Exploring the Environmental Impact of 1200 Filter Plates in Industry: A Comprehensive Analysis

Release time:

2025-02-03

Exploring the Environmental Impact of 1200 Filter Plates in Industry Table of Contents Introduction: The Role of Filter Plates in Industrial Applications What Are 1200 Filter Plates? Applications of 1200 Filter Plates in Various Industries Environmental Benefits of Using 1200 Filter Plates Potential Environmental Impact of 1200 Filter Plates Sustainability Initiatives in F

Exploring the Environmental Impact of 1200 Filter Plates in Industry

Table of Contents

- Introduction: The Role of Filter Plates in Industrial Applications

- What Are 1200 Filter Plates?

- Applications of 1200 Filter Plates in Various Industries

- Environmental Benefits of Using 1200 Filter Plates

- Potential Environmental Impact of 1200 Filter Plates

- Sustainability Initiatives in Filter Plate Manufacturing

- Best Practices for Environmental Safety with Filter Plates

- Conclusion: Balancing Industrial Needs with Environmental Responsibility

- FAQs

Introduction: The Role of Filter Plates in Industrial Applications

In today’s industrial landscape, the quest for efficient and environmentally friendly processes is more critical than ever. **1200 filter plates** serve as a cornerstone in numerous industrial applications. These plates play pivotal roles in separating solids from liquids, contributing to a variety of processes, including wastewater treatment, food production, and chemical processing. Understanding their environmental impact is essential for industries striving to adopt sustainable practices while maintaining operational efficiency.

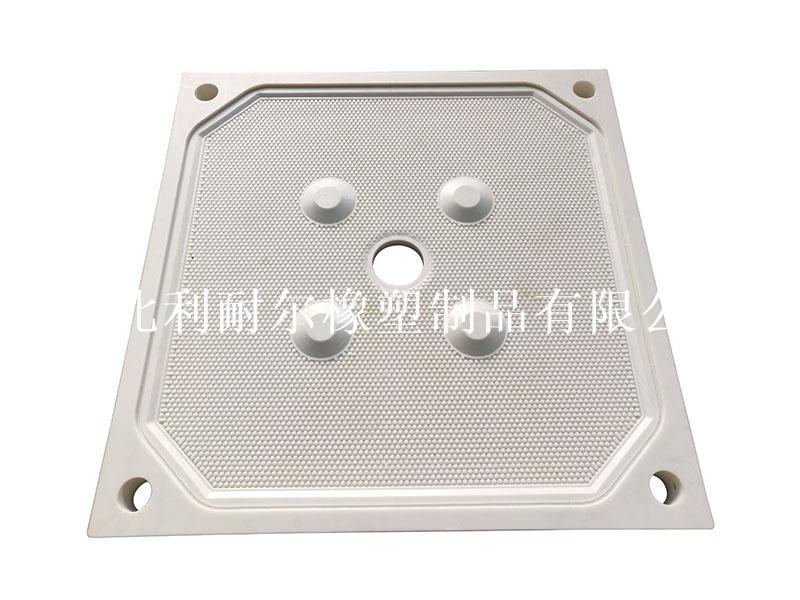

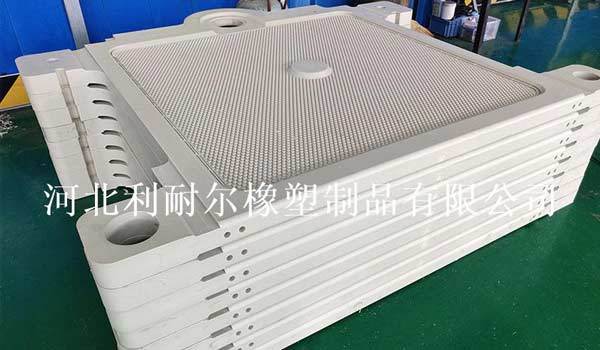

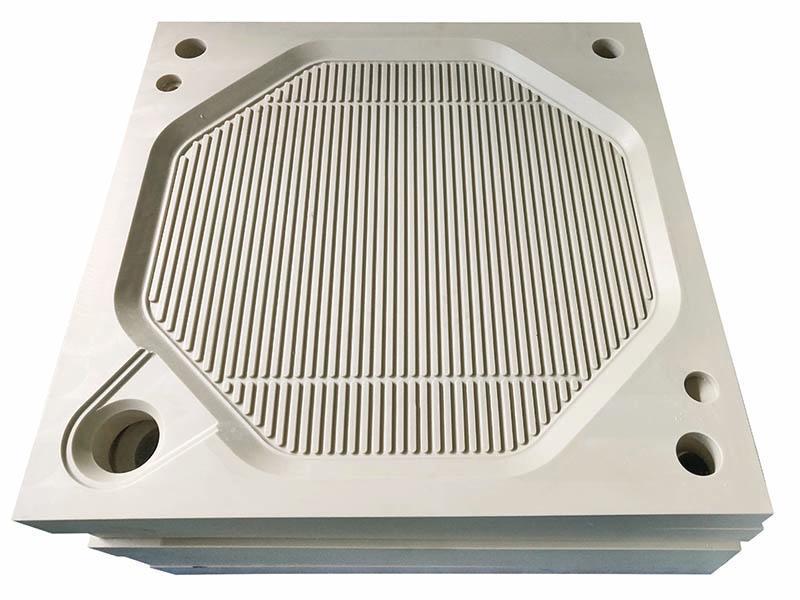

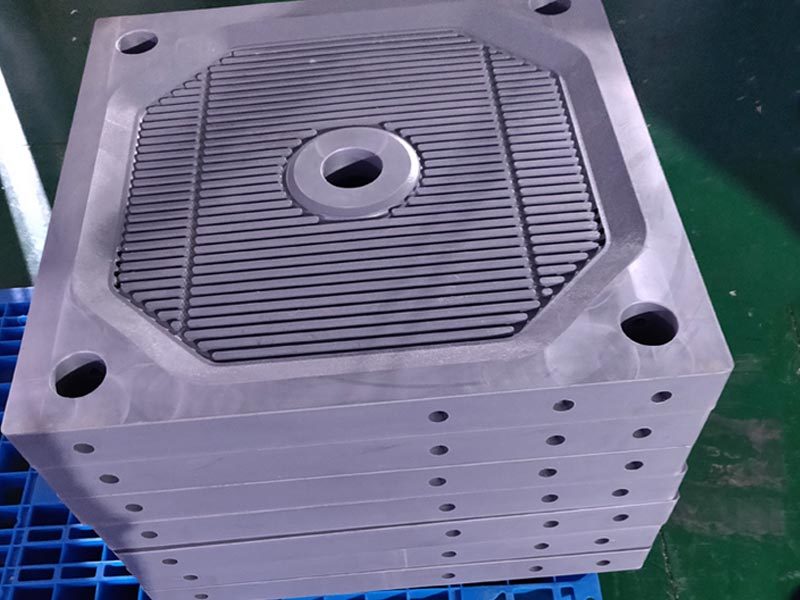

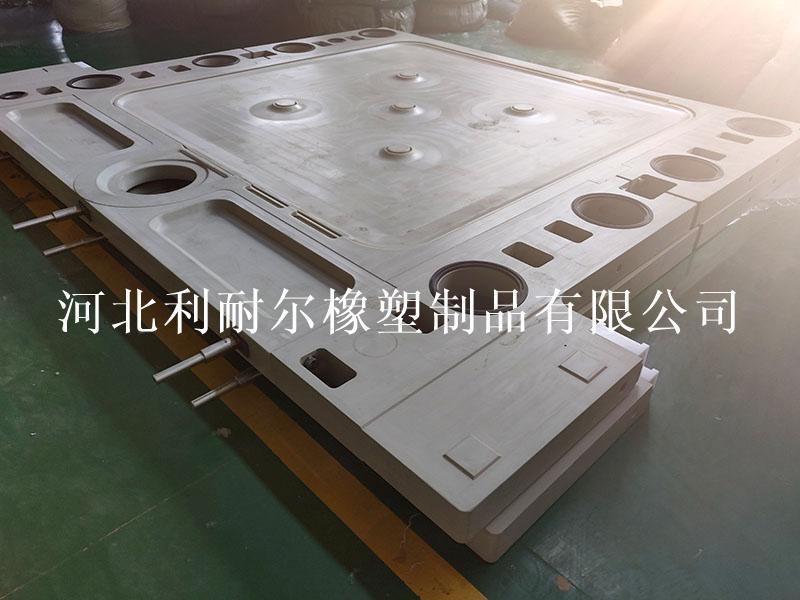

What Are 1200 Filter Plates?

**1200 filter plates** are specialized filtration devices made from durable materials such as polypropylene or polyvinyl chloride (PVC). They are designed to separate solids from liquids through a combination of pressure and gravity-driven filtration. Typically rectangular in shape, these plates feature a series of chambers that allow for the efficient collection of filtered solids while permitting clean liquid to flow through. Their versatility makes them suitable for a wide range of applications across various sectors, including chemical manufacturing, mining, and pharmaceuticals.

Applications of 1200 Filter Plates in Various Industries

The use of 1200 filter plates spans numerous industries, showcasing their adaptability and efficiency:

1. Wastewater Treatment

In wastewater treatment plants, **1200 filter plates** are indispensable for removing contaminants from industrial effluents. They help in achieving regulatory compliance while minimizing environmental impact.

2. Food and Beverage Processing

In the food industry, filter plates are utilized to clarify beverages and extract juices, ensuring product purity and safety. Using these plates enhances product quality and extends shelf life.

3. Chemical Processing

Chemical manufacturers rely on 1200 filter plates to separate valuable products from by-products and waste materials, optimizing resource utilization and reducing disposal costs.

4. Mining and Mineral Processing

In the mining sector, filter plates efficiently separate minerals from slurries, facilitating the recovery of valuable resources and minimizing environmental disruption.

Environmental Benefits of Using 1200 Filter Plates

The adoption of **1200 filter plates** contributes significantly to environmental sustainability. Here are some key benefits:

1. Efficient Resource Management

By maximizing the recovery of valuable materials, filter plates help industries shift towards a circular economy model, reducing waste generation and promoting recycling.

2. Reduced Water Pollution

Effective filtration reduces the amount of pollutants released into water bodies, safeguarding aquatic ecosystems and improving water quality for communities.

3. Lower Energy Consumption

Advanced filtration technologies, including 1200 filter plates, often require less energy than traditional methods, leading to decreased carbon footprints for companies.

4. Enhanced Compliance with Environmental Regulations

Utilizing these filter plates helps industries comply with stringent environmental regulations, thereby avoiding fines and enhancing their reputation.

Potential Environmental Impact of 1200 Filter Plates

Despite their benefits, the environmental impact of 1200 filter plates cannot be overlooked. Some potential concerns include:

1. Manufacturing Footprint

The production of filter plates involves the extraction and processing of raw materials, which can lead to environmental degradation if not managed responsibly.

2. Disposal Challenges

End-of-life filter plates may pose disposal challenges, particularly if they are made from non-biodegradable materials. Adopting sustainable disposal methods is crucial.

3. Chemical Leaching

In certain conditions, components of filter plates may leach into the environment, potentially contaminating soil and water systems.

4. Resource Intensity

While filter plates can enhance efficiency, their resource-intensive manufacturing process may offset some environmental benefits if not managed properly.

Sustainability Initiatives in Filter Plate Manufacturing

To mitigate the environmental impacts associated with 1200 filter plates, several manufacturers are adopting sustainable practices:

1. Eco-friendly Materials

Some companies are developing filter plates using recycled and biodegradable materials to reduce environmental impact.

2. Energy-efficient Production Processes

Implementing energy-efficient manufacturing processes can significantly lower the carbon footprint associated with filter plate production.

3. Life Cycle Assessments

Conducting life cycle assessments (LCAs) allows manufacturers to identify areas for improvement and implement strategies for reducing resource use and emissions.

4. End-of-life Management Programs

Establishing end-of-life management programs encourages recycling and safe disposal of filter plates, safeguarding the environment.

Best Practices for Environmental Safety with Filter Plates

Industries utilizing 1200 filter plates can implement several best practices to ensure environmental safety:

1. Regular Maintenance and Monitoring

Conducting routine maintenance and monitoring of filter plates can prevent leaks and ensure optimal performance, reducing the risk of environmental contamination.

2. Employee Training

Training employees on proper handling and disposal practices for filter plates fosters a culture of environmental responsibility within organizations.

3. Investment in Advanced Filtration Technologies

Investing in cutting-edge filtration technologies can enhance efficiency and minimize environmental impact, benefiting both the industry and the planet.

4. Collaboration with Environmental Agencies

Partnering with environmental agencies can provide valuable resources and guidelines for best practices in waste management and sustainability.

Conclusion: Balancing Industrial Needs with Environmental Responsibility

In conclusion, **1200 filter plates** serve as vital tools in various industrial processes, significantly contributing to efficiency and sustainability. However, recognizing their environmental impacts is crucial for industries aiming to balance operational needs with ecological responsibility. By adopting sustainable manufacturing practices, investing in advanced technologies, and implementing best practices, we can harness the benefits of filter plates while mitigating potential environmental risks. Ultimately, fostering a culture of environmental stewardship will lead to a more sustainable industrial future.

FAQs

1. What industries use 1200 filter plates?

1200 filter plates are widely used in industries such as wastewater treatment, food and beverage processing, chemical manufacturing, and mining.

2. What materials are 1200 filter plates made from?

They are typically made from durable materials like polypropylene or PVC, which offer resistance to chemicals and extreme conditions.

3. How do filter plates help reduce environmental impact?

Filter plates enhance resource recovery, reduce water pollution, lower energy consumption, and help companies comply with environmental regulations.

4. What are the disposal challenges associated with filter plates?

Disposal challenges include potential contamination from non-biodegradable materials and the need for proper recycling or disposal methods.

5. How can industries ensure the environmental safety of filter plates?

Industries can ensure environmental safety through regular maintenance, employee training, investment in advanced technologies, and collaboration with environmental agencies.

Related News