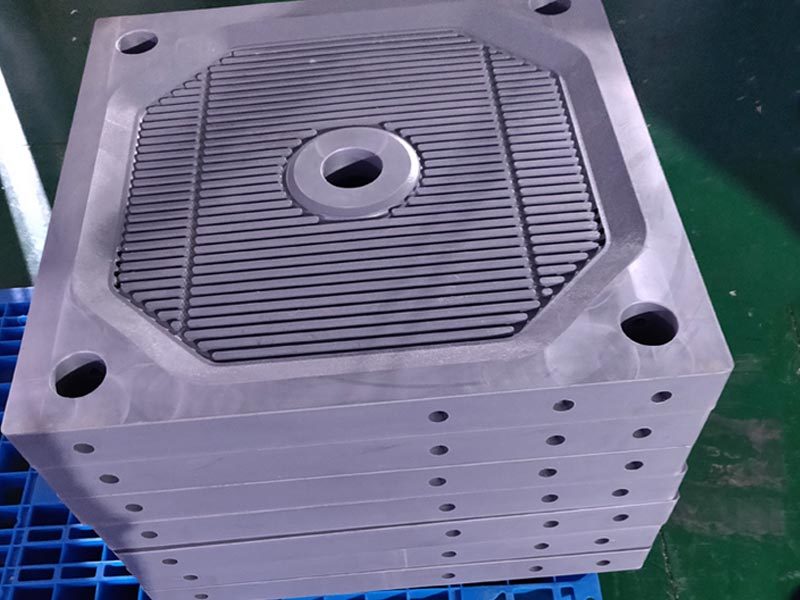

The main components of filter press grilles include the frame, filter plates, filter cloths, and hydraulic systems. The **frame** provides structural support, while **filter plates** hold the filter cloths that capture solids during the filtration process. The **hydraulic system** operates the pressing mechanism, ensuring that the plates are tightly sealed during operation to maximize filtration efficiency.

3. The Importance of Efficiency in Chemical Processing

Efficiency in chemical processing can significantly impact productivity, cost-effectiveness, and overall output quality. With rising competition and stringent environmental regulations, companies must seek innovative solutions that enhance operational efficiency while adhering to safety and compliance standards. Filter press grilles emerge as a viable solution, as they help to streamline processes, reduce waste, and improve the quality of final products.

4. How Filter Press Grilles Improve Operational Efficiency

4.1 Enhanced Filtration Rates

One of the primary benefits of using filter press grilles is their ability to achieve **enhanced filtration rates**. These systems can handle high volumes of slurry, allowing for faster processing times and increased throughput. By optimizing the filtration process, companies can meet production targets and reduce lead times.

4.2 Reduced Downtime and Maintenance Costs

Filter press grilles are designed for durability and reliability. Their robust construction minimizes the risk of breakdowns and malfunctions, leading to **reduced downtime and maintenance costs**. With fewer interruptions in operations, companies can ensure a consistent flow of production, thereby maximizing their efficiency and profitability.

5. Applications of Filter Press Grilles in the Chemical Industry

Filter press grilles find applications across various sectors of the chemical industry. Below are some specific areas where these systems are particularly valuable.

5.1 Wastewater Treatment

In wastewater treatment facilities, filter press grilles efficiently separate solids from liquid effluents. This process not only helps in achieving regulatory compliance but also allows for the recovery of valuable resources from wastewater streams.

5.2 Pharmaceutical Manufacturing

Pharmaceutical companies utilize filter press grilles to ensure the purity of their products. By removing impurities and contaminants from active pharmaceutical ingredients, these systems play a crucial role in maintaining consistent product quality and safety.

5.3 Food and Beverage Processing

In the food and beverage industry, filter press grilles are employed to clarify liquids and remove suspended solids. This contributes to improved product quality and shelf life, ensuring that consumers receive safe and high-quality products.

6. Selecting the Right Filter Press Grille for Your Needs

Choosing the appropriate filter press grille is essential for maximizing efficiency in your operations. Here’s what to consider:

6.1 Assessing Your Filtration Requirements

Before selecting a filter press grille, assess your specific filtration needs. Consider factors such as the type of slurry, volume, and desired filtration speed. This information will guide you in selecting a system that meets your operational requirements.

6.2 Comparing Different Types of Filter Press Grilles

Not all filter press grilles are created equal. Various types are available, each designed for specific applications and industries. Evaluate the features, benefits, and specifications of different models to determine which one aligns best with your processing goals.

7. Future Trends in Filter Press Technology

As technology continues to advance, filter press systems are evolving to meet the changing demands of the chemical industry. Innovations such as automation, smart technology integration, and advanced materials are enhancing the efficiency and effectiveness of filter press grilles. Companies that embrace these trends will likely gain a competitive edge in the marketplace.

8. Frequently Asked Questions (FAQs)

1. What is the primary function of a filter press grille?

The primary function of a filter press grille is to separate solids from liquids in various industrial processes, enhancing the efficiency of filtration.

2. How do filter press grilles improve efficiency?

Filter press grilles improve efficiency by increasing filtration rates, reducing downtime, and minimizing maintenance costs.

3. In which industries are filter press grilles commonly used?

Filter press grilles are commonly used in wastewater treatment, pharmaceutical manufacturing, and food and beverage processing.

4. How do I select the right filter press grille for my needs?

To select the right filter press grille, assess your filtration requirements and compare different models based on their specifications and features.

5. What are the future trends in filter press technology?

Future trends in filter press technology include automation, smart technology integration, and the use of advanced materials to enhance performance.

Conclusion: Embracing Filter Press Grilles for Optimal Efficiency

In the competitive landscape of chemical processing, maximizing efficiency is more critical than ever. **Filter press grilles** serve as a vital component in achieving this goal, offering significant benefits such as enhanced filtration rates, reduced downtime, and versatile applications across various industries. By understanding the pivotal role these systems play and selecting the right equipment for your specific needs, you can ensure operational success and maintain a competitive advantage. Embrace filter press grilles today to unlock the full potential of your chemical processing operations.

Related News