The Essential Role of 1100 Filter Plates in the Chemical and Plastics Industry

Release time:

2025-01-30

In the chemical and plastics industry, the importance of filtration cannot be overstated. One critical component in many filtration systems is the 1100 filter plate. These filter plates serve a fundamental role in separating solid materials from liquids, ensuring that the final product meets the required quality standards. The 1100 filter plate is typically made from high-quality materials, desig

In the chemical and plastics industry, the importance of filtration cannot be overstated. One critical component in many filtration systems is the 1100 filter plate. These filter plates serve a fundamental role in separating solid materials from liquids, ensuring that the final product meets the required quality standards.

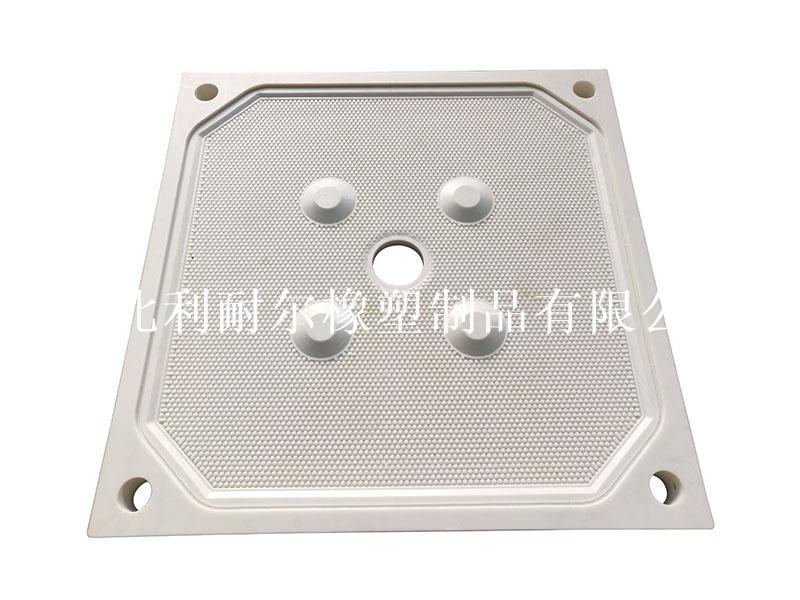

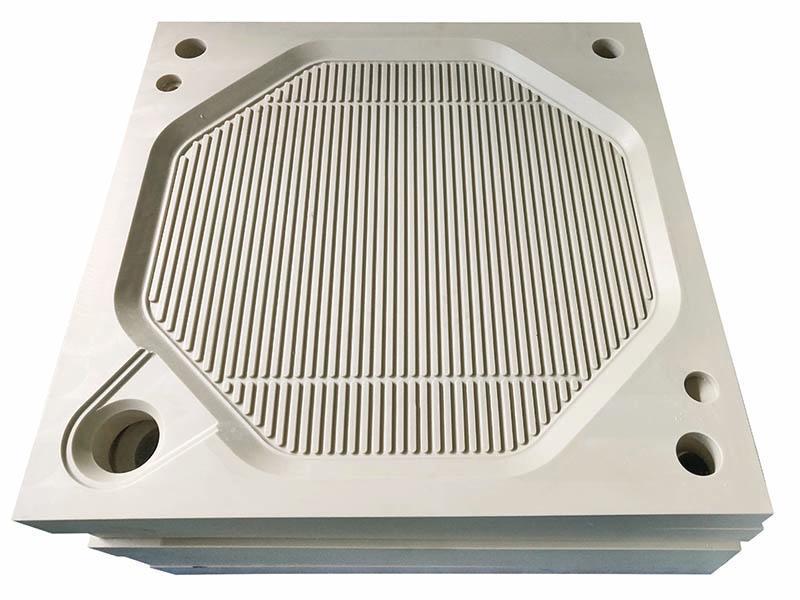

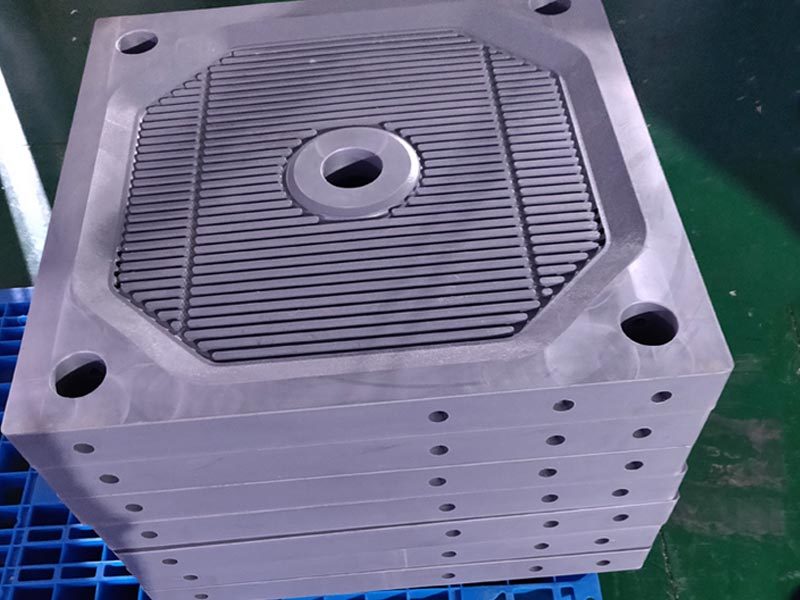

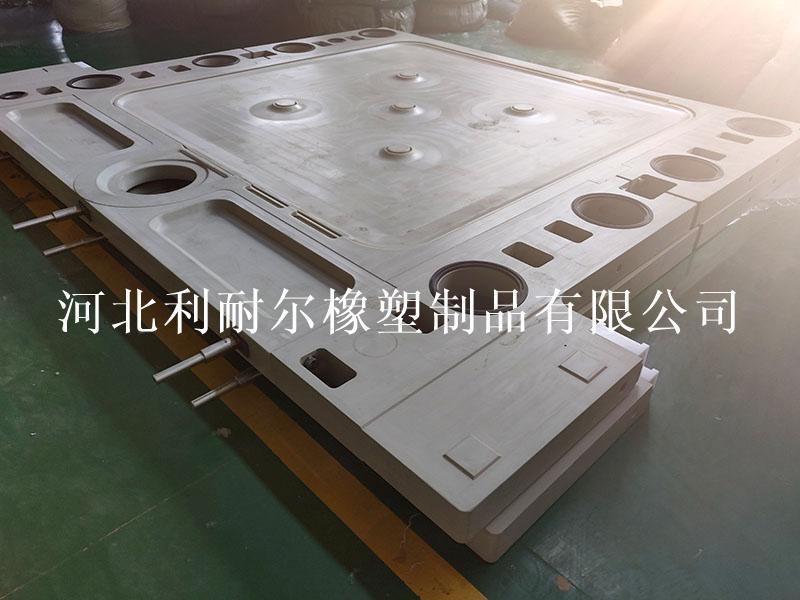

The 1100 filter plate is typically made from high-quality materials, designed to withstand the rigorous conditions often found in chemical processing applications. Its robust construction allows it to handle various chemicals, making it a versatile choice for different types of operations. The design of the filter plate maximizes surface area, improving filtration efficiency while minimizing clogging. This characteristic is particularly valuable in applications where high volumes of particulate matter are present.

One of the primary benefits of using 1100 filter plates is their ability to enhance the purity of the end product. In the plastics industry, impurities can lead to defects and inconsistencies in the final product. By employing 1100 filter plates, manufacturers can reduce contaminants in their processes, thus improving the overall quality of the plastics produced. This quality assurance is crucial, as customers demand high performance and reliability from plastic products.

Moreover, the use of 1100 filter plates can lead to significant cost savings. By improving filtration efficiency and reducing downtime caused by clogging or maintenance, businesses can optimize their operations. Efficient filtration systems can also reduce the need for additional processing steps, further streamlining production. This efficiency translates into lower operational costs and increased profitability, making it a smart investment for companies in the chemical and plastics industry.

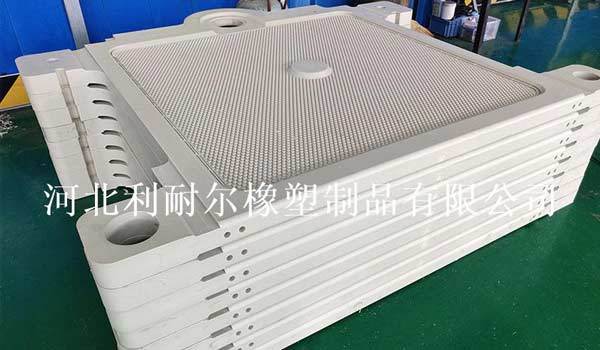

Another notable aspect of 1100 filter plates is their adaptability. They can be used in various configurations and can be customized to meet specific operational requirements. This flexibility allows companies to integrate these filter plates into existing systems without major modifications, ensuring a smooth transition and minimal disruption to operations.

In conclusion, 1100 filter plates are an indispensable component in the chemical and plastics industry. Their ability to enhance product quality, improve operational efficiency, and provide adaptability makes them an essential consideration for manufacturers. As the industry continues to evolve, the role of effective filtration systems, including 1100 filter plates, will remain crucial in meeting the growing demands for high-quality plastic products. By investing in such filtration solutions, companies can position themselves for success in a competitive market.

The 1100 filter plate is typically made from high-quality materials, designed to withstand the rigorous conditions often found in chemical processing applications. Its robust construction allows it to handle various chemicals, making it a versatile choice for different types of operations. The design of the filter plate maximizes surface area, improving filtration efficiency while minimizing clogging. This characteristic is particularly valuable in applications where high volumes of particulate matter are present.

One of the primary benefits of using 1100 filter plates is their ability to enhance the purity of the end product. In the plastics industry, impurities can lead to defects and inconsistencies in the final product. By employing 1100 filter plates, manufacturers can reduce contaminants in their processes, thus improving the overall quality of the plastics produced. This quality assurance is crucial, as customers demand high performance and reliability from plastic products.

Moreover, the use of 1100 filter plates can lead to significant cost savings. By improving filtration efficiency and reducing downtime caused by clogging or maintenance, businesses can optimize their operations. Efficient filtration systems can also reduce the need for additional processing steps, further streamlining production. This efficiency translates into lower operational costs and increased profitability, making it a smart investment for companies in the chemical and plastics industry.

Another notable aspect of 1100 filter plates is their adaptability. They can be used in various configurations and can be customized to meet specific operational requirements. This flexibility allows companies to integrate these filter plates into existing systems without major modifications, ensuring a smooth transition and minimal disruption to operations.

In conclusion, 1100 filter plates are an indispensable component in the chemical and plastics industry. Their ability to enhance product quality, improve operational efficiency, and provide adaptability makes them an essential consideration for manufacturers. As the industry continues to evolve, the role of effective filtration systems, including 1100 filter plates, will remain crucial in meeting the growing demands for high-quality plastic products. By investing in such filtration solutions, companies can position themselves for success in a competitive market.

Related News