Release time:

2025-01-06

In the realm of industrial filtration systems, the 800 ✘ 800 filter plate is a fundamental component designed to enhance the efficiency of purification processes. These filter plates are specifically engineered to address a wide range of filtration requirements across different industries, including food and beverage, pharmaceuticals, chemicals, and more. The dimensions of 800 ✘ 800 indicate a squ

In the realm of industrial filtration systems, the 800 ✘ 800 filter plate is a fundamental component designed to enhance the efficiency of purification processes. These filter plates are specifically engineered to address a wide range of filtration requirements across different industries, including food and beverage, pharmaceuticals, chemicals, and more.

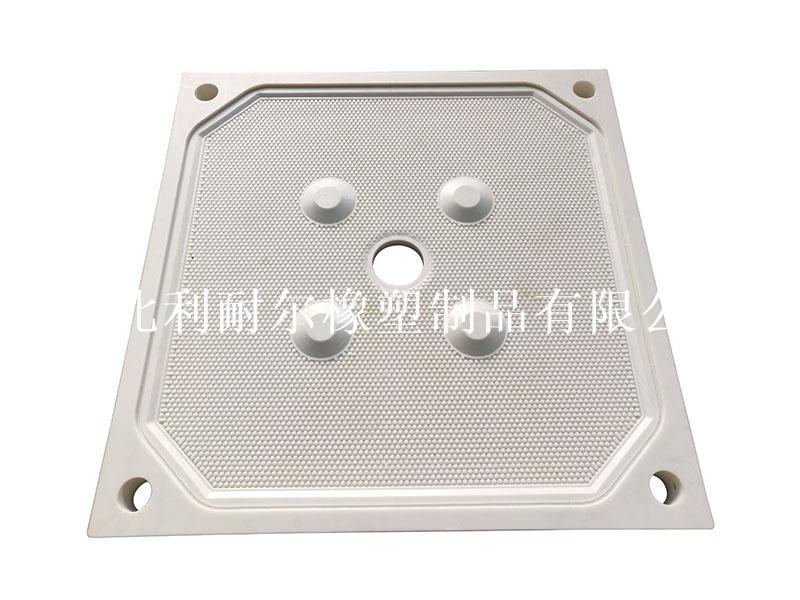

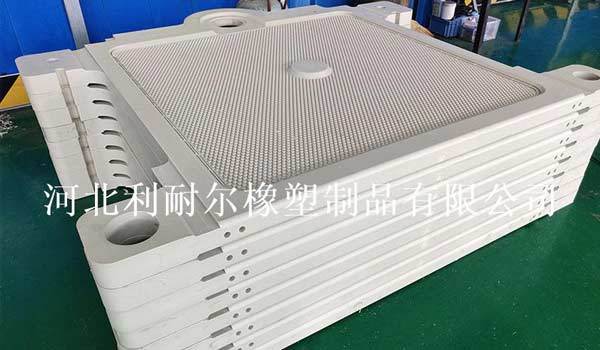

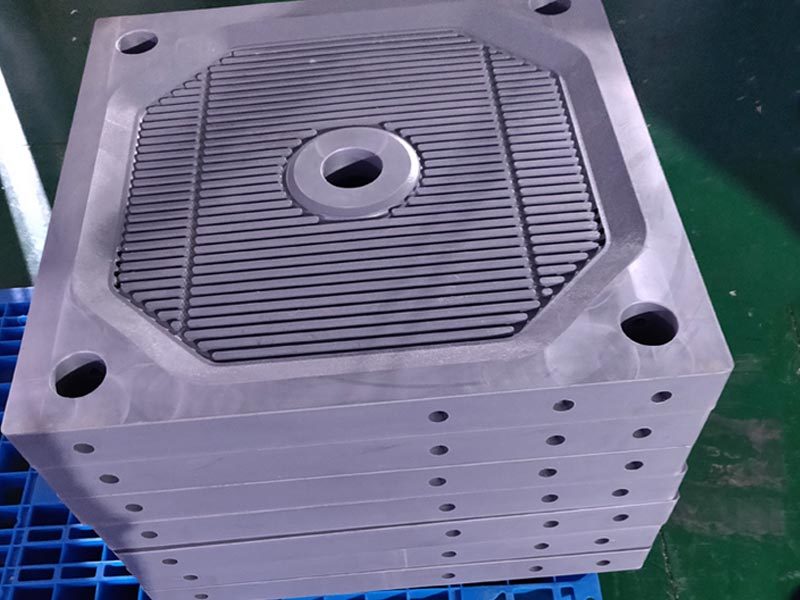

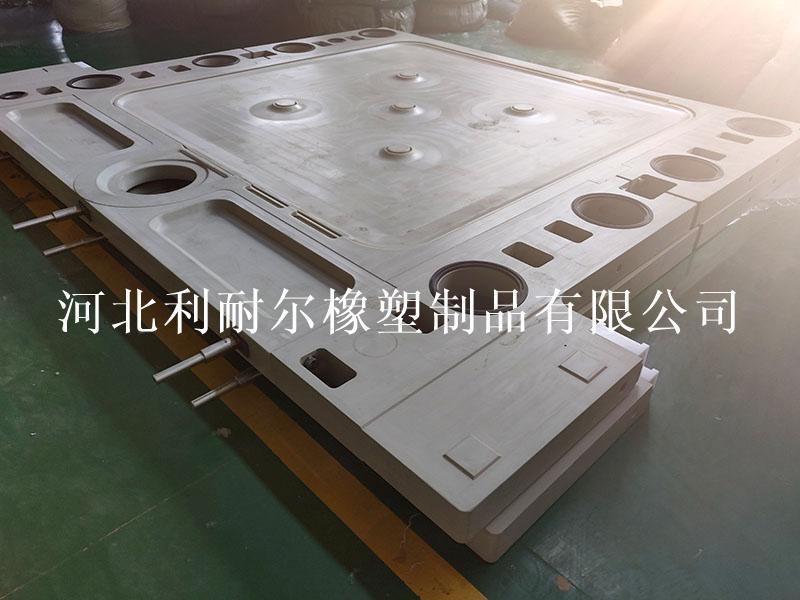

The dimensions of 800 ✘ 800 indicate a square-shaped filter plate, which is often utilized in filter presses, a common equipment used for solid-liquid separation. The size and shape are significant, as they affect the surface area available for filtration. A larger surface area can facilitate higher flow rates and improved filtration efficiency. The 800 ✘ 800 filter plate is typically manufactured from robust materials that can withstand high pressures and harsh chemical environments, ensuring durability and longevity in demanding industrial applications.

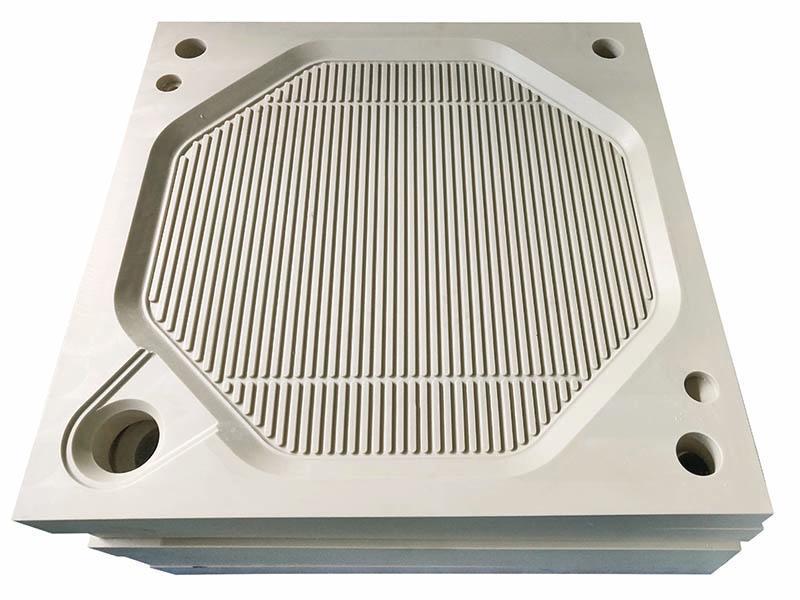

One of the primary functions of the 800 ✘ 800 filter plate is to provide a barrier that allows liquids to pass through while retaining solid particles. This separation is essential in processes where clarity and purity of the liquid are paramount. The design of the filter plate often includes strategically placed grooves or drainage channels that promote effective liquid flow and minimize clogging, which can lead to system inefficiencies.

In addition to their mechanical properties, the filter plates can be customized with different filter media, such as woven fabrics or non-woven materials, depending on the specific filtration needs. This versatility allows industries to select the appropriate filter media that aligns with their operational requirements, whether they are dealing with fine particulates or larger solids.

The installation and maintenance of the 800 ✘ 800 filter plate are straightforward, making it a user-friendly option for operators. Regular maintenance is crucial to ensure optimal performance; this includes periodic inspection and cleaning to prevent blockages and prolong the plate's lifespan.

Moreover, as industries increasingly focus on sustainability and environmental responsibility, the use of efficient filtration systems like those employing the 800 ✘ 800 filter plate can contribute to reduced waste generation and improved resource management. By ensuring that processes are as clean and efficient as possible, businesses can not only comply with regulatory standards but also promote a greener operational approach.

In conclusion, the 800 ✘ 800 filter plate is an indispensable component of industrial filtration systems. Its design, functionality, and adaptability make it suitable for a wide range of applications, enhancing the overall efficiency of purification processes. Understanding its importance can help professionals make informed decisions about their filtration needs, ultimately leading to improved operational outcomes.

The dimensions of 800 ✘ 800 indicate a square-shaped filter plate, which is often utilized in filter presses, a common equipment used for solid-liquid separation. The size and shape are significant, as they affect the surface area available for filtration. A larger surface area can facilitate higher flow rates and improved filtration efficiency. The 800 ✘ 800 filter plate is typically manufactured from robust materials that can withstand high pressures and harsh chemical environments, ensuring durability and longevity in demanding industrial applications.

One of the primary functions of the 800 ✘ 800 filter plate is to provide a barrier that allows liquids to pass through while retaining solid particles. This separation is essential in processes where clarity and purity of the liquid are paramount. The design of the filter plate often includes strategically placed grooves or drainage channels that promote effective liquid flow and minimize clogging, which can lead to system inefficiencies.

In addition to their mechanical properties, the filter plates can be customized with different filter media, such as woven fabrics or non-woven materials, depending on the specific filtration needs. This versatility allows industries to select the appropriate filter media that aligns with their operational requirements, whether they are dealing with fine particulates or larger solids.

The installation and maintenance of the 800 ✘ 800 filter plate are straightforward, making it a user-friendly option for operators. Regular maintenance is crucial to ensure optimal performance; this includes periodic inspection and cleaning to prevent blockages and prolong the plate's lifespan.

Moreover, as industries increasingly focus on sustainability and environmental responsibility, the use of efficient filtration systems like those employing the 800 ✘ 800 filter plate can contribute to reduced waste generation and improved resource management. By ensuring that processes are as clean and efficient as possible, businesses can not only comply with regulatory standards but also promote a greener operational approach.

In conclusion, the 800 ✘ 800 filter plate is an indispensable component of industrial filtration systems. Its design, functionality, and adaptability make it suitable for a wide range of applications, enhancing the overall efficiency of purification processes. Understanding its importance can help professionals make informed decisions about their filtration needs, ultimately leading to improved operational outcomes.

Related News