Understanding the Role of 400 Filter Plates in Industrial Filtration

Release time:

2025-01-14

In the industrial sector, filtration plays a crucial role in maintaining the quality and safety of various processes. One important component in this realm is the 400 filter plate, which serves as a vital element in numerous filtration systems. These plates are designed to separate solids from liquids or gases, ensuring that the final output meets the necessary purity standards. The 400 filter pla

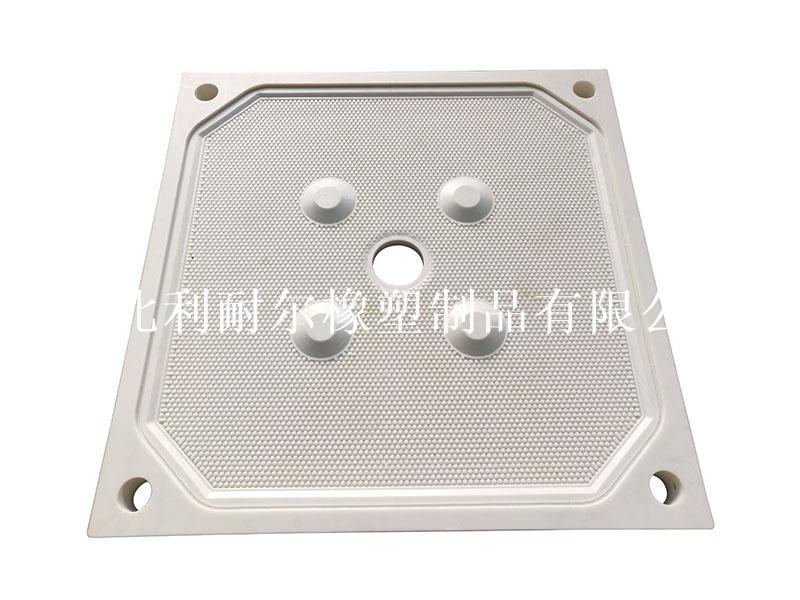

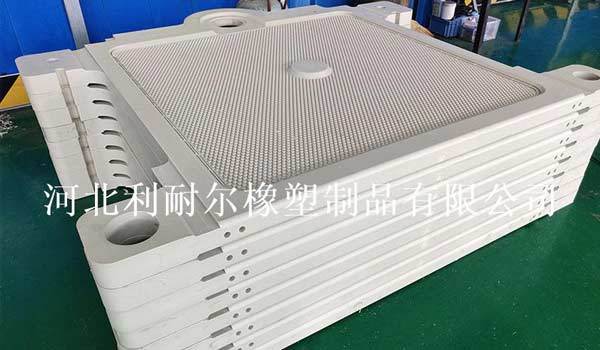

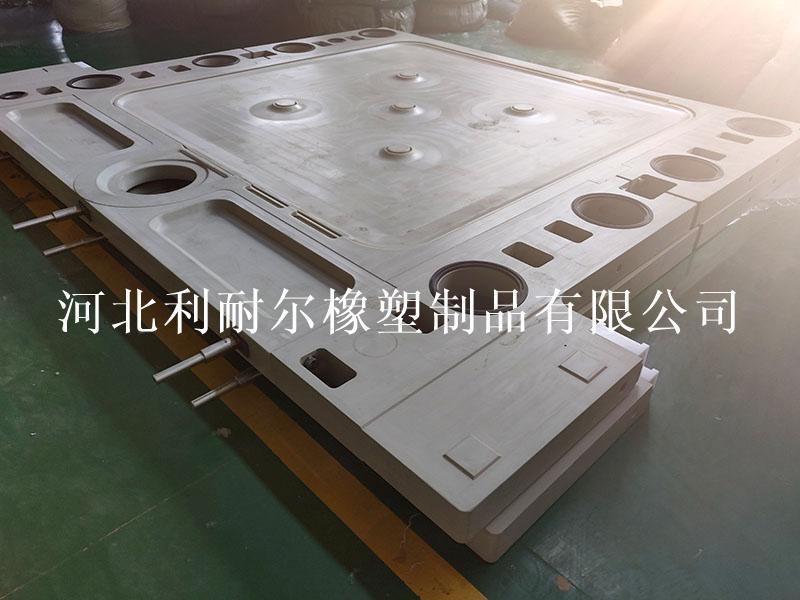

In the industrial sector, filtration plays a crucial role in maintaining the quality and safety of various processes. One important component in this realm is the 400 filter plate, which serves as a vital element in numerous filtration systems. These plates are designed to separate solids from liquids or gases, ensuring that the final output meets the necessary purity standards.

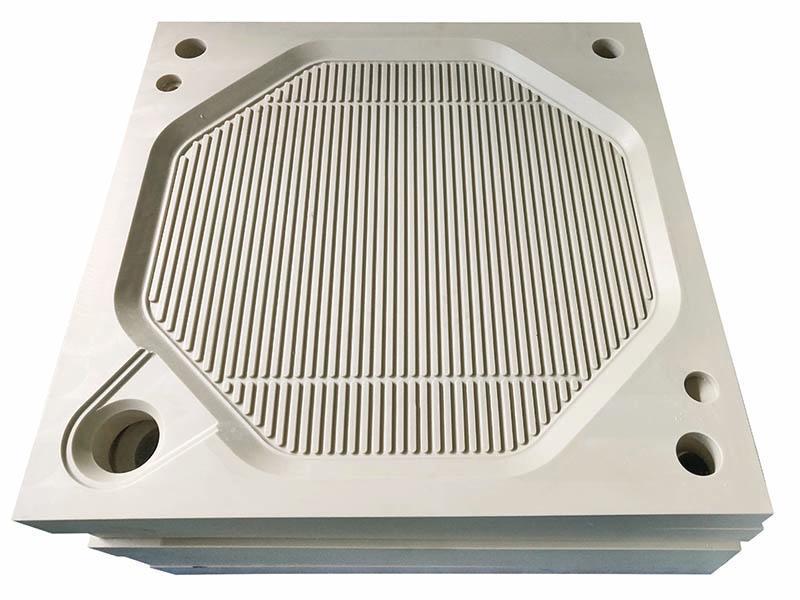

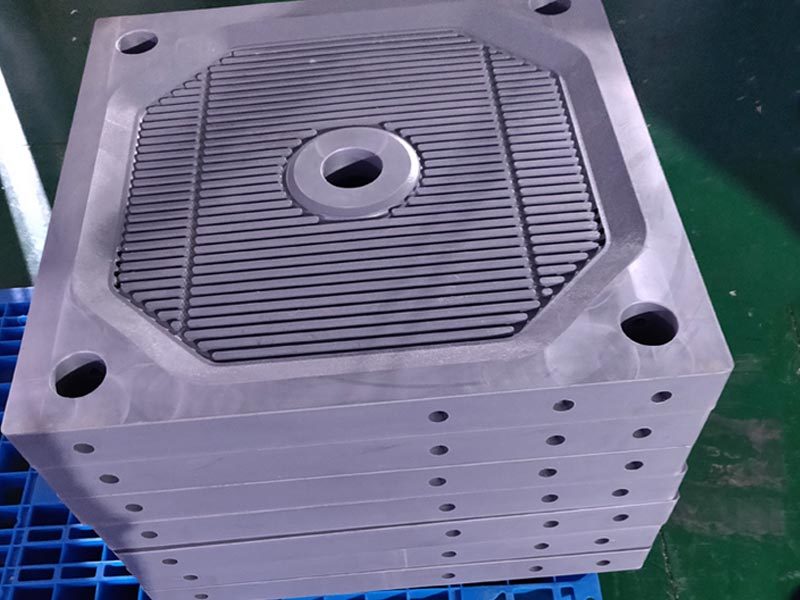

The 400 filter plate typically features a specific thickness and filtration surface area that can cater to a variety of applications. These plates are engineered to provide optimal flow rates while effectively capturing particulate matter. Their design allows for high levels of filtration efficiency, making them suitable for industries such as pharmaceuticals, food and beverage, wastewater treatment, and chemical processing.

In addition to their effectiveness, 400 filter plates are also known for their durability and reliability. Constructed from materials that can withstand harsh industrial environments, these plates demonstrate excellent resistance to corrosion, abrasion, and temperature fluctuations. This resilience ensures that the plates maintain their performance over extended periods, reducing the need for frequent replacements and minimizing downtime in operations.

One of the key advantages of using 400 filter plates is their versatility. They can be customized to meet specific filtration requirements, such as varying pore sizes or materials tailored to particular applications. This adaptability allows industries to optimize their processes by selecting the most suitable filter plate for their unique needs, thereby enhancing operational efficiency.

Furthermore, the maintenance and cleaning of 400 filter plates is relatively straightforward. Regular maintenance is essential to ensure that the filtration system operates at peak performance. By implementing proper cleaning protocols, businesses can extend the life of their filter plates and maintain the desired filtration quality. This not only leads to cost savings but also contributes to sustainable practices by minimizing waste and energy consumption.

In conclusion, the 400 filter plate plays a pivotal role in industrial filtration systems. Its combination of efficiency, durability, and adaptability makes it an indispensable tool for a wide range of industries. By understanding the characteristics and advantages of these filter plates, businesses can make informed decisions that enhance their operational capabilities and ensure compliance with industry standards. As industries continue to evolve, the relevance of quality filtration systems, including 400 filter plates, will undoubtedly remain a focal point in achieving operational excellence.

The 400 filter plate typically features a specific thickness and filtration surface area that can cater to a variety of applications. These plates are engineered to provide optimal flow rates while effectively capturing particulate matter. Their design allows for high levels of filtration efficiency, making them suitable for industries such as pharmaceuticals, food and beverage, wastewater treatment, and chemical processing.

In addition to their effectiveness, 400 filter plates are also known for their durability and reliability. Constructed from materials that can withstand harsh industrial environments, these plates demonstrate excellent resistance to corrosion, abrasion, and temperature fluctuations. This resilience ensures that the plates maintain their performance over extended periods, reducing the need for frequent replacements and minimizing downtime in operations.

One of the key advantages of using 400 filter plates is their versatility. They can be customized to meet specific filtration requirements, such as varying pore sizes or materials tailored to particular applications. This adaptability allows industries to optimize their processes by selecting the most suitable filter plate for their unique needs, thereby enhancing operational efficiency.

Furthermore, the maintenance and cleaning of 400 filter plates is relatively straightforward. Regular maintenance is essential to ensure that the filtration system operates at peak performance. By implementing proper cleaning protocols, businesses can extend the life of their filter plates and maintain the desired filtration quality. This not only leads to cost savings but also contributes to sustainable practices by minimizing waste and energy consumption.

In conclusion, the 400 filter plate plays a pivotal role in industrial filtration systems. Its combination of efficiency, durability, and adaptability makes it an indispensable tool for a wide range of industries. By understanding the characteristics and advantages of these filter plates, businesses can make informed decisions that enhance their operational capabilities and ensure compliance with industry standards. As industries continue to evolve, the relevance of quality filtration systems, including 400 filter plates, will undoubtedly remain a focal point in achieving operational excellence.

Related News