Exploring the Benefits of 1000 Filter Plates in Industrial Applications

Release time:

2025-01-26

Exploring the Benefits of 1000 Filter Plates in Industrial Applications Table of Contents Introduction to 1000 Filter Plates Understanding Filter Plates: What They Are and How They Work The Multifaceted Benefits of Using 1000 Filter Plates Applications of 1000 Filter Plates in Various Industries Enhancing Efficiency and Performance with 1000 Filter Plates Sustainability and Environmen

Exploring the Benefits of 1000 Filter Plates in Industrial Applications

Table of Contents

- Introduction to 1000 Filter Plates

- Understanding Filter Plates: What They Are and How They Work

- The Multifaceted Benefits of Using 1000 Filter Plates

- Applications of 1000 Filter Plates in Various Industries

- Enhancing Efficiency and Performance with 1000 Filter Plates

- Sustainability and Environmental Impact of 1000 Filter Plates

- Maintenance and Care for Optimal Performance

- Frequently Asked Questions (FAQs)

- Conclusion: Why 1000 Filter Plates Are Essential for Modern Industries

Introduction to 1000 Filter Plates

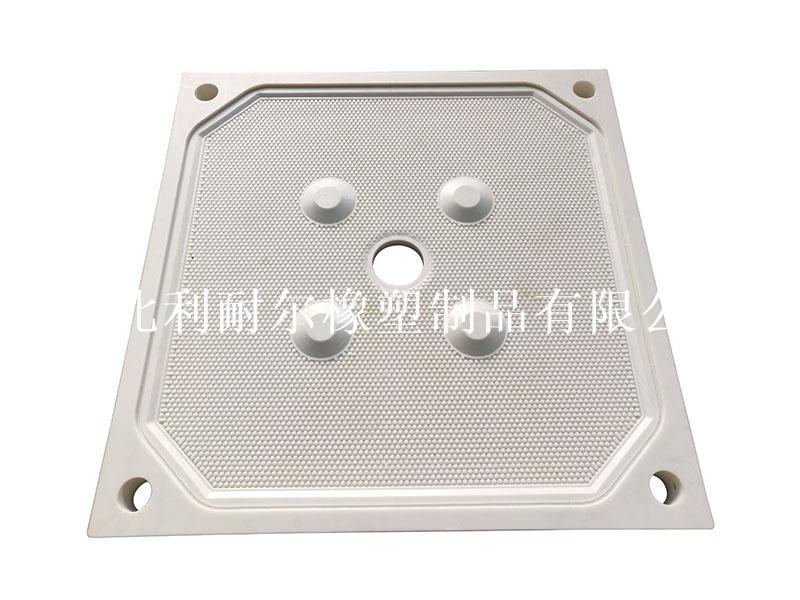

In today’s industrial landscape, efficiency and precision are paramount. **1000 filter plates** have emerged as a game-changing solution, streamlining processes and enhancing production quality. Designed to meet the rigorous demands of various industries, these filter plates facilitate effective separation and purification of liquids and slurries. By exploring their benefits, we can better appreciate their role in modern manufacturing environments.

Understanding Filter Plates: What They Are and How They Work

Filter plates are essential components employed in filtration systems, primarily used in industries such as food and beverage, pharmaceuticals, and wastewater treatment. They are designed to separate solids from liquids, allowing for efficient processing and enhancing product purity.

**How Filter Plates Function**

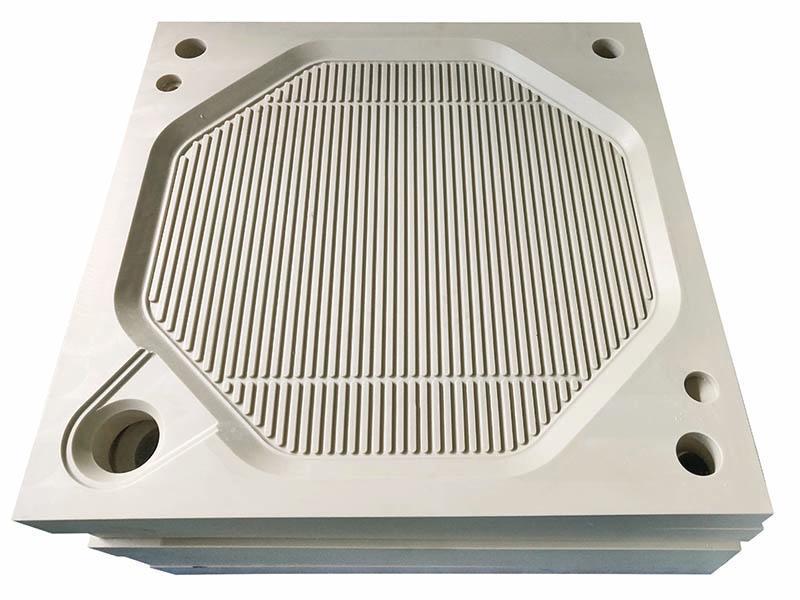

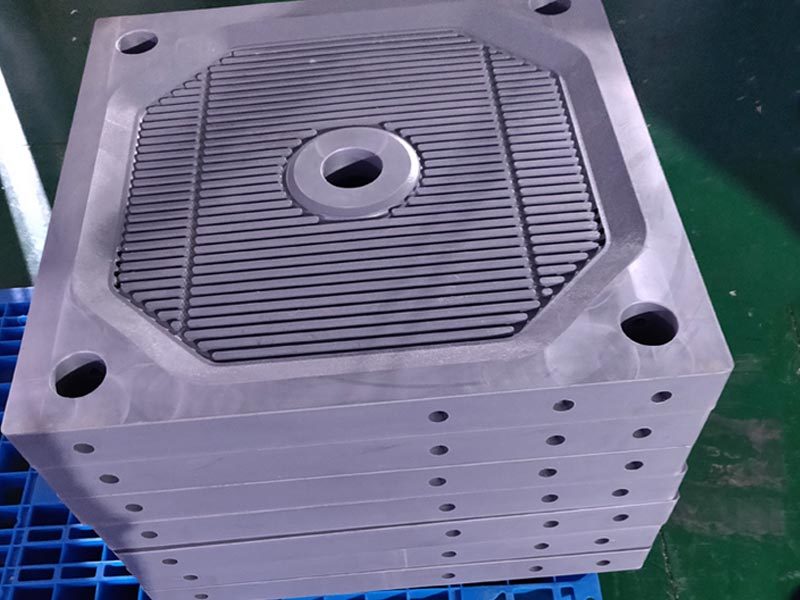

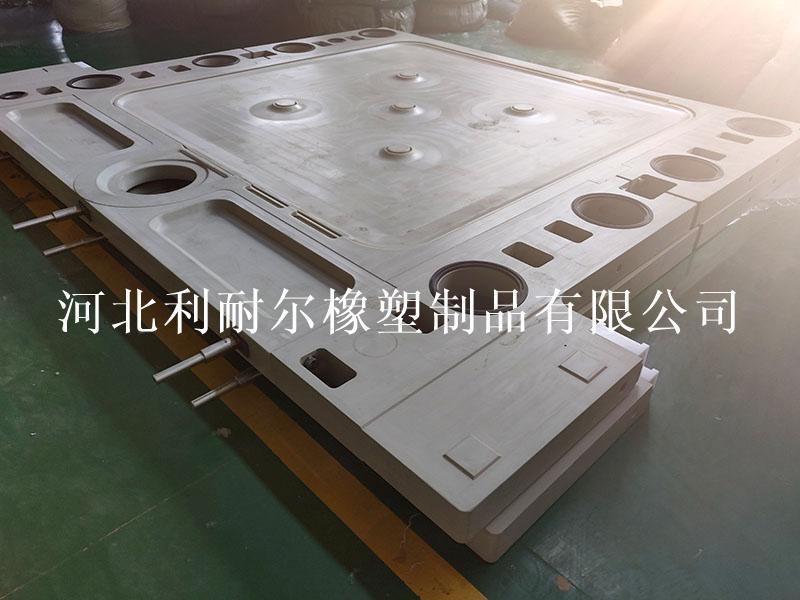

Typically, filter plates consist of a durable material, often polypropylene or stainless steel, configured in a way that allows liquids to pass through while trapping solid particles. The **1000 filter plates** specifically offer a unique design that maximizes surface area, enhancing the filtration process. When a slurry is introduced, the liquid moves through the filter medium, while solids accumulate on the surface, resulting in a clean effluent.

The Multifaceted Benefits of Using 1000 Filter Plates

The advantages of utilizing **1000 filter plates** are numerous and significant:

1. Enhanced Filtration Efficiency

The increased surface area of 1000 filter plates allows for greater contact with the slurry, leading to **optimized filtration efficiency**. This means more solids are captured, resulting in cleaner output.

2. Cost-Effectiveness

Investing in high-quality filter plates can significantly reduce operational costs. The durability and longevity of **1000 filter plates** minimize the need for frequent replacements, thus saving money in the long run.

3. Versatility Across Applications

These filter plates are adaptable to various industrial applications, including liquid clarification, sludge dewatering, and even in complex chemical processes. Their versatility makes them a valuable asset in any industrial setting.

4. Improved Product Quality

By ensuring effective separation of solids from liquids, 1000 filter plates play a vital role in maintaining product integrity. This is especially crucial in sectors like pharmaceuticals and food processing where purity is non-negotiable.

5. Sustainability Benefits

Utilizing **1000 filter plates** can lead to reduced waste generation and enhanced recycling of materials. Their efficiency in separating solids can contribute to a more sustainable manufacturing process.

Applications of 1000 Filter Plates in Various Industries

The adaptability of **1000 filter plates** extends across multiple industries:

1. Food and Beverage Industry

In the food and beverage sector, these filter plates are vital for clarifying juices, wines, and other liquids. They ensure that the final products are free from unwanted particulates, thus enhancing flavor and safety.

2. Pharmaceutical Manufacturing

In pharmaceuticals, the need for sterility and precision is paramount. **1000 filter plates** are employed in processes like bulk drug production and sterile filter applications to ensure product safety and compliance with regulatory standards.

3. Wastewater Treatment

In environmental applications, these filter plates assist in treating wastewater by effectively separating solids from liquids, ensuring that the treated water meets environmental regulations before being released back into nature.

4. Chemical Processing

Chemicals often require precise filtration to ensure product quality. **1000 filter plates** help in removing contaminants and ensuring the purity of chemical products.

Enhancing Efficiency and Performance with 1000 Filter Plates

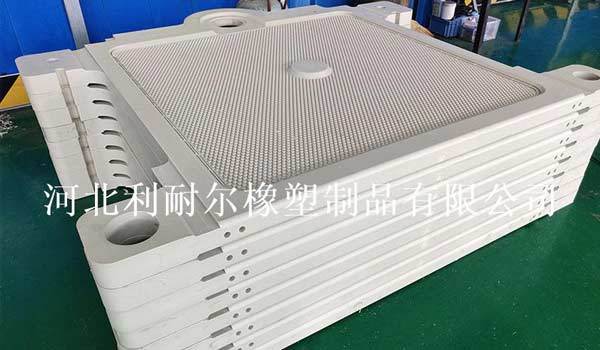

To maximize the benefits of **1000 filter plates**, industries must focus on optimizing their performance. This involves not only selecting the appropriate filter design but also considering factors such as flow rates, pressure differentials, and operational temperature.

1. Flow Rate Optimization

Understanding the flow characteristics of the materials being filtered can lead to better decision-making regarding the type and configuration of filter plates used. Higher flow rates can be achieved by selecting the right size and design.

2. Regular Monitoring and Maintenance

Routine checks and maintenance are crucial to ensure the longevity and efficiency of filter plates. Regular cleaning and inspection can prevent clogging and maintain optimal performance.

3. Training and Best Practices

Training personnel on the correct usage and maintenance of filter plates contributes to improved efficiency. Implementing best practices can significantly enhance the overall filtration process.

Sustainability and Environmental Impact of 1000 Filter Plates

The **environmental benefits** of using 1000 filter plates extend beyond waste reduction. By improving filtration processes, industries can minimize their carbon footprint and adhere to sustainability goals.

1. Reduction of Waste

Effective filtration not only improves product quality but also significantly reduces waste generation. Cleaner processes lead to less material being discarded.

2. Resource Recovery

In many cases, the solids captured during filtration can be recovered and repurposed, contributing to a circular economy. This not only conserves resources but can also create additional revenue streams.

Maintenance and Care for Optimal Performance

To fully leverage the benefits of **1000 filter plates**, proper maintenance is essential:

1. Cleaning Protocols

Establishing effective cleaning protocols ensures that filter plates remain free from contaminants and function optimally. Regular cleaning schedules should be adhered to, especially in high-use environments.

2. Inspection and Replacement

Regular inspections help identify wear and tear, prompting timely replacements. This minimizes downtime and maintains production efficiency.

Frequently Asked Questions (FAQs)

1. What materials are 1000 filter plates made from?

Typically, 1000 filter plates are constructed from durable materials such as polypropylene, stainless steel, or other robust composites designed to withstand various industrial environments.

2. How often should filter plates be cleaned?

Cleaning frequency depends on the application and material being filtered. Regular inspections can help determine optimal cleaning schedules, typically ranging from daily to weekly.

3. Can 1000 filter plates be used in high-temperature applications?

Yes, many 1000 filter plates are designed to withstand elevated temperatures. It is essential to check the specifications for the specific model to ensure suitability.

4. Are 1000 filter plates compatible with all filtration systems?

While 1000 filter plates are versatile, compatibility depends on the filtration system's design. Always consult with the manufacturer to ensure proper fit and performance.

5. What is the expected lifespan of 1000 filter plates?

The lifespan of filter plates varies based on usage and maintenance. With proper care, they can last several years, offering significant cost savings over time.

Conclusion: Why 1000 Filter Plates Are Essential for Modern Industries

In conclusion, **1000 filter plates** represent a crucial advancement in industrial filtration technology, offering numerous benefits that enhance efficiency, reduce costs, and promote sustainability. Their diverse applications across various industries demonstrate their versatility and importance in meeting modern manufacturing challenges. By incorporating 1000 filter plates into industrial processes, businesses can achieve greater operational efficiency, product quality, and environmental responsibility, paving the way for a more sustainable future.

Related News