Understanding Filter Press Sealing Strips: An Essential Component in Industrial Applications

Release time:

2025-02-07

In the realm of industrial equipment, filter press sealing strips play a pivotal role in maintaining the efficiency and effectiveness of filtration processes. A filter press is a mechanical device used for separating solids from liquids in a variety of applications, ranging from wastewater treatment to mineral processing. The sealing strips are integral to the functioning of these machines, provid

In the realm of industrial equipment, filter press sealing strips play a pivotal role in maintaining the efficiency and effectiveness of filtration processes. A filter press is a mechanical device used for separating solids from liquids in a variety of applications, ranging from wastewater treatment to mineral processing. The sealing strips are integral to the functioning of these machines, providing a tight seal that prevents any leakage during operation.

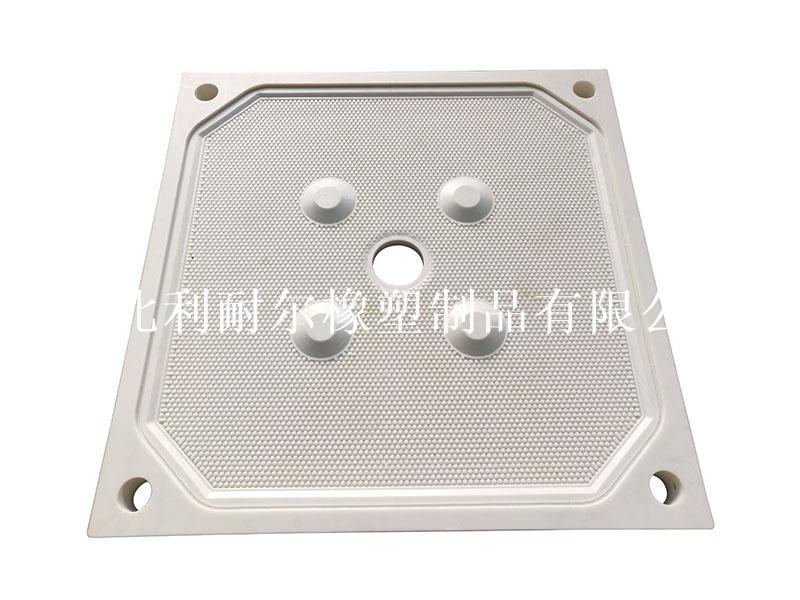

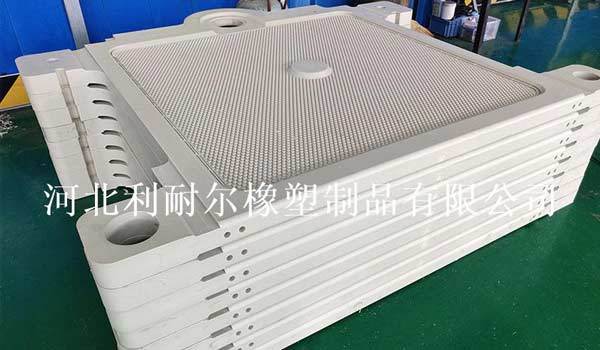

The primary function of a filter press sealing strip is to create a barrier between the filter plates, ensuring that the slurry being processed is contained within the press. This containment is crucial because any leaks can lead to material loss, contamination of the filtered liquid, and reduced overall efficiency. Therefore, having high-quality sealing strips is essential for the smooth operation of filter presses.

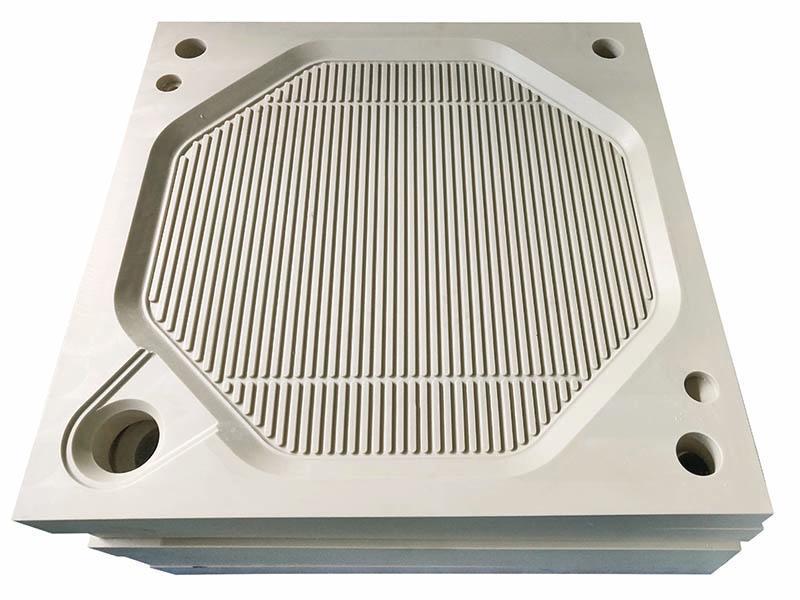

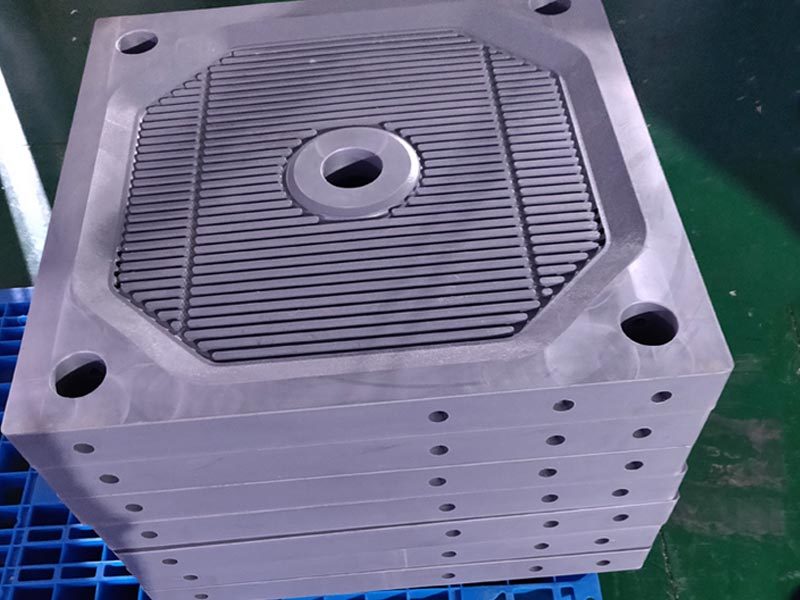

There are several materials used in the manufacture of filter press sealing strips, each chosen based on specific operational requirements. Common materials include rubber, polyurethane, and silicone, which offer different levels of resistance to chemicals, temperatures, and wear. When selecting a sealing strip, it is vital to consider the nature of the materials being filtered, as well as the environmental conditions within which the filter press operates.

Moreover, the design of the sealing strip can significantly impact its performance. Various shapes and configurations are available to accommodate different filter press designs, ensuring an optimal fit that enhances sealing capabilities. Regular inspection and maintenance of these sealing strips are also important to avoid premature wear and tear, which can compromise the efficiency of the filtration process.

In addition to preventing leaks, filter press sealing strips contribute to the longevity of the equipment. A proper seal reduces the strain on the machine components, decreasing the likelihood of mechanical failures and the associated downtime for repairs. This not only saves costs in terms of maintenance but also boosts productivity in high-demand industrial environments.

Filter press sealing strips are often overlooked, yet they are vital for ensuring the reliability and effectiveness of filtration systems. By investing in quality sealing strips and adhering to best practices for installation and maintenance, industries can significantly enhance their operational efficiency and reduce costs over time.

In conclusion, understanding the importance of filter press sealing strips is essential for anyone involved in industrial operations. These components are not just simple accessories; they are fundamental to the functionality and efficiency of filter presses, protecting valuable resources and enhancing productivity in the process.

The primary function of a filter press sealing strip is to create a barrier between the filter plates, ensuring that the slurry being processed is contained within the press. This containment is crucial because any leaks can lead to material loss, contamination of the filtered liquid, and reduced overall efficiency. Therefore, having high-quality sealing strips is essential for the smooth operation of filter presses.

There are several materials used in the manufacture of filter press sealing strips, each chosen based on specific operational requirements. Common materials include rubber, polyurethane, and silicone, which offer different levels of resistance to chemicals, temperatures, and wear. When selecting a sealing strip, it is vital to consider the nature of the materials being filtered, as well as the environmental conditions within which the filter press operates.

Moreover, the design of the sealing strip can significantly impact its performance. Various shapes and configurations are available to accommodate different filter press designs, ensuring an optimal fit that enhances sealing capabilities. Regular inspection and maintenance of these sealing strips are also important to avoid premature wear and tear, which can compromise the efficiency of the filtration process.

In addition to preventing leaks, filter press sealing strips contribute to the longevity of the equipment. A proper seal reduces the strain on the machine components, decreasing the likelihood of mechanical failures and the associated downtime for repairs. This not only saves costs in terms of maintenance but also boosts productivity in high-demand industrial environments.

Filter press sealing strips are often overlooked, yet they are vital for ensuring the reliability and effectiveness of filtration systems. By investing in quality sealing strips and adhering to best practices for installation and maintenance, industries can significantly enhance their operational efficiency and reduce costs over time.

In conclusion, understanding the importance of filter press sealing strips is essential for anyone involved in industrial operations. These components are not just simple accessories; they are fundamental to the functionality and efficiency of filter presses, protecting valuable resources and enhancing productivity in the process.

Related News